Preparation method of manganese dioxide composite material

A composite material, manganese dioxide technology, applied in chemical instruments and methods, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the methanol conversion rate and formaldehyde yield reaction effect is ideal, improve production The problems of high cost and catalyst dosage can achieve the effect of easy and rapid mass preparation, short reaction period and improved treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

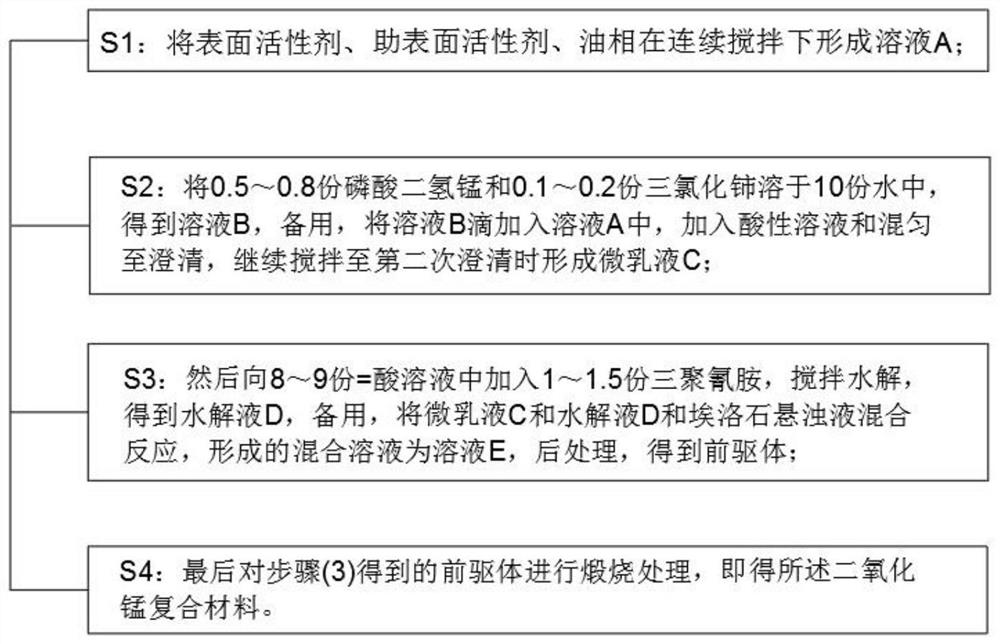

[0038] refer to figure 1 , a preparation method of manganese dioxide composite material, specifically comprises the following steps:

[0039]S1: The surfactant, cosurfactant and oil phase are formed into solution A under continuous stirring;

[0040] S2: Dissolve 0.5-0.8 parts of manganese dihydrogen phosphate and 0.1-0.2 parts of cerium trichloride in 10 parts of water to obtain solution B, which is used for later use. Add solution B dropwise to solution A, add acid solution and mix until it becomes clear, Continue to stir to form microemulsion C during the second clarification;

[0041] S3: then add 1~1.5 parts of melamine to 8~9 parts=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com