A preparation method of ceria nanorod doped titania nanoparticle photocatalyst

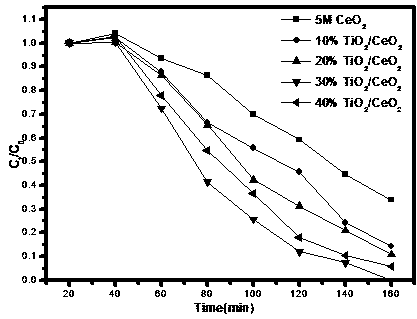

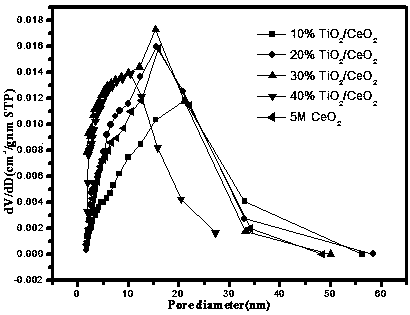

A ceria, photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of spinning system and preparation conditions, etc., Achieve the effect of high utilization rate, strong degradation effect and strong photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of ceria nanorod doped titania nanoparticle photocatalyst, the steps are as follows:

[0026] Synthesis of ceria nanorods:

[0027] 1.5g CeCl 3 •7H 2 O was dissolved in 5ml deionized water to make liquid A, 2.4g NaOH was dissolved in 15ml deionized water to make liquid B, mixed liquid A and liquid B, stirred for 10min, then added the mixed solution into the reaction kettle, and reacted React at 130°C for 18 hours, wash the product with deionized water, then react and dry at room temperature for 20 hours, and continue to bake at 300°C for 4 hours to prepare ceria nanorods;

[0028] Synthetic CeO 2 / TiO 2 catalyst of light:

[0029] Put 100mg of ceria nanorods prepared in step (1) into 50-100ml of water and stir, then add 0.095ml of TiCl 3 solution, stir the mixture for 30 minutes, put it in a reaction kettle, and react at 180°C for 12 hours. After the reaction is completed, the product is washed repeatedly with deionized water and ethanol, ...

Embodiment 3

[0031] A preparation method of ceria nanorod doped titania nanoparticle photocatalyst, the steps are as follows:

[0032] Synthesis of ceria nanorods:

[0033] With embodiment 1.

[0034] Synthetic CeO 2 / TiO 2 catalyst of light:

[0035] Put 100mg of ceria nanorods prepared in step (1) into 50-100ml of water and stir, then add 0.19ml of TiCl 3 solution, stir the mixture for 30 minutes, put it in a reaction kettle, and react at 180°C for 12 hours. After the reaction is completed, the product is washed repeatedly with deionized water and ethanol, and then dried in a vacuum drying oven at 60°C to obtain ceria Nanorod-doped titania particle photocatalyst, namely 20% CeO 2 / TiO 2 Nanocomposite, the mass of titanium dioxide accounts for 20% of the mass of ceria.

Embodiment 4

[0037] A preparation method of ceria nanorod doped titania nanoparticle photocatalyst, the steps are as follows:

[0038] Synthesis of ceria nanorods:

[0039] With embodiment 1.

[0040] Synthetic CeO 2 / TiO 2 catalyst of light:

[0041] Put 100mg of ceria nanorods prepared in step (1) into 50-100ml of water and stir, then add 0.285ml of TiCl 3 solution, stir the mixture for 30 minutes, put it in a reaction kettle, and react at 180°C for 12 hours. After the reaction is completed, the product is washed repeatedly with deionized water and ethanol, and then dried in a vacuum drying oven at 60°C to obtain ceria Nanorod-doped titania particle photocatalyst, namely 30% CeO 2 / TiO 2 Nanocomposite, the mass of titanium dioxide accounts for 30% of the mass of ceria.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com