Extraction method of rose essential oil as well as rose essential oil

A technology of rose essential oil and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of unevenness, easy bonding of roses into layers, insufficient cooking, etc., and achieve the goal of improving oil production rate and quality of essential oil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

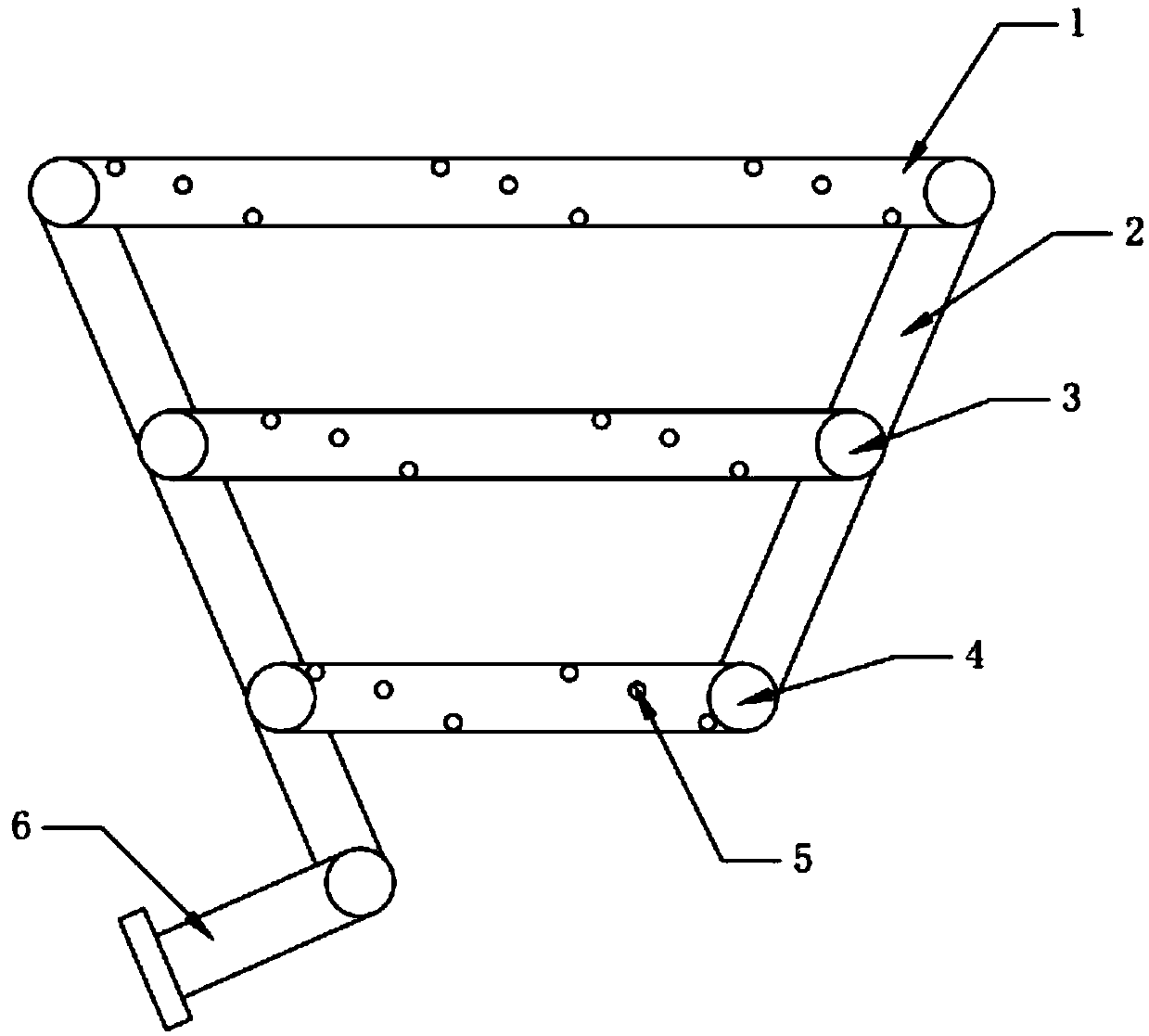

[0043] The extraction method of the rose essential oil of this specific embodiment comprises the following steps: A, raw material processing: adding 400 kilograms of rose fresh flowers (or the net weight of rose flowers after removing the weight of edible salt when pickling fresh flowers) into a 3m thick pot with a diameter of φ1750mm 3 Inside the still; B. Steam tumbling distillation: steam is passed into the still, and the steam enters the still in the form of vertical multi-layer interval distribution, so that the roses are tumbling and distilled, and the initial steam pressure value is 0.04 MPa; after confirming that the condensed water mixed with oil and water flows out from the condensed water outlet, control the temperature of the condensed water outlet for the first time adjustment to 12°C. 5L / min, the distillation time (steam introduction time) is 2h; then, control the second time to adjust the temperature of the condensed water outlet to 25°C, correspondingly, it is n...

Embodiment 2

[0045] The extraction method of the rose essential oil of this specific embodiment comprises the following steps: A, raw material processing: adding 400 kilograms of rose fresh flowers (or the net weight of rose flowers after removing the weight of edible salt when pickling fresh flowers) into a 3m thick pot with a diameter of φ1750mm 3 Inside the still; B. Steam tumbling distillation: steam is passed into the still, and the steam enters the still in the form of vertical multi-layer interval distribution, so that the roses are tumbling and distilled, and the initial steam pressure value is 0.04 MPa; after confirming that the condensed water mixed with oil and water flows out from the condensed water outlet, control the temperature of the condensed water outlet for the first time adjustment to 18°C. 4.5L / min, the distillation time (steam introduction time) is 2h; then, control the second time to adjust the temperature of the condensate outlet to 30°C, correspondingly, it is nece...

Embodiment 3

[0047] The extraction method of the rose essential oil of this specific embodiment comprises the following steps: A, raw material processing: adding 400 kilograms of rose fresh flowers (or the net weight of rose flowers after removing the weight of edible salt when pickling fresh flowers) into a 3m thick pot with a diameter of φ1750mm 3 Inside the still; B. Steam tumbling distillation: steam is passed into the still, and the steam enters the still in the form of vertical multi-layer interval distribution, so that the roses are tumbling and distilled, and the initial steam pressure value is 0.04 MPa; after confirming that the condensed water mixed with oil and water flows out from the condensed water outlet, control the temperature of the condensed water outlet for the first time adjustment to 25°C. 4.6L / min, the distillation time (steam introduction time) is 2h; then, control the second time to adjust the temperature of the condensate outlet to 35°C, correspondingly, it is nece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com