Method for preparing prickly ash seed oil through mechanical compression

A technology of prickly ash seed oil and mechanical pressing, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of high cost, unfavorable food health, complicated process, etc., achieve high oil production rate, eliminate chemical The effect of the introduction of ingredients and the simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

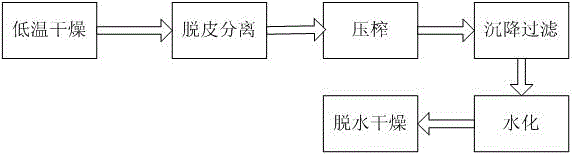

Image

Examples

specific Embodiment 1

[0018] Step 1. Dry the pepper seeds, cool the pepper seeds to 30 degrees Celsius in the form of blowing cold air, and reduce the water content of the pepper seeds to 6%.

[0019] Using the low-temperature dehydration method, compared with the previous hot air drying method, the linoleic acid and linolenic acid in the pepper seed oil can be kept to the maximum extent, and will not decompose at high temperature and lose with water.

[0020] Step 2. Peeling the pepper seeds to reduce the mass percentage of the pepper seeds in the pepper seeds to below 10%.

[0021] If the seed skin of Zanthoxylum bungeanum is not removed, in the subsequent pressing process, the skin will produce substances that destroy the unsaturated fatty acid components in the Zanthoxylum bungeanum oil, and at the same time affect the aroma and purity of the final finished Zanthoxylum bungeanum oil, so it should be as possible Remove pepper seed skin.

[0022] Step 3. Press the peeled pepper seeds to obtain c...

specific Embodiment 2

[0025] Step 1. Dry the pepper seeds, cool the pepper seeds to 30 degrees Celsius in the form of blowing cold air, and reduce the water content of the pepper seeds to 10%.

[0026] The step 1 also includes a step of removing iron and sand, using a sieve larger than 200 mesh to filter the sand contained in the pepper seeds, and electromagnets can also be used to absorb the iron sand contained in the pepper seeds to remove these impurities with high hardness and avoid Abrasion of the anti-corrosion coating on contact surfaces that destroy machinery and equipment during subsequent pressing.

[0027] Step 2. Peeling the pepper seeds, so that the mass percentage of the pepper seeds in the pepper seeds is reduced to below 7%.

[0028] Step 3. Press the peeled pepper seeds to obtain crude oil. After sedimentation and filtration, the crude oil is sent to a hydration tank for hydration treatment. After hydration is completed, dehydration and drying are carried out.

specific Embodiment 3

[0029] Step 1. Dry the pepper seeds, cool the pepper seeds to 20 degrees Celsius in the form of blowing cold air, and reduce the water content of the pepper seeds to 6%.

[0030] The step 1 also includes a step of removing iron and sand, using a sieve larger than 200 mesh to filter the sand contained in the pepper seeds, and electromagnets can also be used to absorb the iron sand contained in the pepper seeds to remove these impurities with high hardness and avoid Abrasion of the anti-corrosion coating on contact surfaces that destroy machinery and equipment during subsequent pressing.

[0031] Step 2. Peeling the pepper seeds, so that the mass percentage of the pepper seeds in the pepper seeds is reduced to below 7%. During the peeling process in step 2, the temperature is not higher than 30 degrees Celsius, and the peeling operation is performed at a low temperature, so that the linoleic acid and linolenic acid in the pepper seed oil can be kept to the maximum, and will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com