Anti-counterfeiting ink for plastic packaging

A technology for anti-counterfeiting ink and plastic packaging, applied in the field of ink, can solve the problems of no enhanced fluorescence intensity, short service life, poor oxidation resistance, etc., and achieve the effects of prolonging the fluorescence decay time, improving the service life and improving the oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

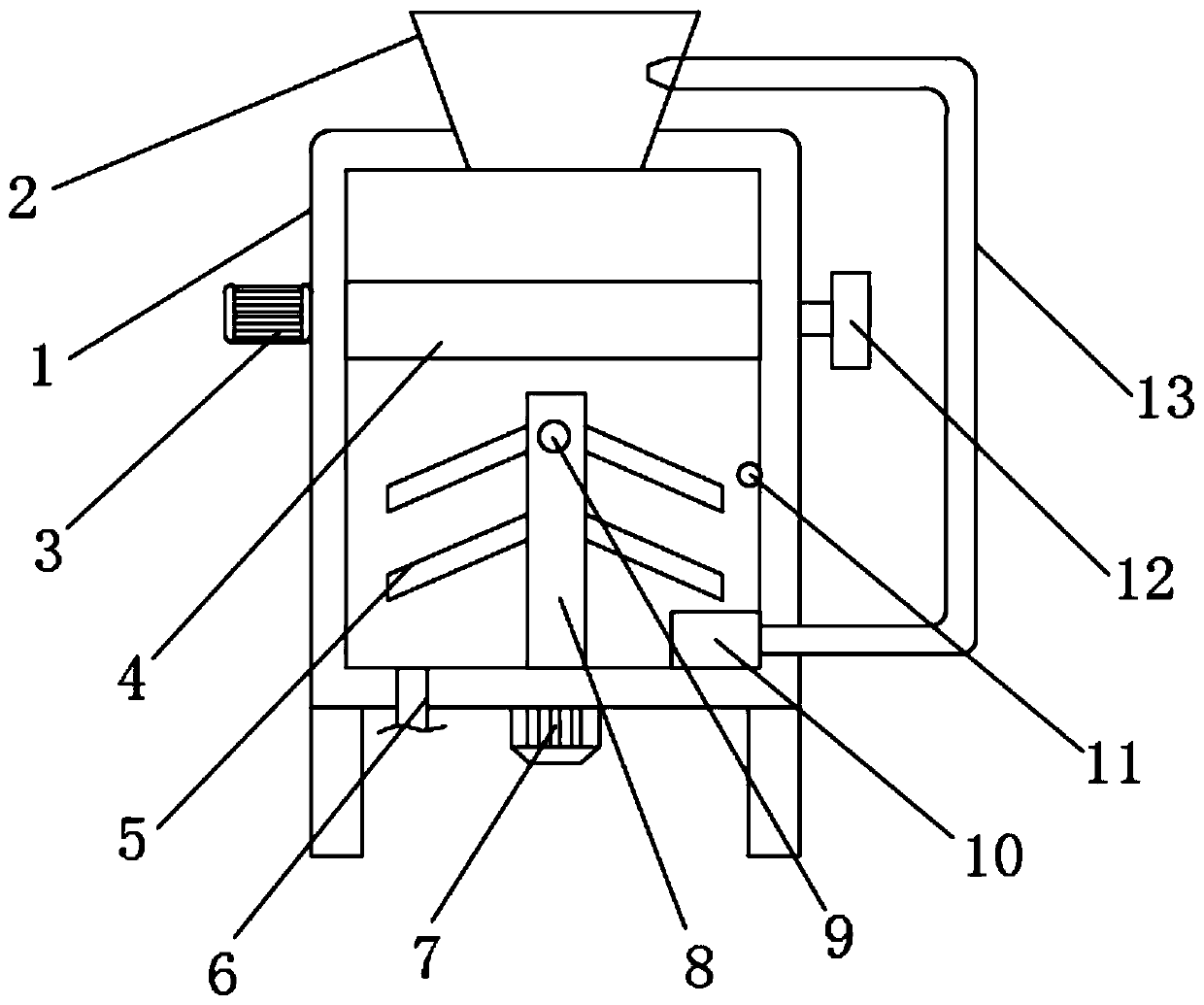

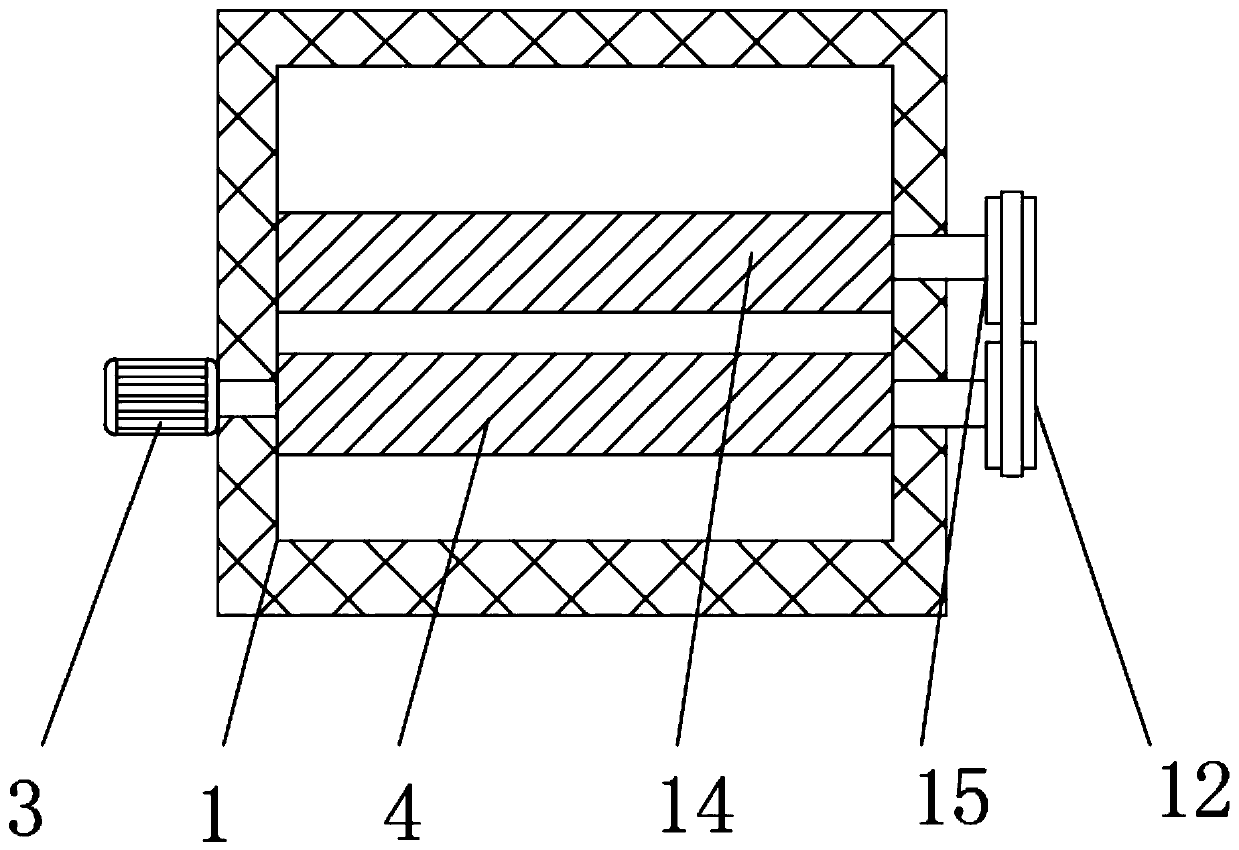

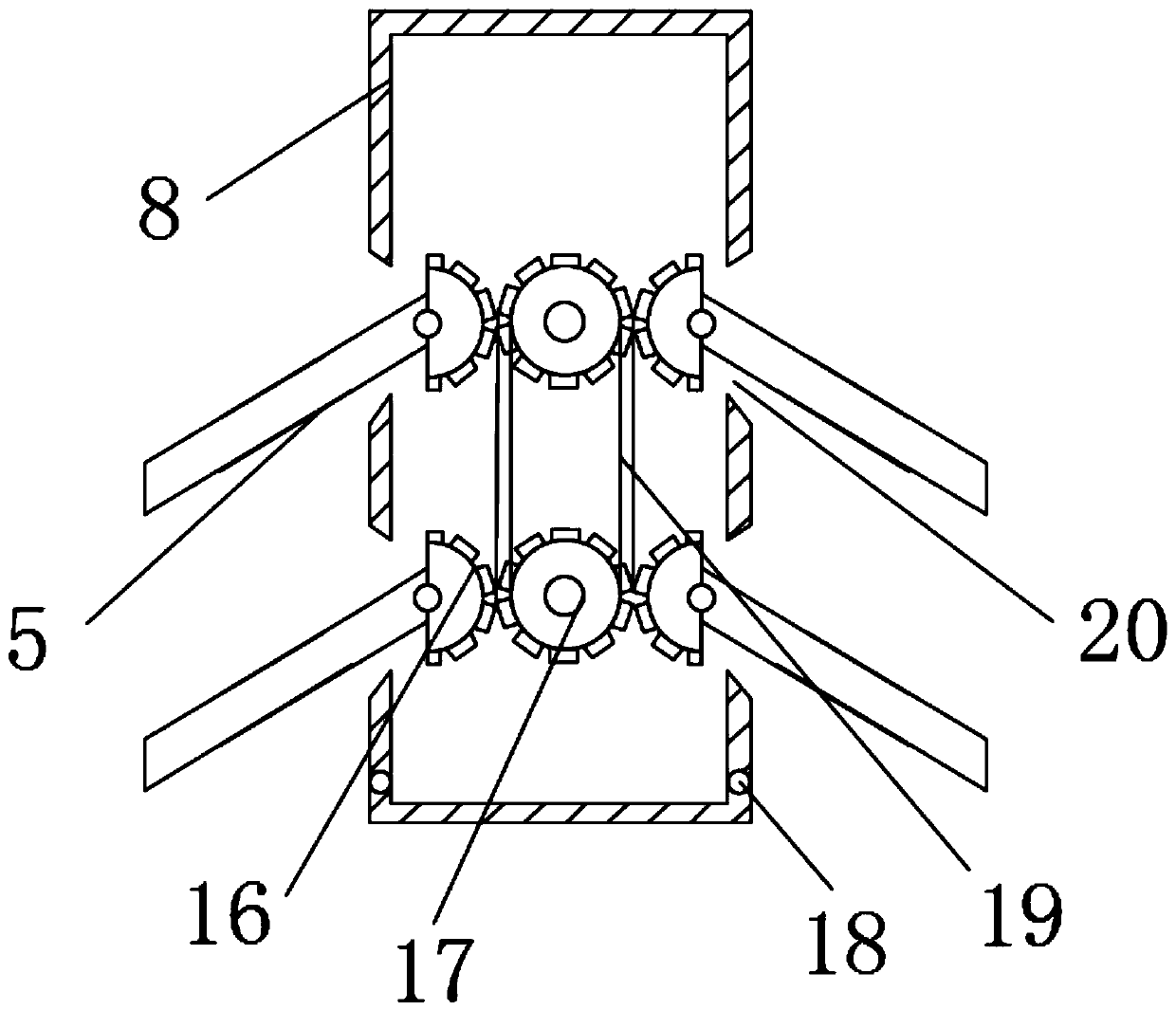

[0036] see Figure 1-3 Shown, a kind of anti-counterfeit ink for plastic packaging, this anti-counterfeit ink is prepared by following raw materials by weight: 120 parts of resin, 0.3 part of fluorescent powder, 12 parts of cerium trichloride, 24 parts of lanthanum trichloride, 36 parts of chitosan Sugar, 12 parts of pigments, 2 parts of additives;

[0037] The anti-counterfeiting ink is prepared through the following steps:

[0038] Step 1, react cerium trioxide and hydrochloric acid in a container, the reaction temperature is 85 ° C, and the reaction time is 30 minutes to obtain an aqueous solution of cerium trichloride, which is filtered and dried to obtain solid cerium trichloride. Prepare solid lanthanum trichloride under the method;

