High-leveling performance acid copper brightener for copper electroplating

A technology for filling acid copper and electroplating copper, which is applied in the field of high leveling acid copper brighteners for electroplating copper, which can solve the problems of poor dispersion of brighteners, pollute the environment, increase costs, etc., improve the properties of the coating, and increase the cathode polarization function, the effect of reducing the overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

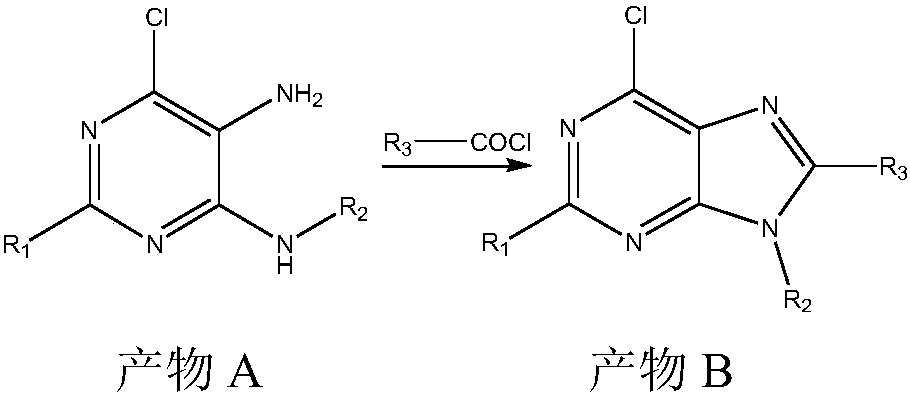

[0065] The preparation method of described leveling agent B at least comprises the following steps:

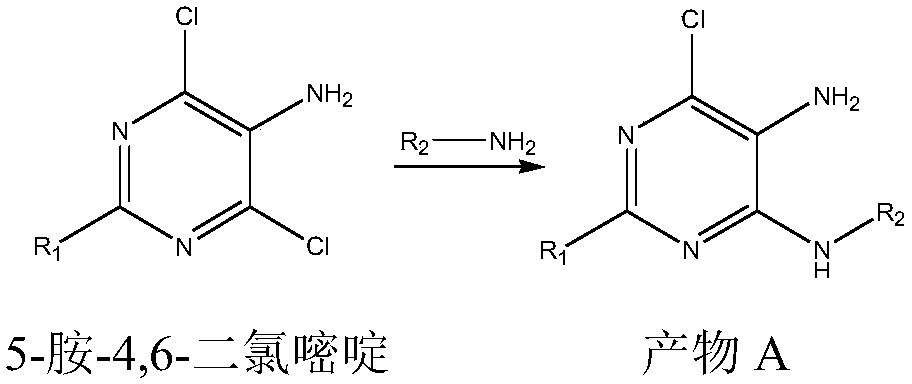

[0066] a. Take 5-amine-4,6-dichloropyrimidine, R 2 -NH 2 and triethylamine, where 5-amine-4,6-dichloropyrimidine, R 2 -NH 2 The molar ratio of triethylamine and triethylamine is 1:2:2, add solvent n-butanol, the molar ratio of n-butanol and 5-amine-4,6-dichloropyrimidine is 45:1, stir, heat to reflux, collect after 6h Product A, the reaction equation is shown below.

[0067]

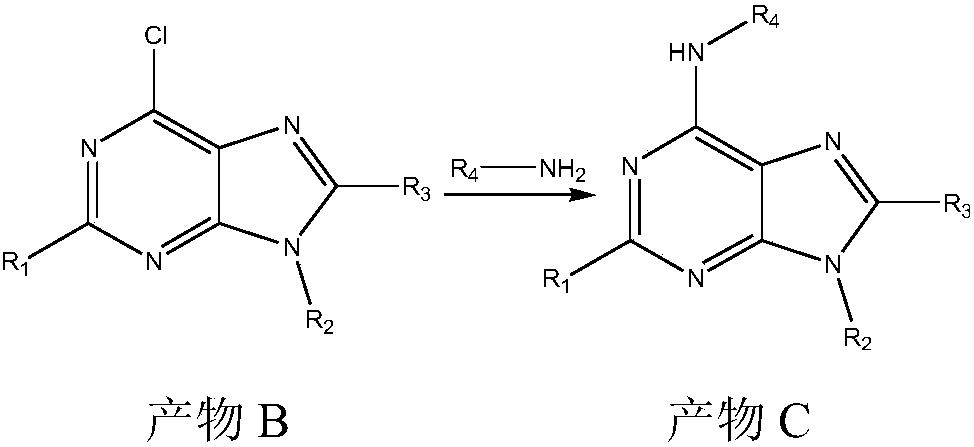

[0068] b. Take products A and R 3 -COCl and polyphosphoric acid are dissolved in phosphorus oxychloride, wherein the products A and R 3 The molar ratio of -COCl, polyphosphoric acid and phosphorus oxychloride is 2:3:3:20. The reaction is carried out under the protection of nitrogen, stirred, heated to reflux, and the product B is collected after 12 hours. The reaction equation is shown below.

[0069]

[0070] c. Dissolve product B in dichloromethane, the molar ratio of product B to dichlorom...

Embodiment 1

[0111] Embodiment 1 provides a kind of high-filling acid copper brightener for electroplating copper, and the high-filling acid copper brightener for electroplating copper described in 1L is made up of the raw material of following mass proportion:

[0112] Leveling agent: 3g;

[0113] Accelerator: 1.5g;

[0114] Carrier: 7g;

[0115] Water was added to 1L.

[0116] The leveling agent is a mixture of leveling agent A and leveling agent B, and the mass ratio of leveling agent A and leveling agent B is 2:1. Leveling agent A is GISS (purchased from Jiangsu Mengde New Material Technology Co., Ltd.), and leveling agent B is made of monomer Aggregation is obtained, where R 1 , R 2 , R 4 Respectively H, methyl, n-butyl; R 3 For propenyl. The accelerator is ethylene thiourea and 1,3-dithioglycerol, and the molar ratio of ethylene thiourea and 1,3-dithioglycerol is 1:1. The carrier is PEG 4000.

[0117] The preparation method of described leveling agent B at least comprises ...

Embodiment 2

[0127] Embodiment 2 provides a kind of high leveling acid copper brightener for electroplating copper, 1L described copper electroplating uses high leveling acid copper brightener to be made up of the raw material of following mass proportion:

[0128] Leveling agent: 4g;

[0129] Accelerator: 2.5g;

[0130] Carrier: 15g;

[0131] Water was added to 1L.

[0132] The leveling agent is a mixture of leveling agent A and leveling agent B, and the mass ratio of leveling agent A and leveling agent B is 2:1. Leveling agent A is PVP K15 of Guangzhou Yuemei Chemical Co., Ltd., and leveling agent B is made of monomer Aggregation is obtained, where R 1 , R 2 , R 4 Respectively H, benzyl, methyl; R 3 For propenyl. The accelerator is ethylene thiourea and 1,3-dithioglycerol, and the molar ratio of ethylene thiourea and 1,3-dithioglycerol is 1:1. The carrier is PEG 4000.

[0133] The preparation method of leveling agent B is the same as embodiment 1, wherein R 1 , R 2 , R 4 Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com