Quick hydropyrolysis reactor and process thereof

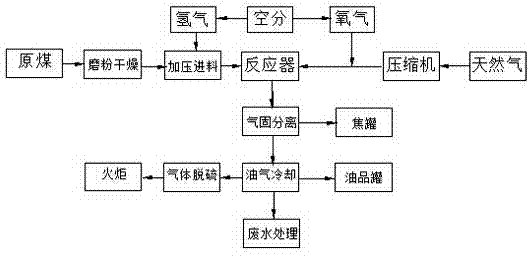

A technology of hydropyrolysis and pyrolysis reaction, which is applied in the field of coal-to-oil, which can solve the problems of low equipment production capacity, high equipment investment cost, water consumption, and large hydrogen consumption, so as to achieve increased production rate and low CO2 emissions , the effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

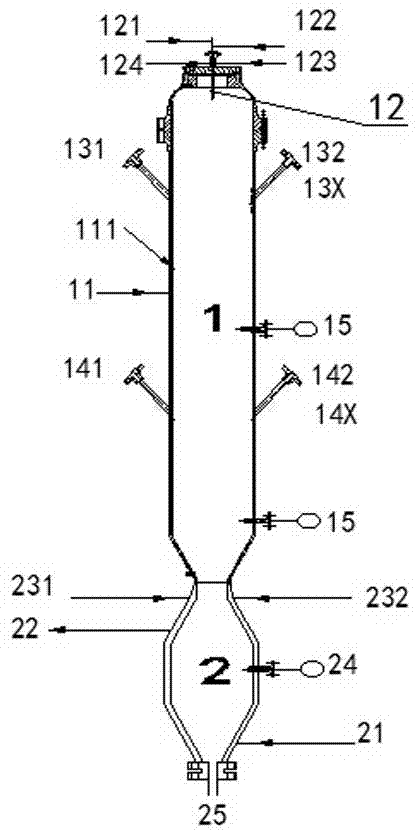

[0027] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. The present invention can have various changes in different embodiments without departing from the scope of protection of the present invention, and the descriptions and illustrations therein are used for illustration in essence rather than limiting the present invention.

[0028] like figure 1 As shown, a fast hydropyrolysis reactor is composed of a reactor 1 and a chill tank 2. The shell 11 of the reactor 1 is lined with a refractory material 111, and the top of the reactor 1 is installed Synthesis gas nozzle 12, hydrogen nozzle 131 / 132 / 13X installed in the middle and upper part, pulverized coal nozzle 141 / 142 / 14X installed in the middle and lower part, the middle and lower parts of the reactor 1 are respectively equipped with reactor temperature measuring points 15, the synthesis The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com