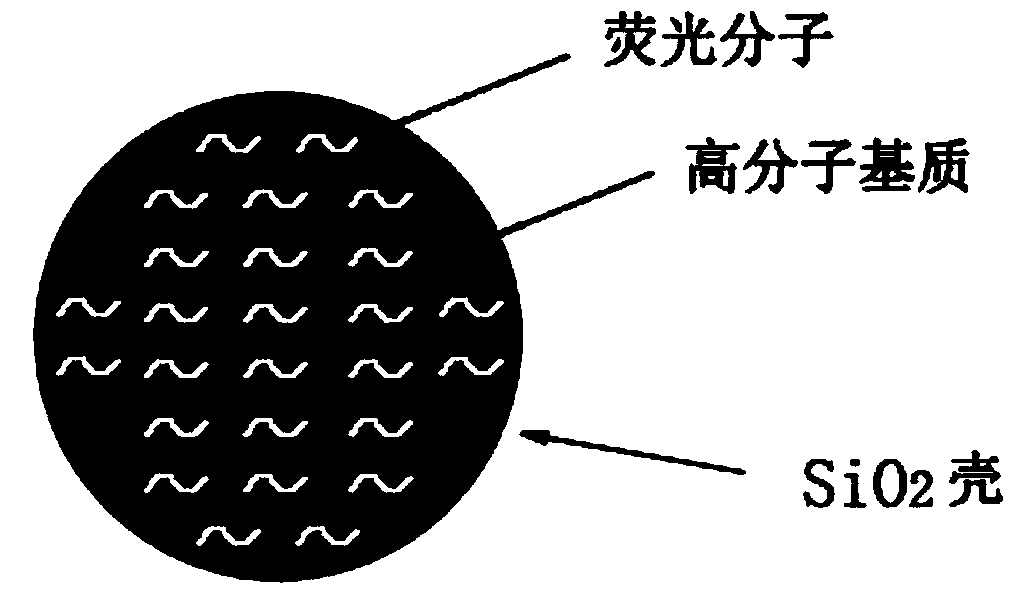

Fluorescent microsphere of core shell structure and preparing method and application thereof

A technology of fluorescent microspheres and core-shell structures, which is applied to the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of troublesome preparation, few types of dyes, and low luminous intensity of fluorescent microspheres, and achieve fluorescent performance Excellent, good application prospects, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Example 1: (1) Preparation of the first polymer core: Take 100mL of purified water, add 10g of rectified styrene, 1.5g of PVP (polyvinylpyrrolidone) and 0.26g of AIBN (azobisisobutyronitrile) Put it into a 250mL three-necked flask equipped with a stirrer, a thermometer and a condenser, ultrasonically disperse for 10 minutes, stir for 1 hour under nitrogen protection, set the stirring rate at 450r / min, then slowly raise the temperature to 70°C, and continue the reaction for 12 hours. After lowering the temperature to room temperature, stop stirring, remove the nitrogen gas, centrifuge the product, wash thoroughly with ethanol, and freeze-dry to obtain the first polymer core with a particle size of 240nm and a monodispersity of less than 5%.

[0032] (2) Preparation of the second polymer core dispersed with fluorescent dyes: Take 2 grams of the prepared first polymer core, 20 mL of purified water, and 0.8 g of acrylic acid Pluronic F127 into a 50 mL single-necked flask, and...

Embodiment 3

[0041] Example 3: (1) Preparation of the first polymer core: Take 100mL of purified water, add 20g of rectified styrene, 1.5g of PVP (polyvinylpyrrolidone) and 0.20g of AIBN (azobisisobutyronitrile) Put it into a 250mL three-necked flask equipped with a stirrer, a thermometer and a condenser, ultrasonically disperse for 15 minutes, stir for 1 hour under nitrogen protection, set the stirring rate at 480r / min, then slowly raise the temperature to 70°C, and continue the reaction for 12 hours. After the temperature was lowered to room temperature, the stirring was stopped, the nitrogen was removed, the product was centrifuged and fully washed with ethanol, and freeze-dried to obtain the first polymer core with a particle size of 460nm and a monodispersity of less than 5%.

[0042] (2) Preparation of the second polymer core dispersed with fluorescent dyes: Take 4.0 g of the prepared first polymer core, 20 mL of purified water, and 0.8 g of acrylic acid Pluronic F127 into a 50 mL sin...

