Graphene and ferrum diselenide composite material and method for preparing same

A technology of iron diselenide and composite materials, applied in the direction of binary selenium/tellurium compounds, chemical instruments and methods, carbon compounds, etc., to achieve the effects of low production cost, high specific surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put 0.5mmol sodium selenite pentahydrate and 1mmol ferrous sulfate into a 50mL polytetrafluoroethylene-lined stainless steel reaction kettle, add 6mL hydrazine hydrate and 10mL graphene oxide solution (water / ethylene glycol volume ratio 1 / 4) and mix them evenly, put them into the above reaction kettle, close and tighten the reaction kettle to make it airtight; put it in an oven, set the temperature at 180°C, take out the reaction kettle after 12 hours of reaction, and let it naturally Cool down; then pour out the reaction precipitate, wash it with distilled water three times, then wash it with absolute ethanol three times; finally dry it in a vacuum oven at 60°C for 8 hours, collect samples and store them in a desiccator.

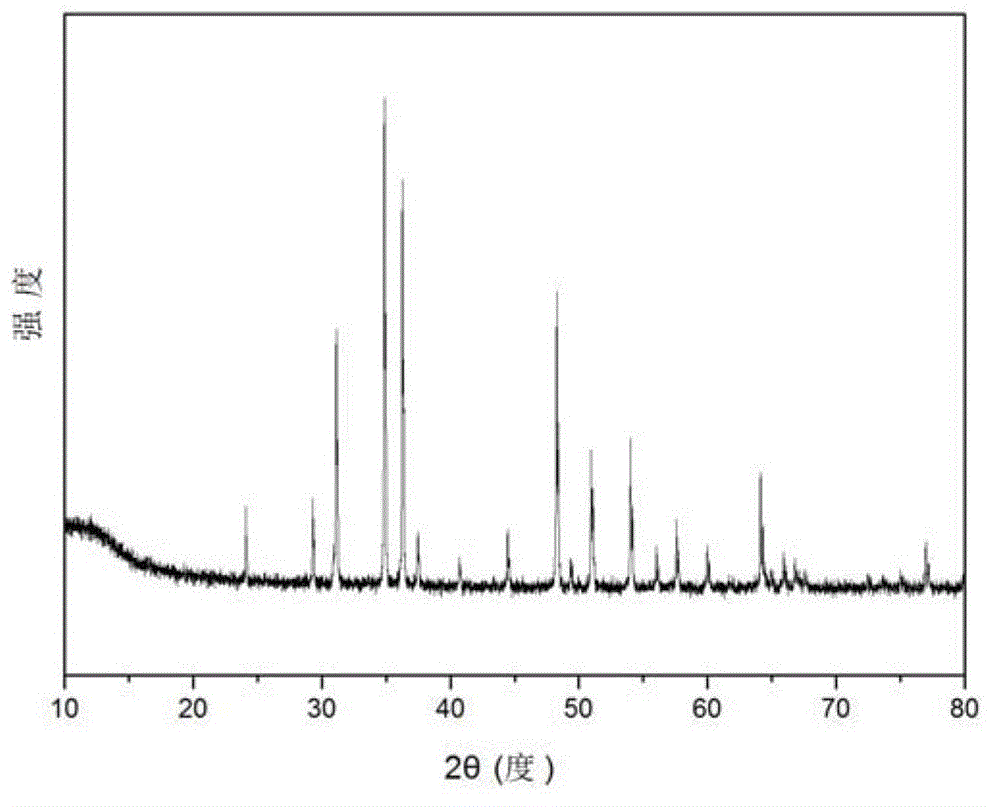

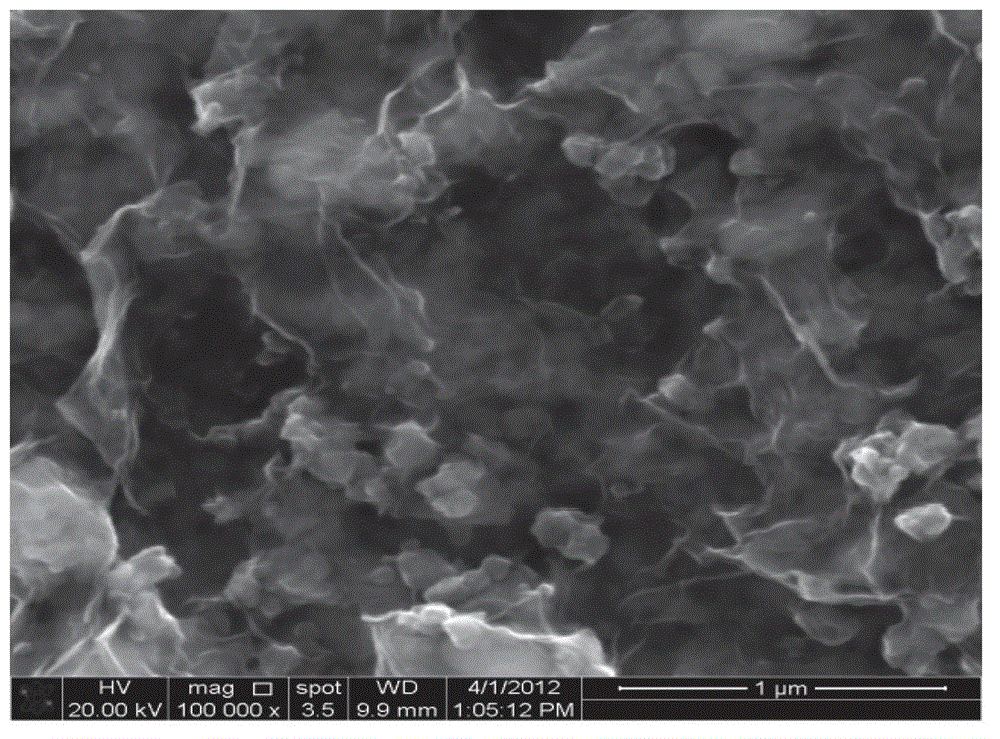

[0040] The XRD figure of the graphene / iron diselenide composite material prepared by the present embodiment is as follows figure 1 shown by figure 1 It can be seen that the obtained powder contains orthorhombic FeSe 2 (JCPD No.82-0269), the crystal...

