Method for refining electrodeposited nickel crystal grains through cerium trichloride

A cerium trichloride and electrodeposited nickel technology, which is applied in the field of electrodeposited nickel, can solve the problems of refining electrodeposited nickel crystal grains without cerium trichloride, and achieves remarkable effect of refining crystal grains, low cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

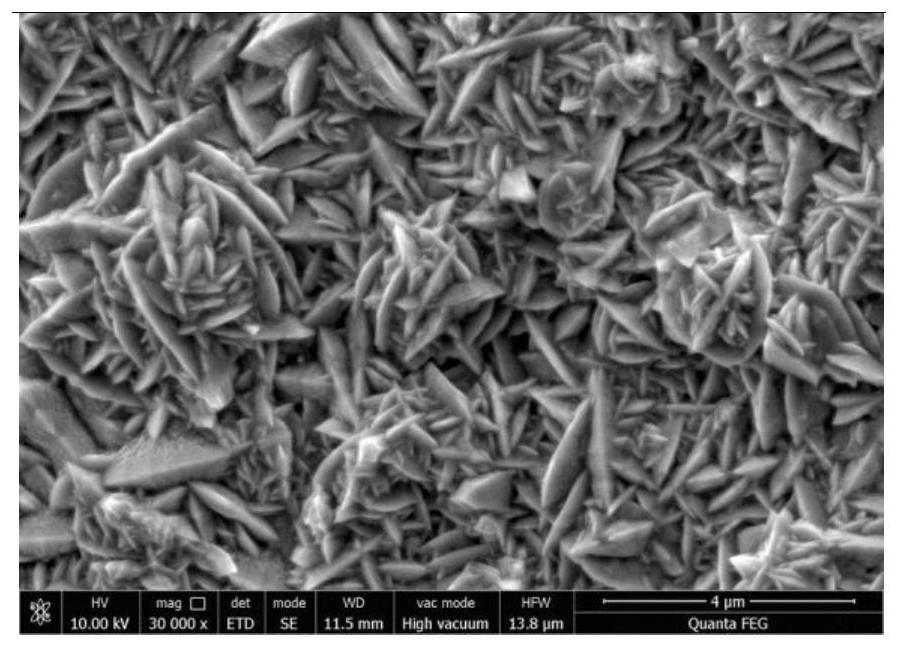

Embodiment 1

[0038] A method utilizing cerium trichloride to refine electrodeposited nickel grains, the steps are as follows:

[0039] S1. Preparation of deposition solution: adding cerium trichloride to the electrolyte, stirring and dissolving to obtain a deposition solution;

[0040] S2. Cathode test piece treatment: stripping the polished surface of the cathode test piece, ultrasonic cleaning, rinsing, activating, rinsing, and drying to obtain the treated cathode test piece;

[0041] S3. Electrodeposition: adding the deposition solution to the electrodeposition tank, heating, putting in the cathode test piece and the anode test piece, connecting the power supply, electrifying and performing electrodeposition, and obtaining the cathode test piece after electrodeposition;

[0042] S4. Post-treatment of the cathode test piece: rinse, dry and seal the electrodeposited cathode test piece to obtain a nickel-plated cathode test piece.

[0043] In step S1, the electrolyte solution includes the...