Embodiment 4

[0044] Example 4: (1) Preparation of the first polymer core: take 100mL of purified water, mix 10 grams of rectified methacrylate, 1.5 grams of sodium lauryl sulfate and 0.26 grams of AIBA (azobisisobutyl Add amidine hydrochloride) into a 250mL three-necked flask equipped with a stirrer, thermometer and condenser, ultrasonically disperse for 10 minutes, stir for 1 hour under nitrogen protection, set the stirring rate at 450r / min, and then slowly raise the temperature to 70°C , continue the reaction for 12 hours, lower the temperature to room temperature, stop stirring, remove the nitrogen, centrifuge the product and wash it fully with methanol, freeze-dry, and obtain the first polymer core with a particle size of 240nm, and the monodispersity is lower than 5%.

[0045] (2) Preparation of the second polymer core with fluorescent dye dispersed: take 2 grams of the prepared first polymer core, 20 mL of purified water, and 0.8 g of maleic anhydride-acrylic acid copolymer into a 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

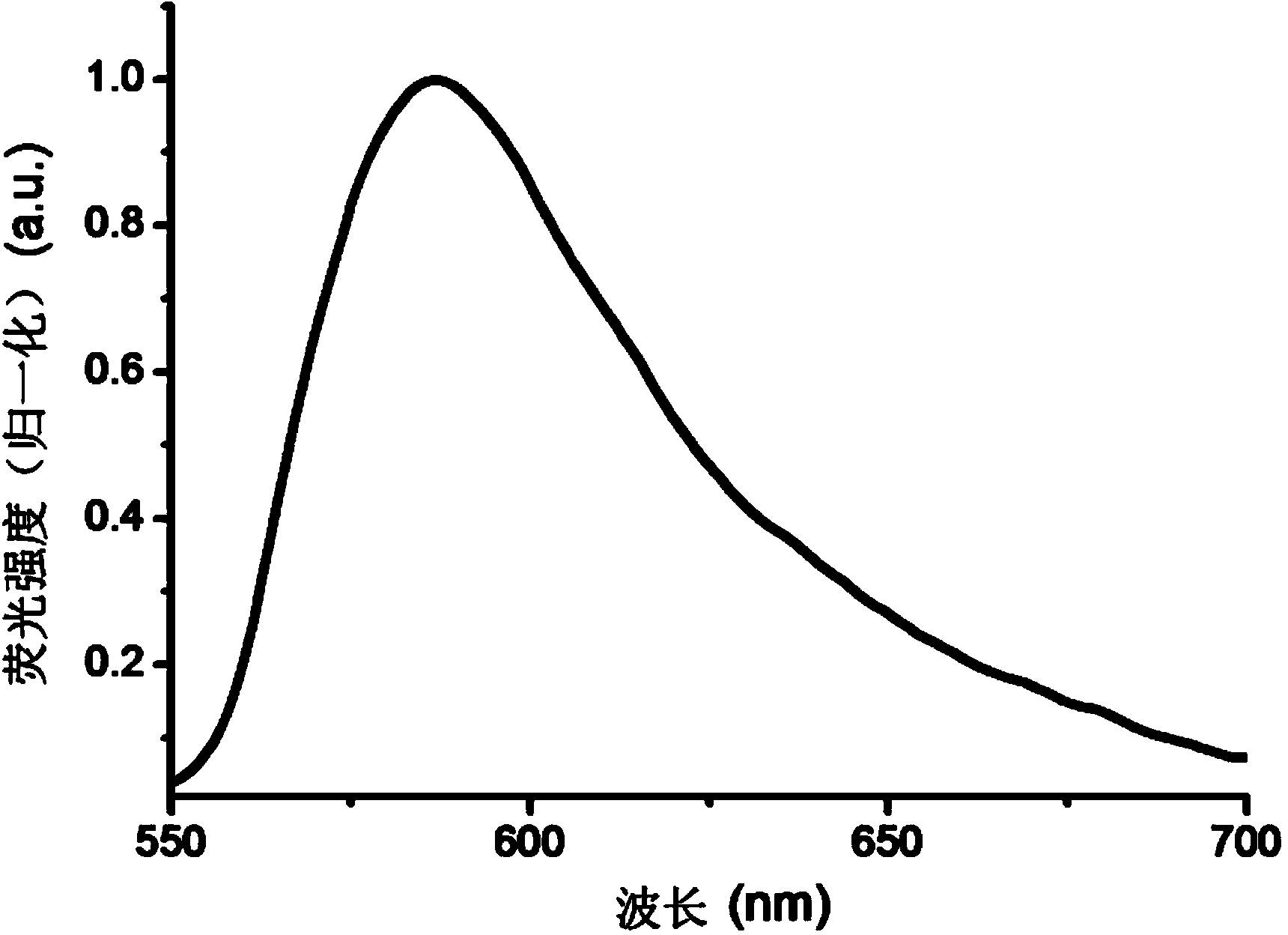

| Luminescence spectrum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com