2,3',5,5'-diphenyl tetracarboxylic acid cadmium complex and preparation method thereof

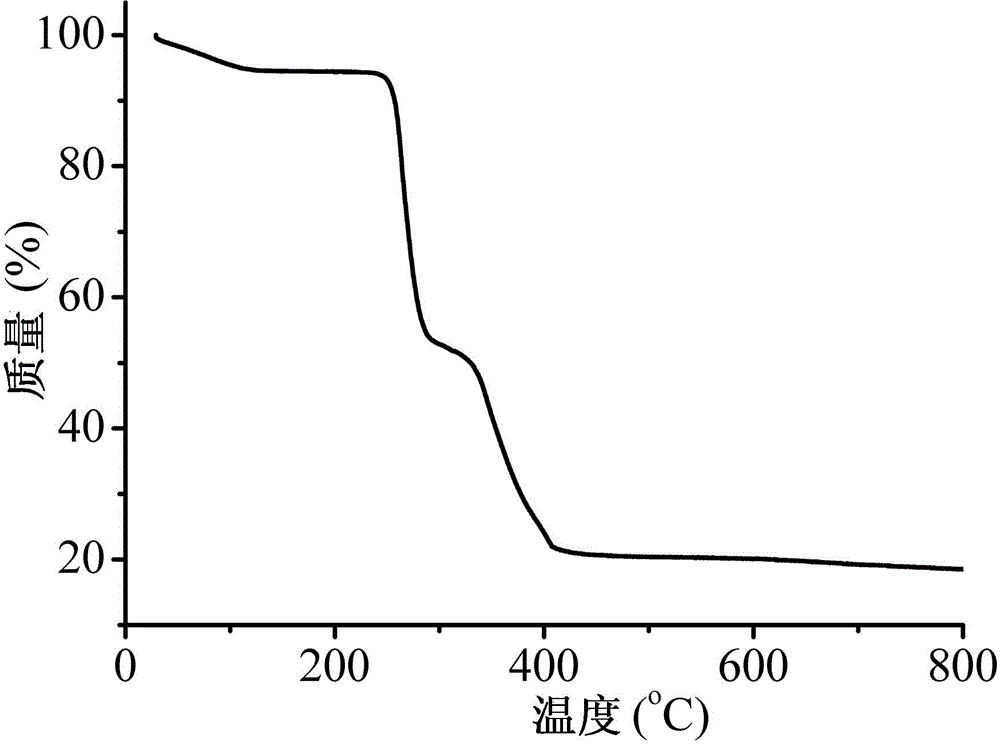

A technology of diphthalic acid and cadmium complexes, which is applied in the directions of cadmium organic compounds, chemical instruments and methods, luminescent materials, etc., to achieve the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix 0.1 mmol (33.0 mg) of 2,3′,5,5′-dibenzenetetracarboxylic acid, 0.1 mmol (5.6 mg) of potassium hydroxide, 0.1 mmol (21.8 mg) of bih with 0.1 mmol (26.6 mg) of Cadmium acetate was dissolved in 12 mL of water to make a mixed solution, and the mixed solution was added to a 25 mL closed reaction kettle, heated to 120 °C at a rate of 10 °C per hour, and maintained at this temperature for 3 days, and then naturally cooled to room temperature , the colorless massive crystals can be obtained, the crystals are separated, washed and dried successively, and finally the target product is obtained with a yield of about 52%. The main infrared absorption peaks are: 3124 m, 2938 m, 2360 m, 2341 s, 1601 s, 1541 s, 1428 m, 1396 m, 1274 s, 1239 s, 1111 s, 1087 s, 1063 s, 1030 m, 939 s, 913s, 848s, 772s, 706s.