Embodiment 2

[0042] Put 1mmol of sodium selenite pentahydrate and 0.5mmol of ferrous ammonium sulfate into a 50mL Teflon-lined stainless steel reaction kettle, add 8mL of hydrazine hydrate and 15mL of graphene oxide solution (water / ethylene glycol volume ratio of 1 / 4) and mix them evenly, put them into the above reaction kettle, close and tighten the reaction kettle to make it airtight; put it in an oven, set the temperature at 120°C, take out the reaction kettle after 15 hours of reaction, and make it Cool naturally; then pour out the reaction precipitate, first wash three times with distilled water, then wash three times with absolute ethanol; finally dry in a vacuum oven at 60°C for 7 hours, collect samples and store them in a desiccator.

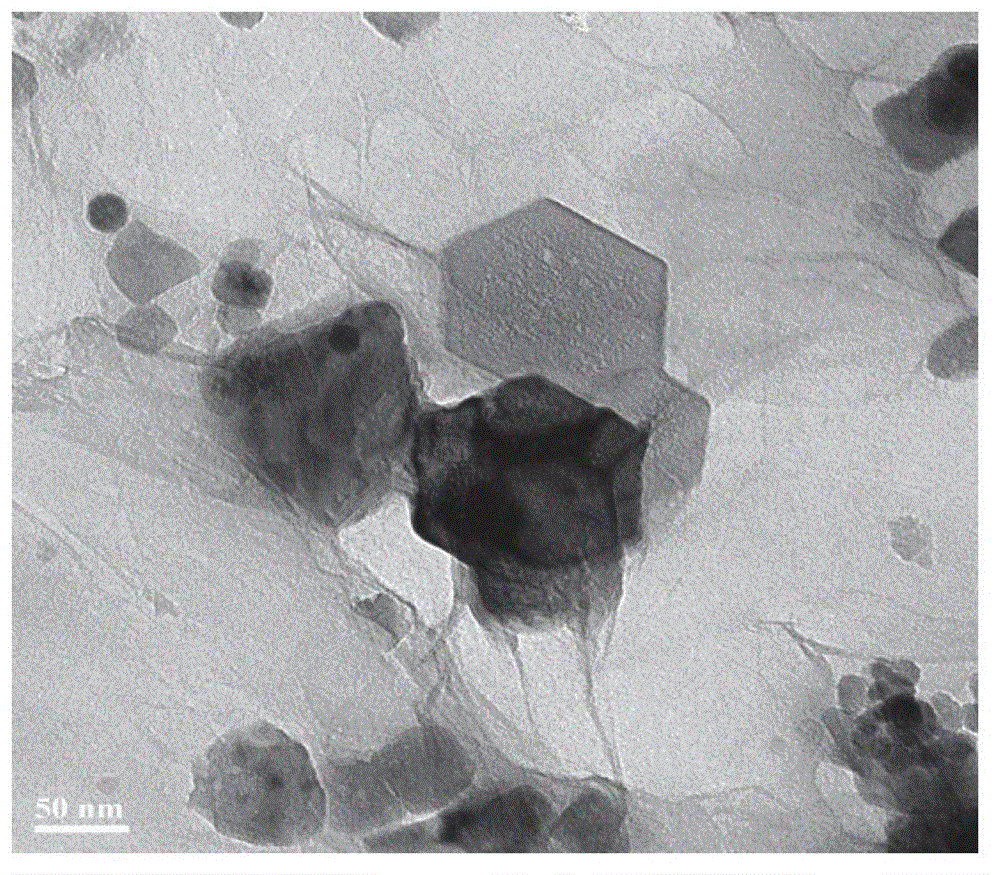

[0043] Figure 6 The TEM figure of the sample prepared for this embodiment, this figure shows the rod-shaped FeSe prepared as a result 2 Evenly dispersed on graphene, its length is 20nm ~ 150nm; a single FeSe 2 HRTEM image of nanorods ( Figure 7 ...

Embodiment 3

[0045] Put 0.5mmol sodium selenite pentahydrate and 1mmol ferrous sulfate into a 50mL polytetrafluoroethylene-lined stainless steel reaction kettle, add 8mL hydrazine hydrate and 20mL graphene oxide solution (water / ethylene glycol volume ratio 1 / 4) and mix them evenly, put them into the above reaction kettle, close and tighten the reaction kettle to make it airtight; put it in an oven, set the temperature at 180°C, take out the reaction kettle after 12 hours of reaction, and let it naturally Cool down; then pour out the reaction precipitate, wash it with distilled water three times, then wash it with absolute ethanol three times; finally dry it in a vacuum oven at 60°C for 8 hours, collect samples and store them in a desiccator.

[0046] In the prepared composite material, FeSe 2 It is in the shape of spherical particles, which are relatively uniformly distributed on the graphene sheet, and the average particle size is 100nm-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com