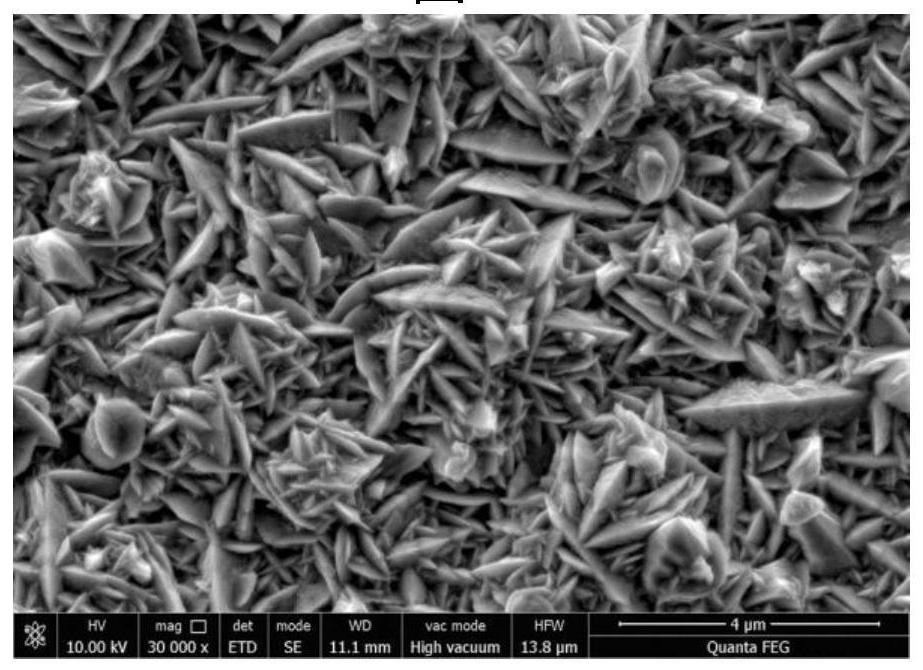

Embodiment 2

[0053] A method utilizing cerium trichloride to refine electrodeposited nickel grains, the steps are as follows:

[0054] S1. Preparation of deposition solution: adding cerium trichloride to the electrolyte, stirring and dissolving to obtain a deposition solution;

[0055] S2. Cathode test piece treatment: stripping the polished surface of the cathode test piece, ultrasonic cleaning, rinsing, activating, rinsing, and drying to obtain the treated cathode test piece;

[0056] S3. Electrodeposition: adding the deposition solution to the electrodeposition tank, heating, putting in the cathode test piece and the anode test piece, connecting the power supply, electrifying and performing electrodeposition, and obtaining the cathode test piece after electrodeposition;

[0057] S4. Post-treatment of the cathode test piece: rinse, dry and seal the electrodeposited cathode test piece to obtain a nickel-plated cathode test piece.

[0058] In step S1, the electrolyte solution includes the...

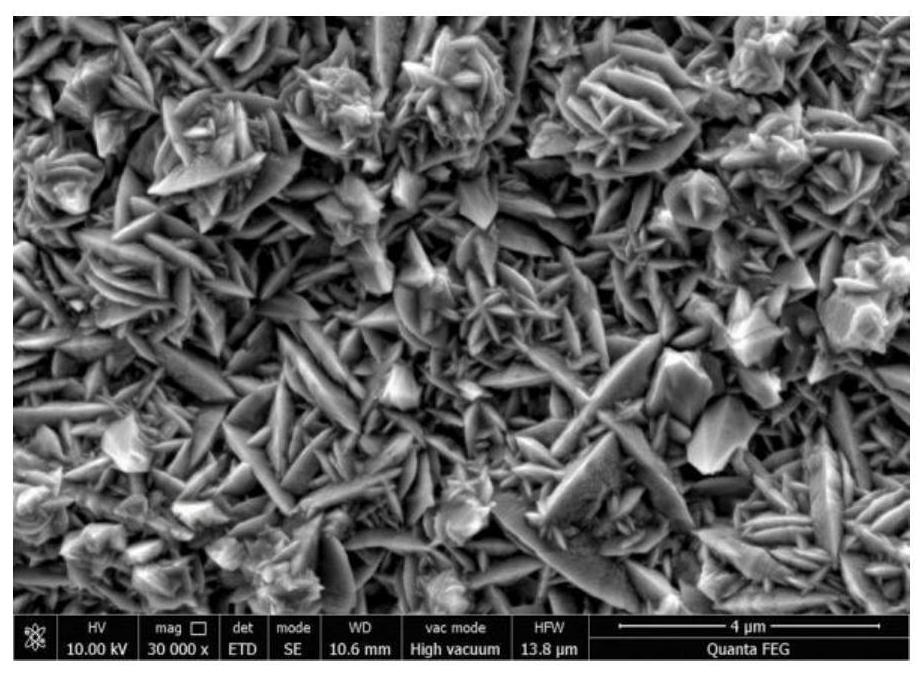

Embodiment 3

[0068] A method utilizing cerium trichloride to refine electrodeposited nickel grains, the steps are as follows:

[0069] S1. Preparation of deposition solution: adding cerium trichloride to the electrolyte, stirring and dissolving to obtain a deposition solution;

[0070] S2. Cathode test piece treatment: stripping the polished surface of the cathode test piece, ultrasonic cleaning, rinsing, activating, rinsing, and drying to obtain the treated cathode test piece;

[0071] S3. Electrodeposition: adding the deposition solution to the electrodeposition tank, heating, putting in the cathode test piece and the anode test piece, connecting the power supply, energizing for electrodeposition, and obtaining the cathode test piece after electrodeposition;

[0072] S4. Post-treatment of the cathode test piece: rinse, dry and seal the electrodeposited cathode test piece to obtain a nickel-plated cathode test piece.

[0073] In step S1, the electrolyte solution includes the following co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com