Ultraviolet double-wave excitation fluorescent transparent invisible anti-fake nano-paper preparation method

A nano-paper and fluorescence technology, which is used in replication/marking methods, papermaking, textiles and papermaking, etc., can solve the problems of poor anti-counterfeiting ability, easy overlapping of emission spectra, and difficult identification of fluorescent labels, and achieves reduction of light scattering, excitation and Long launch period and strong double anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] S1. Uniformly disperse ONFC in 100 mL ethanol solution to form a stable suspension of 0.5w / v%, then add 5 mg Tb(Tfacac) to the solution 3 (H 2 O) 2 , ultrasonically disperse evenly, then pour the obtained suspension into a high-pressure filter press, adjust the appropriate pressure, and press-filter until the filtrate no longer flows out to obtain transparent nano-paper.

[0019] S2. Disperse fluorescent carbon dots with a particle size of about 4 nm in deionized water at a ratio of 0.05 mg / mL as fluorescent ink, and use screen printing technology to print the two-dimensional code of the product on the surface of fluorescent transparent nanopaper. Place it on a flat glass sheet to dry naturally to obtain an invisible double-fluorescence transparent nano-paper with a two-dimensional code.

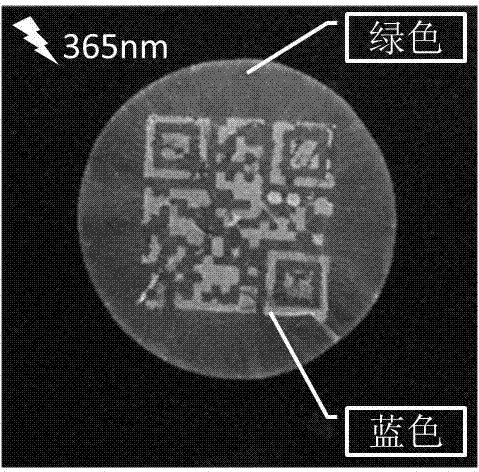

[0020] S3. Fluorescent performance test: Under the excitation of ultraviolet light with a wavelength of 365 nm, the carbon quantum dots will emit blue fluorescence, and a clear blue...

Embodiment 2

[0022] S1. Disperse ONFC evenly in 100 mL ethanol solution to form a stable suspension of 0.5w / v%, then add 5 mg Eu(dbm) to the solution 3 (H 2 O) 2 , ultrasonically disperse evenly, then pour the obtained suspension into a high-pressure filter press, adjust the appropriate pressure, and press-filter until the filtrate no longer flows out to obtain transparent nano-paper.

[0023] S2. Disperse fluorescent carbon dots with a particle size of about 4 nm in anhydrous ethanol at a ratio of 0.1 mg / mL as fluorescent ink, and use screen printing technology to print the two-dimensional code of the product on the surface of fluorescent transparent nano-paper. It is placed on a flat glass sheet to dry naturally, and an invisible double fluorescent transparent nano-paper with a two-dimensional code is obtained.

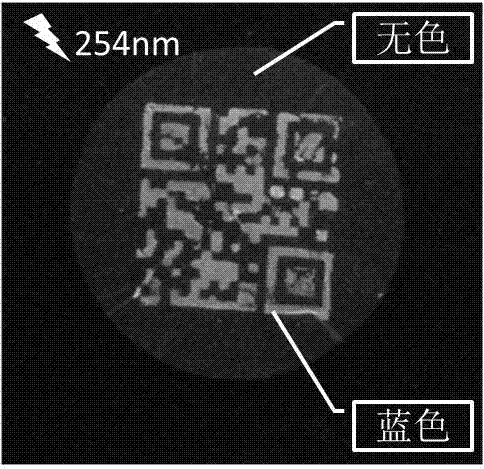

[0024] S3. Fluorescence performance test: Under the excitation of ultraviolet light with a wavelength of 254 nm, the carbon quantum dots will emit blue fluorescence, and a cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com