Simple preparation method of hollow cerium oxide nano-spheres

A technology of nanospheres and cerium oxide, applied in the field of nanomaterials, can solve the problems of strict reaction conditions, cumbersome treatment process, unsatisfactory raw material cost control, etc., and achieve high applicability, low environmental pollution, and controllable reaction results adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

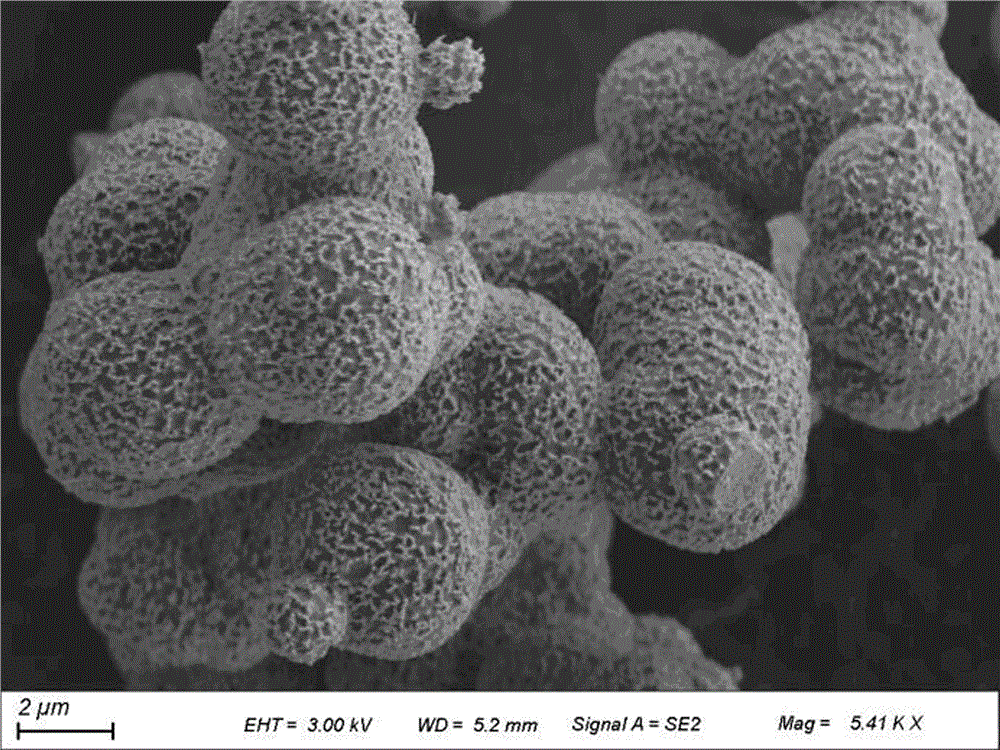

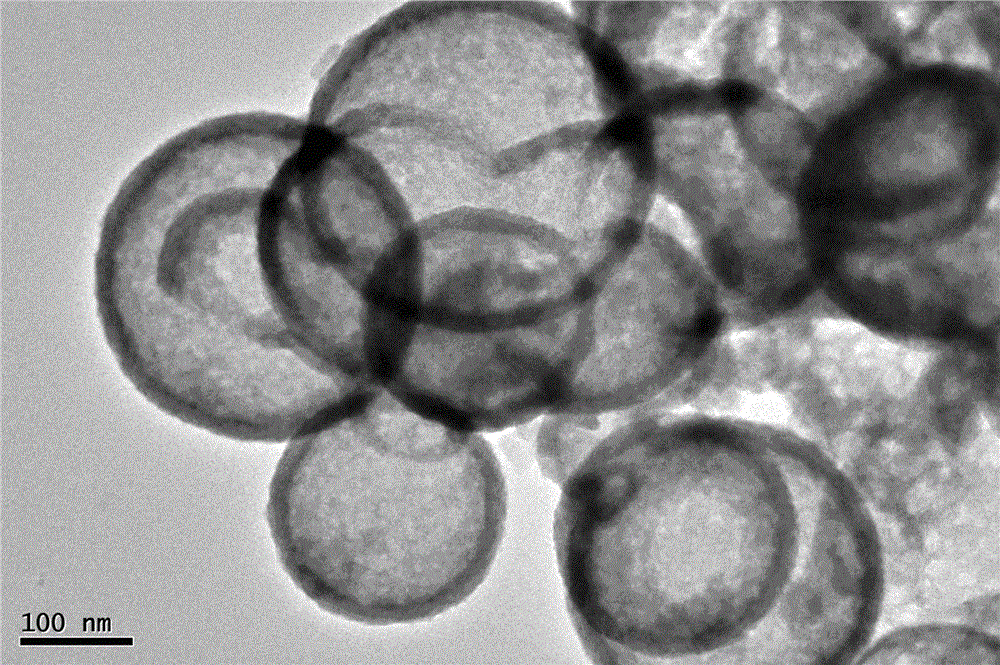

[0017] Such as Figure 1-2 Shown, the present invention is a kind of simple preparation method of hollow nanosphere cerium oxide, and described preparation method comprises the following steps:

[0018] (1) Weigh cerium trichloride heptahydrate and L-cysteine respectively, mix them and add them to the reaction solvent water or absolute ethanol, stir evenly to obtain suspension A,

[0019] (2) Pour the uniformly stirred suspension A into the inner tank of the hydrothermal kettle, and the filling rate is 60%. After the autoclave is tightened, put it in a vacuum drying oven at 160-200°C for 3-24 hours. Get the product in the liner;

[0020] (3) After the reaction is over, stop heating and let the reactor cool down to room temperature naturally, take the product in the liner and centrifuge to remove by-products, and then wash with deionized water for 3 times and absolute ethanol for 1 time. The cerium oxide hollow nanospheres can be obtained after being dried under the sun.

...

Embodiment 1

[0024] Mix 0.3 g of cerium trichloride heptahydrate and 0.3 gL-cysteine into a hot-pressed hydrothermal kettle with a capacity of 100 mL, then add 60 mL of water, and the filling rate is 60%; then the reaction kettle is sealed and Heat to 180°C for 24 hours; after the reaction, stop heating and allow the reactor to cool down to room temperature naturally; then wash the product with deionized water and absolute ethanol successively and centrifuge to remove by-products and impurities, and dry the product at 40°C After that, the cerium oxide hollow nanospheres can be obtained.

[0025] The scanning electron micrograph of gained cerium oxide hollow nanosphere is shown in figure 1 , the transmission electron microscope photo see figure 2 , it can be seen that the obtained samples are all regular spherical, and the broken nanospheres can be obtained as a hollow structure. The shell thickness of the nanospheres is about 10 nm, and the inner diameter of the hollow spheres ranges f...

Embodiment 2

[0026] Embodiment 2: The preparation method is the same as Example 1, except that the reaction time is changed from 24 hours to 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com