Red fluorescent material and method for preparing same

A technology of red fluorescent and fluorescent materials, which is applied in the field of red fluorescent materials and their preparation, can solve the problems of poor performance and achieve the effects of good repeatability, excellent fluorescent performance, and easy control of chemical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 0.156g of 2,5-furandicarboxylic acid, 0.101g of potassium nitrate, and 0.446g of europium nitrate to form a mixture, add it to 50ml of acetonitrile solution, stir for 10 minutes, and then put it in an oven at 120°C for 48 hours, Cooling to obtain colorless massive crystals, which is the red fluorescent material [Eu 3 K 2 (FDA) 4 (NO 3 ) 3 (MeCN) 2 ] n .

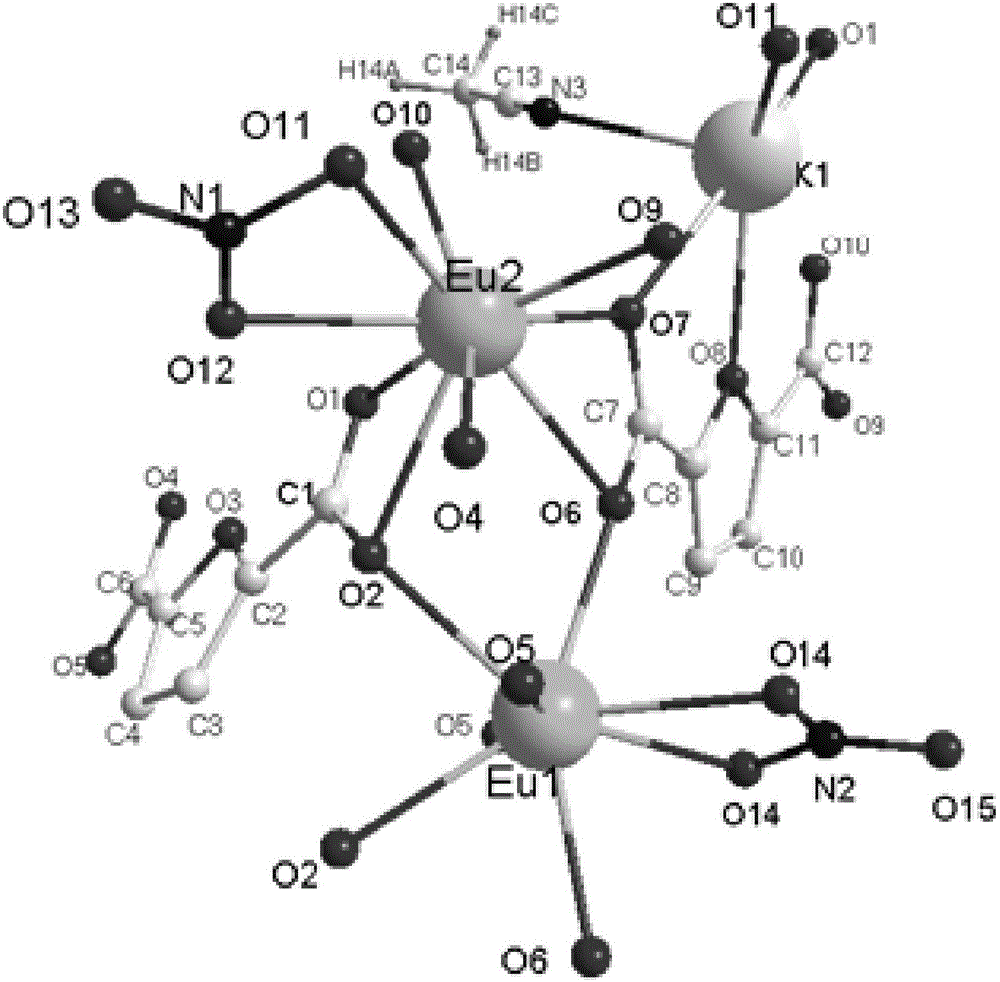

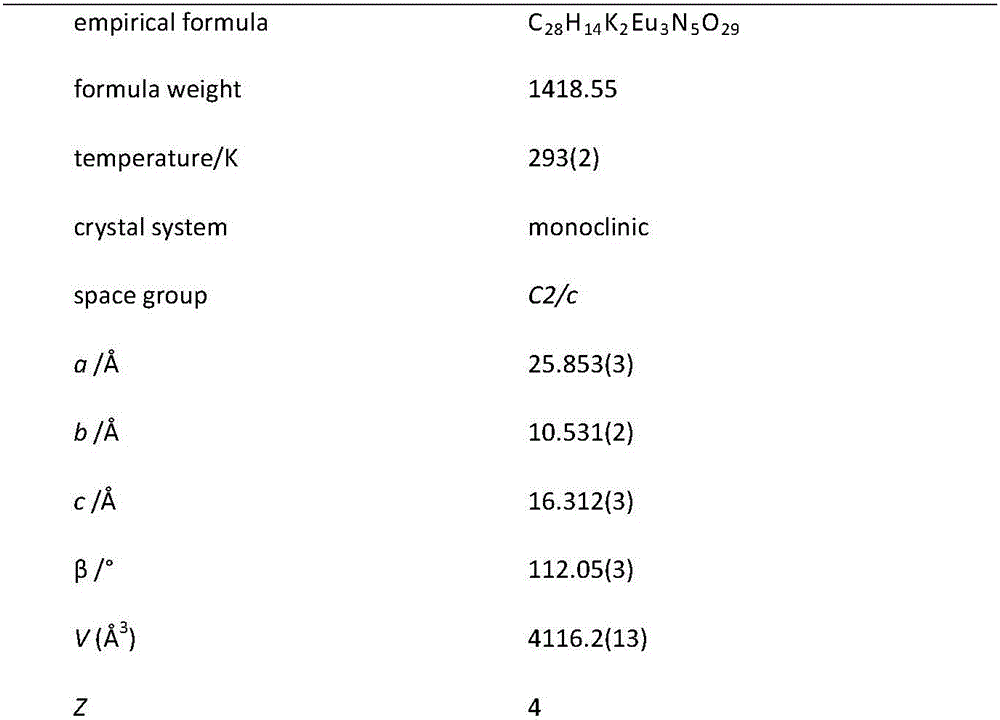

[0035] Use the following instruments and methods to characterize the product: 1. Select crystals with a size of 0.27×0.26×0.24mm for single crystal structure analysis. The single crystal diffraction data are collected on the Rigaku SCX diffractometer