Surface treatment process for valve body casting part

A technology of surface treatment and casting, which is applied in the field of surface treatment of valve body castings. It can solve problems such as corrosion resistance to be improved, ball valve failure, and difficulty in forming a sealed state, and achieve the effect of improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

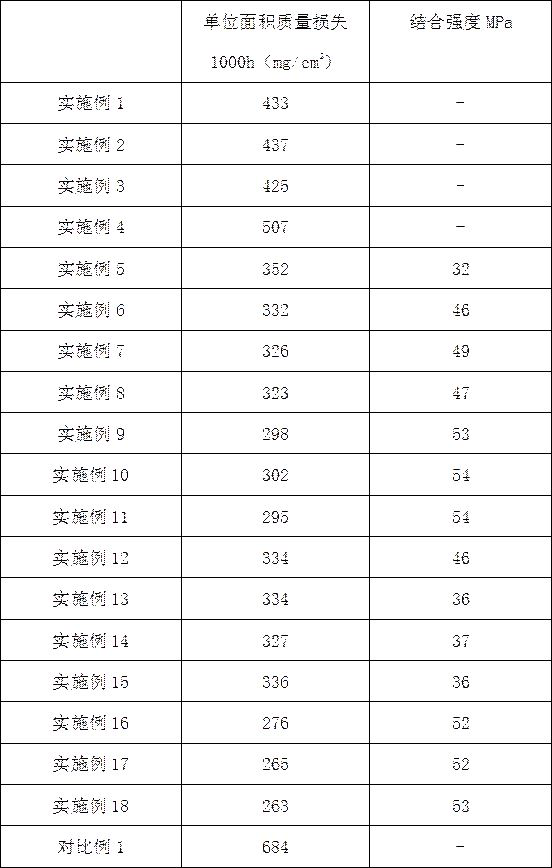

Examples

Embodiment 1

[0039] A surface treatment process for a valve body casting, characterized in that it comprises the following steps:

[0040] S1, pretreatment of valve body castings: the cast valve body castings are sequentially washed with water, 10wt% hydrochloric acid pickling, water washed, and dried to obtain the pretreated valve body castings;

[0041] S2, the first surface treatment of the valve body casting: soak the pretreated valve body casting in the treatment agent for 5 minutes, remove and dry, and obtain the valve body casting after the first surface treatment.

[0042] The preparation method of treatment agent is as follows:

[0043] S1, pretreatment: Dissolve bis(dimercapto-1,3,4-thiadiazole) in acetone solution, filter with suction, evaporate the obtained filtrate to dryness under reduced pressure, dissolve it in 95wt% ethanol and recrystallize to remove acetone, Obtain pretreated bis(dimercapto-1,3,4-thiadiazole);

[0044] S2, in parts by weight, dissolve 4 parts of bis(di...

Embodiment 2

[0046] A surface treatment process for a valve body casting, characterized in that it comprises the following steps:

[0047]S1, pretreatment of valve body castings: the cast valve body castings are sequentially washed with water, washed with 10wt% hydrochloric acid, washed with water, and dried to obtain the pretreated valve body castings;

[0048] S2, the first surface treatment of the valve body casting: soak the pretreated valve body casting in the treatment agent for 5 minutes, remove and dry, and obtain the valve body casting after the first surface treatment.

[0049] The preparation method of treatment agent is as follows:

[0050] S1, pretreatment: Dissolve bis(dimercapto-1,3,4-thiadiazole) in acetone solution, filter with suction, evaporate the obtained filtrate to dryness under reduced pressure, dissolve it in 95wt% ethanol and recrystallize to remove acetone, Obtain pretreated bis(dimercapto-1,3,4-thiadiazole);

[0051] S2, in parts by weight, dissolve 6 parts of...

Embodiment 3

[0053] A surface treatment process for a valve body casting, characterized in that it comprises the following steps:

[0054] S1, pretreatment of valve body castings: the cast valve body castings are sequentially washed with water, washed with 10wt% hydrochloric acid, washed with water, and dried to obtain the pretreated valve body castings;

[0055] S2, the first surface treatment of the valve body casting: soak the pretreated valve body casting in the treatment agent for 5 minutes, remove and dry, and obtain the valve body casting after the first surface treatment.

[0056] The preparation method of treatment agent is as follows:

[0057] S1, pretreatment: Dissolve bis(dimercapto-1,3,4-thiadiazole) in acetone solution, filter with suction, evaporate the obtained filtrate to dryness under reduced pressure, dissolve it in 95wt% ethanol and recrystallize to remove acetone, Obtain pretreated bis(dimercapto-1,3,4-thiadiazole);

[0058] S2, in parts by weight, dissolve 5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com