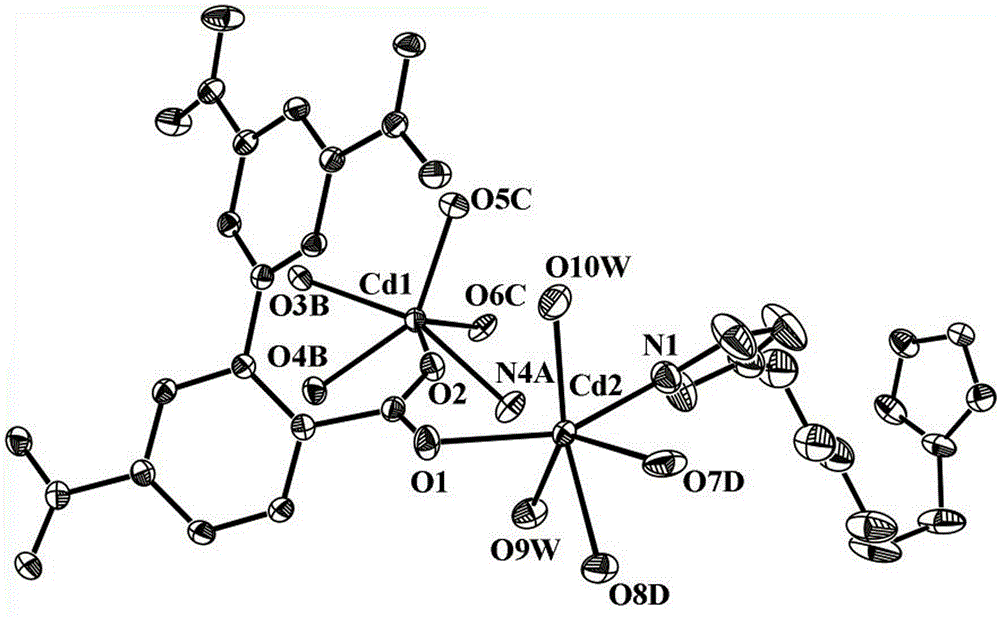

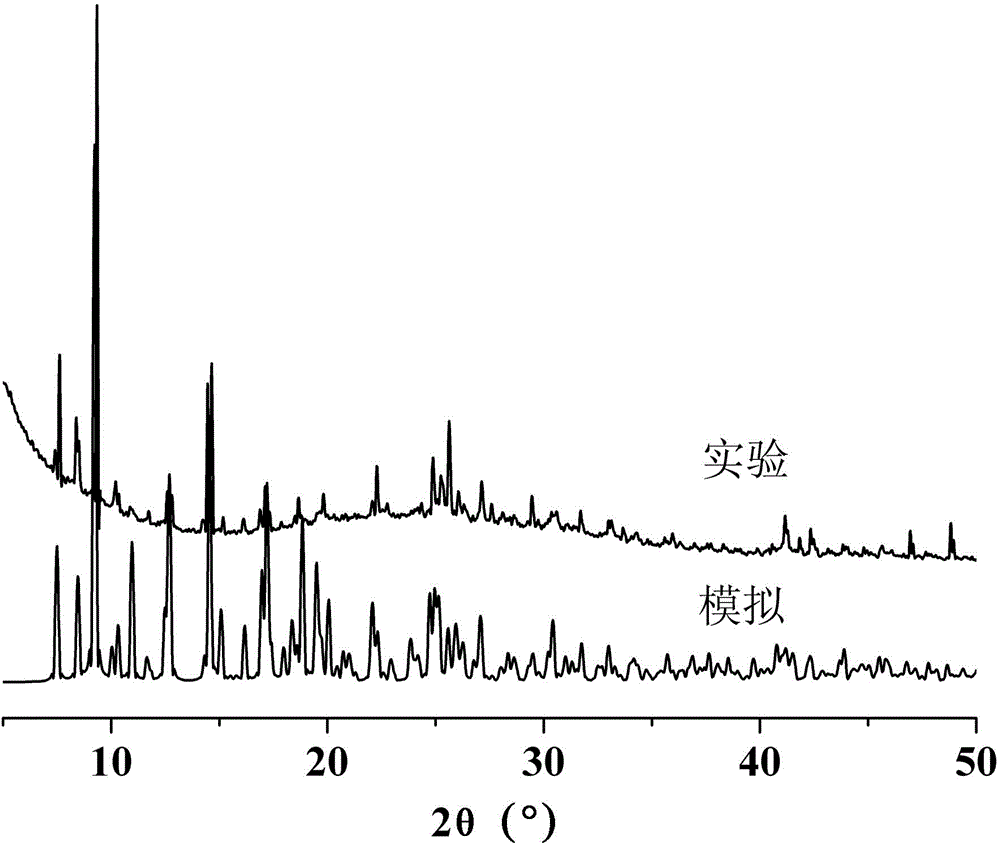

[0023] The cadmium complex of 2,3',5,5'-diphenyltetracarboxylate prepared in Example 1 was further characterized, and the process is as follows:

[0024] (1) Determination of ...

Embodiment 2

[0042] Mix 0.06 mmol (19.8 mg) of 2,3′,5,5′-dibenzenetetracarboxylic acid, 0.18 mmol (10.08 mg) of potassium hydroxide, 0.06 mmol (13.1 mg) of bih with 0.18 mmol (43.9 mg) of Cadmium acetate was dissolved in 12 mL of water to make a mixed solution, and the mixed solution was added to a 25 mL closed reaction kettle, heated to 130 °C at a rate of 10 °C per hour, and maintained at this temperature for 3 days, and then naturally cooled to room temperature , to obtain colorless massive crystals, the crystals were separated, washed and dried successively to obtain the target product with a yield of about 51%.

Embodiment 3

[0044] Mix 0.18 mmol (59.4 mg) of 2,3′,5,5′-dibenzenetetracarboxylic acid, 0.06 mmol (2.4 mg) of sodium hydroxide, 0.18 mmol (39.3 mg) of bih with 0.06 mmol (14.6 mg) of Cadmium acetate was dissolved in 12 mL of water to make a mixed solution, and the mixed solution was added to a 25 mL closed reaction kettle, heated to 130 °C at a rate of 10 °C per hour, and maintained at this temperature for 3 days, and then naturally cooled to room temperature , the colorless massive crystals can be obtained, the crystals are separated, washed and dried successively to obtain the target product with a yield of about 47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com