and monochromated with a graphite monochromator Mok alpha rays ( ), 3.1°≤θ≤27.5°. The obtained compound belongs to the monoclinic crystal system, the space group is all C2 / c, and the unit cell parameters are approximately α=90°, β=112.05°, γ=90°. The crystal structure of the fluorescent material is shown in figure 1 (drawn using Diamond software).

Embodiment 2

[0037] Mix 0.312g of 2,5-furandicarboxylic acid, 0.202g of potassium nitrate, and 0.892g of europium nitrate, then add it to 100ml of acetonitrile solution, stir for 10 minutes, then put it in an oven at 120°C for 48 hours, then cool A colorless bulk crystal is obtained, which is the red fluorescent material [Eu 3 K 2 (FDA) 4 (NO 3 ) 3 (MeCN) 2 ] n .

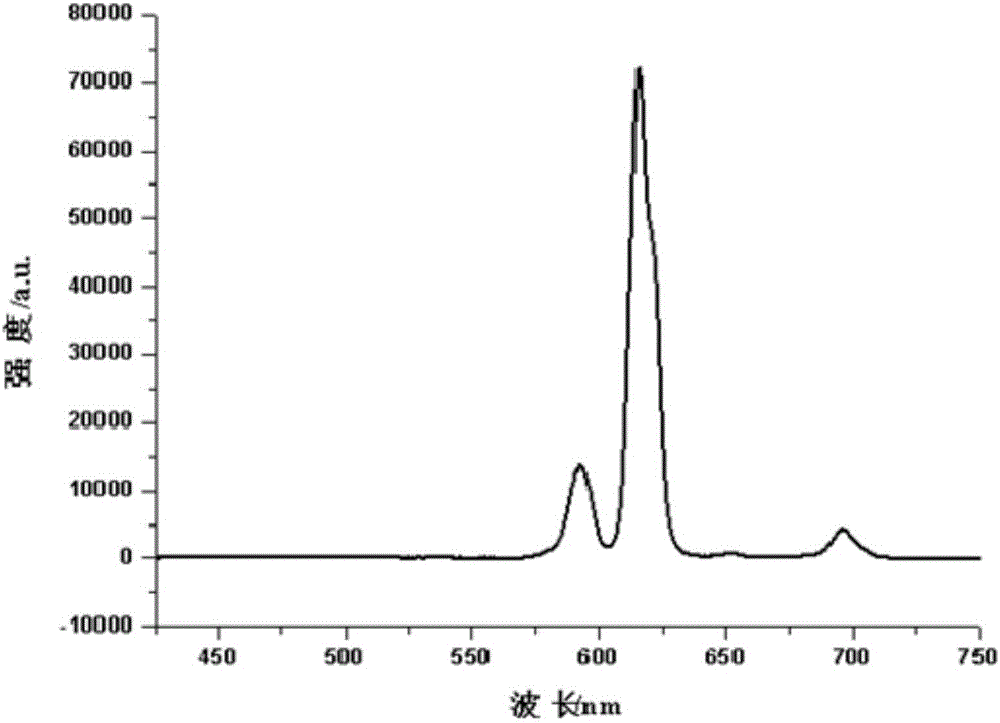

[0038] The red fluorescent material [Eu 3 K 2 (FDA) 4 (NO 3 ) 3 (MeCN) 2 ] n Fluorescence test is carried out, which produces red fluorescence with an intensity of 70000a.u. under the irradiation of 395nm incident light, and the result of the fluorescence spectrum curve is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com