A kind of preparation method of cerium sulfide doped carbon quantum dot nano fluorescent material

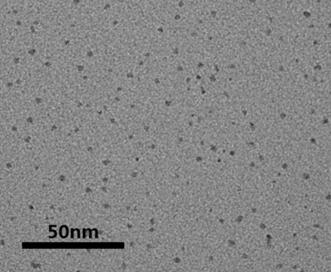

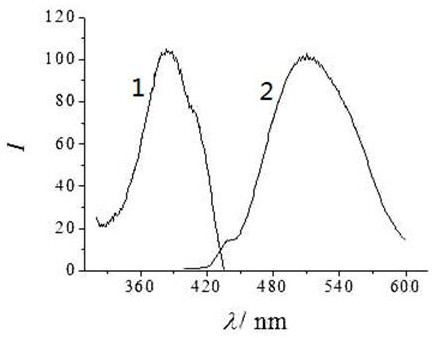

A technology of carbon quantum dots and nano-fluorescence, which is applied in the field of preparation of nano-luminescent materials, can solve the problems of inability to accurately control the lateral size and surface chemistry, the low fluorescence quantum yield of the synthesis method, and the unclear luminescence mechanism, etc., and achieve the improvement of fluorescence performance , Uniform size, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

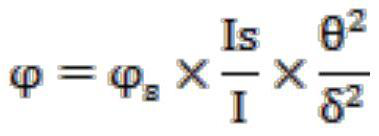

Examples

Embodiment 1

[0021] (1) Preparation of liquid A: In the reactor, add deionized water: 64mL, itaconic acid: 34g, cerium trichloride: 2g, stir and dissolve to obtain liquid A;

[0022] (2) Preparation of liquid B: in the reactor, add deionized water: 93mL, thioacetamide: 7g, stir and dissolve to obtain liquid B;

[0023] (3) Preparation of crude product cerium sulfide doped carbon quantum dot nano fluorescent material: add liquid A: 50mL in the reactor, stir, dropwise add liquid B: 10mL to liquid A, dropwise, stir for 30min, transfer to In the reaction kettle, cover the sealed cover, place it in a constant temperature box, keep the temperature at 180±2°C, and react for 22 hours to obtain a red suspension liquid, which is separated from the solid and liquid, and the liquid is crude cerium sulfide doped carbon quantum dot nano-fluorescent material;

[0024] (4) Purification of cerium sulfide-doped carbon quantum dot nano fluorescent material: the liquid obtained in step (3) is injected into a ...

Embodiment 2

[0026] (1) Preparation of liquid A: In the reactor, add deionized water: 62mL, itaconic acid: 35.5g, cerium trichloride: 2.5g, stir and dissolve to obtain liquid A;

[0027] (2) Preparation of liquid B: in the reactor, add deionized water: 92mL, thioacetamide: 8g, stir and dissolve to obtain liquid B;

[0028] (3) Preparation of crude product cerium sulfide doped carbon quantum dot nano fluorescent material: add liquid A: 100mL in the reactor, stir, dropwise add liquid B: 20mL to liquid A, dropwise, stir for 30min, transfer to In the reaction kettle, cover the sealed cover, place it in an incubator, keep the temperature at 180±2°C, and react for 20 hours to obtain a red suspension liquid, which is separated from the solid and liquid, and the liquid is crude cerium sulfide doped carbon quantum dot nano-fluorescence material;

[0029] (4) Purification of cerium sulfide-doped carbon quantum dot nano fluorescent material: the liquid obtained in step (3) is injected into a dialysis...

Embodiment 3

[0031] (1) Preparation of liquid A: In the reactor, add deionized water: 66mL, itaconic acid: 32.5g, cerium trichloride: 1.5g, stir and dissolve to obtain liquid A;

[0032] (2) Preparation of liquid B: In the reactor, add deionized water: 94mL, thioacetamide: 6g, stir and dissolve to obtain liquid B;

[0033] (3) Preparation of crude product cerium sulfide doped carbon quantum dot nano fluorescent material: add liquid A: 150mL in the reactor, stir, dropwise add liquid B: 30mL to liquid A, dropwise, stir for 30min, transfer to In the reaction kettle, cover the sealed cover, place it in a constant temperature box, keep the temperature at 180±2°C, and react for 24 hours to obtain a red suspension liquid, which is separated from the solid and liquid, and the liquid is crude cerium sulfide doped carbon quantum dot nano fluorescent material;

[0034] (4) Purification of cerium sulfide-doped carbon quantum dot nano fluorescent material: the liquid obtained in step (3) is injected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com