[0039] Step 2: Dissolve the prepared lanthanum trichloride and cerium trichloride with distilled water, move to the volumetric flask of 100mL respectively, dilute to obtain 1mol / L lanthanum trichloride and cerium trichloride solution, the p...

Embodiment 2

[0046] see Figure 1-3 Shown, a kind of anti-counterfeiting ink for plastic packaging, this anti-counterfeiting ink is prepared by the following raw materials in parts by weight: 80 parts of resin, 0.2 part of fluorescent powder, 8 parts of cerium trichloride, 16 parts of lanthanum trichloride, 24 parts of chitosan Sugar, 8 parts of pigment, 1 part of additive;

[0047] The anti-counterfeiting ink is prepared through the following steps:

[0048] Step 1, react cerium trioxide and hydrochloric acid in a container, the reaction temperature is 75 ° C, and the reaction time is 3 minutes to obtain an aqueous solution of cerium trichloride, which is filtered and dried to obtain solid cerium trichloride. Prepare solid lanthanum trichloride under the method;

[0049] Step 2: Dissolve the prepared lanthanum trichloride and cerium trichloride with distilled water, move to the volumetric flask of 100mL respectively, dilute to obtain 1mol / L lanthanum trichloride and cerium trichloride s...

Embodiment 3

[0055] see Figure 1-3 Shown, a kind of anti-counterfeiting ink for plastic packaging, this anti-counterfeiting ink is prepared by following raw materials in parts by weight: 80 parts of resin, 0.2 part of fluorescent powder, 8 parts of cerium trichloride, 24 parts of chitosan, 8 parts of pigment, 1 part of auxiliary agent;

[0056] The anti-counterfeiting ink is prepared through the following steps:

[0057] Step 1, reacting cerium trioxide and hydrochloric acid in a container, the reaction temperature is 75° C., and the reaction time is 3 minutes to obtain an aqueous solution of cerium trichloride, which is filtered and dried to obtain solid cerium trichloride;

[0058] Step 2, dissolve the prepared cerium trichloride with distilled water, move to 100mL volumetric flask respectively, dilute to obtain 1mol / L cerium trichloride solution, the pH value of the solution is 5.5;

[0059] Step 3. Add the cerium trichloride solution prepared in step 2 dropwise to excess chitosan di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com