Nitric oxide doped carbon nanotube coating solid-phase microextraction fiber obtained based on chemical bonding method and application of nitric oxide doped carbon nanotube coating solid-phase microextraction fiber to detection of aromatic amine

A carbon nanotube and fiber extraction technology, applied in chemical instruments and methods, other chemical processes, measuring devices, etc., can solve problems such as difficulties, and achieve the effect of overcoming thermal instability and rapid enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

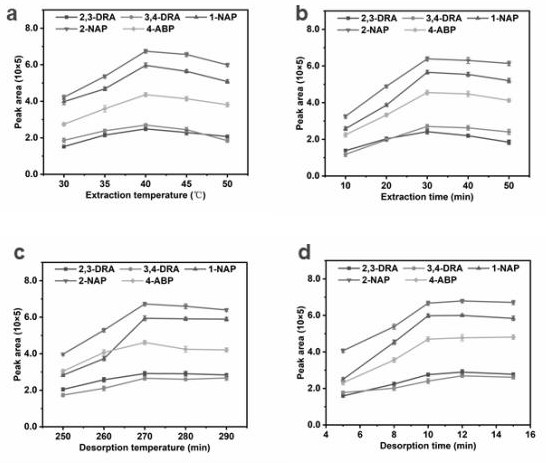

Examples

Embodiment 1

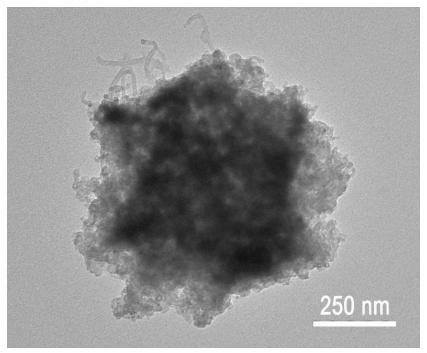

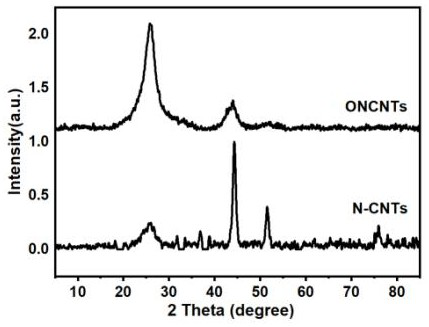

[0035] A kind of synthetic method of ONCNTs material, it comprises the following steps:

[0036] 1) Preparation of N-CNTs

[0037] (a) 2.0 g of dimethylimidazole and 1.7 g of cobalt nitrate hexahydrate were dissolved in 40.0 mL of a mixture of methanol and ethanol (the volume ratio of methanol and ethanol was 1:1). After the above solution was magnetically stirred for 20 s, it was placed at room temperature for 20 h;

[0038] (b) The resulting product was washed 5 times with methanol, and centrifuged at 8000 rpm for 5 min;

[0039] (c) After the obtained solid was dried at 70°C for 24 h, the ZIF-67 material was obtained;

[0040] (d) Add 200.0 mg of ZIF-67 into the crucible and place it in a tube furnace at 1°C min -1 The rate is raised to 700°C, and H 2 , kept for 2 h, and then gradually lowered to room temperature; finally black N-CNTs powder was obtained.

[0041] 2) Preparation of ONCNTs material

[0042] (a) Suspend 100.0 mg N-CNTs sample in 200.0 mL of 30% H 2 o ...

Embodiment 2

[0050] 1) Preparation of N-CNTs

[0051] (a) 2.0 g of dimethylimidazole and 1.7 g of cobalt nitrate hexahydrate were dissolved in 40.0 mL of a mixture of methanol and ethanol (the volume ratio of methanol and ethanol was 1:1). After the above solution was magnetically stirred for 20 s, it was placed at room temperature for 20 h;

[0052] (b) The resulting product was washed 5 times with methanol, and centrifuged at 8000 rpm for 5 min;

[0053] (c) After the obtained solid was dried at 70°C for 24 h, the ZIF-67 material was obtained;

[0054] (d) Add 200.0 mg of ZIF-67 into the crucible and place it in a tube furnace at 1°C min -1 The rate is raised to 700°C, and H 2 , kept for 2 h, and then gradually lowered to room temperature; finally black N-CNTs powder was obtained.

[0055] 2) Preparation of ONCNTs material

[0056] (a) Suspend 100.0 mg N-CNTs sample in 200.0 mL of 10 mol L -1 HCl solution, and stirred at room temperature for 6 h;

[0057] (b) After the obtained s...

Embodiment 3

[0064] 1) Preparation of N-CNTs

[0065] (a) 2.0 g of dimethylimidazole and 1.7 g of cobalt nitrate hexahydrate were dissolved in 40.0 mL of a mixture of methanol and ethanol (the volume ratio of methanol and ethanol was 1:1). After the above solution was magnetically stirred for 20 s, it was placed at room temperature for 20 h;

[0066] (b) The resulting product was washed 5 times with methanol, and centrifuged at 8000 rpm for 5 min;

[0067] (c) After the obtained solid was dried at 70°C for 24 h, the ZIF-67 material was obtained;

[0068] (d) Add 200.0 mg of ZIF-67 into the crucible and place it in a tube furnace at 1°C min -1 The rate is raised to 700°C, and H 2 , kept for 2 h, and then gradually lowered to room temperature; finally black N-CNTs powder was obtained 2) Preparation of ONCNTs material

[0069] (a) Suspend 100.0 mg N-CNTs sample in 200.0 mL of 12 mol L -1 HCl solution, and stirred at room temperature for 6 h;

[0070] (b) After the obtained suspension w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com