Manganese dioxide composite material and preparation method and application thereof

A composite material, manganese dioxide technology, applied in the preparation of carbon-based compounds, organic compounds, carbonyl compounds by oxidation, etc., can solve the problem of ideal methanol conversion and formaldehyde yield, high catalyst consumption, and high production costs and other problems, to achieve the effect of promoting the conversion rate of methanol and the yield of formaldehyde, good adsorption, and improved adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

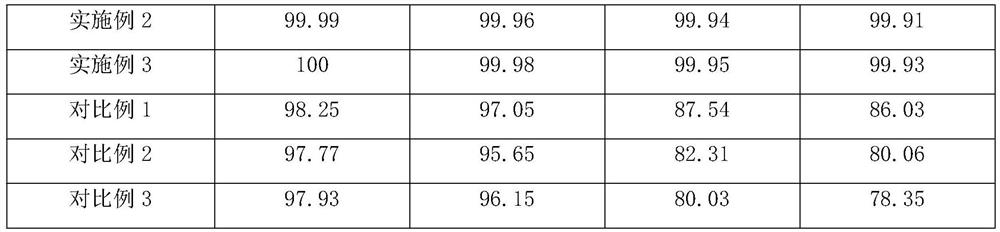

Embodiment 1

[0040] A kind of preparation method of manganese dioxide composite material, concrete steps are as follows:

[0041] (1) 0.5g manganese dihydrogen phosphate and 0.2g cerium trichloride are dissolved in 10g water earlier to obtain an aqueous solution;

[0042] (2) Then add 1 g of melamine to 8 g of acid solution with pH=4.5, stir and hydrolyze to obtain a hydrolyzate;

[0043] (3) Then the aqueous solution, the hydrolyzate and the halloysite suspension are mixed and reacted, and post-treated to obtain the precursor;

[0044] (4) Finally, the precursor is calcined to obtain the manganese dioxide composite material;

[0045] Wherein, the halloysite suspension is obtained by first depositing 0.5 g of nanometer zirconia on the surface of 8 g of halloysite, and then uniformly dispersing it with 70 g of 0.5 mol / L sodium hydroxide solution.

[0046] Wherein, in step (2), the acid solution is hydrochloric acid.

[0047] In step (2), the process condition of stirring hydrolysis is: s...

Embodiment 2

[0060] A kind of preparation method of manganese dioxide composite material, concrete steps are as follows:

[0061] (1) 0.8g manganese dihydrogen phosphate and 0.1g cerium trichloride are dissolved in 10g water earlier to obtain an aqueous solution;

[0062] (2) Then add 1.5 g of melamine to 9 g of acid solution with pH=3.5, stir and hydrolyze to obtain a hydrolyzate;

[0063] (3) Then the aqueous solution, the hydrolyzate and the halloysite suspension are mixed and reacted, and post-treated to obtain the precursor;

[0064] (4) Finally, the precursor is calcined to obtain the manganese dioxide composite material;

[0065] Wherein, the halloysite suspension is obtained by first depositing 0.8 g of nanometer zirconia on the surface of 5 g of halloysite, and then uniformly dispersing it with 60 g of 1mol / L sodium hydroxide solution.

[0066] In step (2), the acid solution is sulfuric acid.

[0067] In step (2), the process condition of stirring hydrolysis is: stirring at 35°...

Embodiment 3

[0080] A kind of preparation method of manganese dioxide composite material, concrete steps are as follows:

[0081] (1) Dissolve 0.7g manganese dihydrogen phosphate and 0.15g cerium trichloride in 10g water earlier to obtain an aqueous solution;

[0082] (2) Then add 1.2 g of melamine to 8.5 g of acid solution with pH=4, stir and hydrolyze to obtain a hydrolyzate;

[0083] (3) Then the aqueous solution, the hydrolyzate and the halloysite suspension are mixed and reacted, and post-treated to obtain the precursor;

[0084] (4) Finally, the precursor is calcined to obtain the manganese dioxide composite material;

[0085] Wherein, the halloysite suspension is obtained by first depositing 0.6 g of nanometer zirconia on the surface of 7 g of halloysite, and then uniformly dispersing it with 65 g of 0.8 mol / L sodium hydroxide solution.

[0086] In step (2), the acid solution is hydrochloric acid, sulfuric acid or nitric acid solution.

[0087] In step (2), the process condition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com