Safe and environment-friendly additive for copper plating, and preparation method of additive

A safe, environmentally friendly, additive technology, applied in the field of electroplating, can solve the problems of reducing the bonding force of the coating, cannot be directly electroplated, and has low solubility in water, etc., and achieves the effects of low cost, improved brightness, and slowed down precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

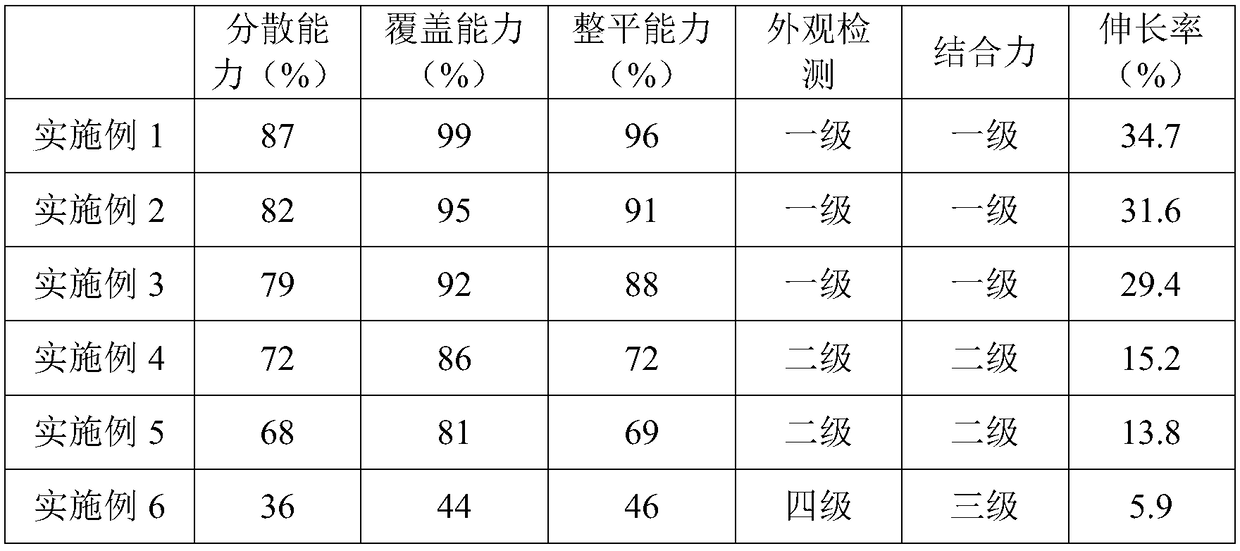

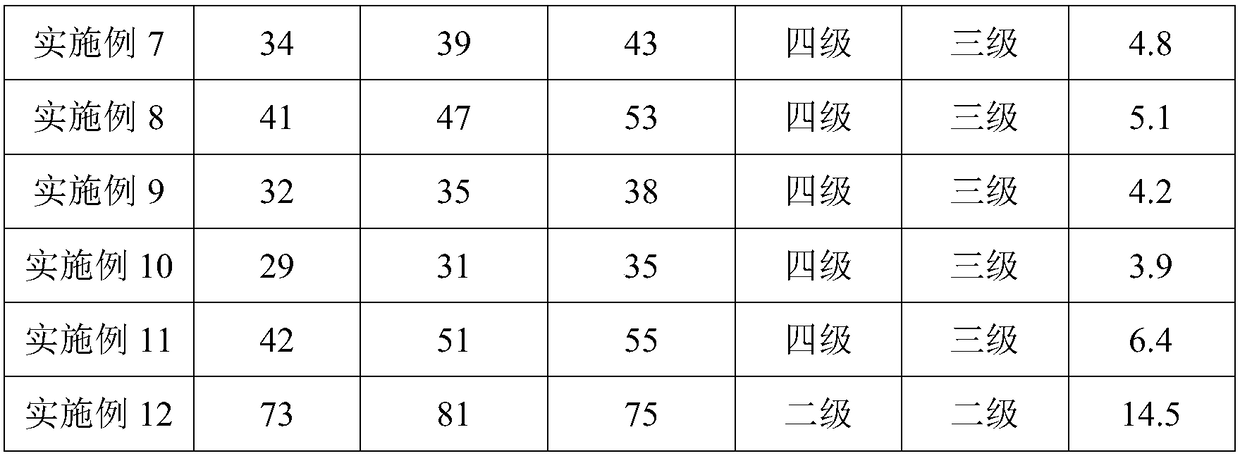

Examples

Embodiment 1

[0070] Embodiment 1 of the present invention provides a safe and environment-friendly copper plating additive, including 5g / L aliphatic amine polyoxyethylene ether, 3g / L mercapto-containing heterocyclic compound, 13g / L polyethyleneimine alkyl compound and 1.5g / L L complexing agent;

[0071] The total amine value of the fatty amine polyoxyethylene ether is 55KOH / g, and the structure is R 1 It is a hydrocarbon group with 12 carbon atoms, n=2, m=4;

[0072] Determination of total amine value:

[0073] Instruments required for determination: Erlenmeyer flask, acid burette (25mL), analytical balance;

[0074] Reagents required for determination: glacial acetic acid, pure benzene, perchloric acid and methyl violet;

[0075] The methyl violet indicator solution that needs to be configured for the determination: 0.1% methyl violet glacial acetic acid solution;

[0076] Determination steps:

[0077] (1) Accurately weigh 0.2g sample, place it in a conical flask, add 25mL glacial ...

Embodiment 2

[0092] Example 2 of the present invention provides a safe and environment-friendly copper plating additive, the specific implementation of which is the same as in Example 1, except that it includes 8g / L fatty amine polyoxyethylene ether, 5g / L mercapto-containing heterocyclic compound, 20g / L polyethyleneimine alkyl compound and 3g / L complexing agent;

[0093] The 5-oxo-6-(mercaptomethyl)-1-thia-4-azacyclotridecane-3-carboxylic acid and 5-mercapto-4-phenyl-3H-1,2-di The weight ratio of thiolene-3-thione is 3:1;

[0094] The molar ratio of the polyethyleneimine to the halogen-containing cyclic compound is 2:1;

[0095] The weight ratio of disodium edetate to triethanolamine is 5:1.

Embodiment 3

[0097] Example 3 of the present invention provides a safe and environment-friendly copper plating additive, the specific implementation of which is the same as that of Example 1, except that it includes 2g / L aliphatic amine polyoxyethylene ether, 1g / L mercapto-containing heterocyclic compound, 5g / L polyethyleneimine alkyl compound and 0.5g / L complexing agent;

[0098] The 5-oxo-6-(mercaptomethyl)-1-thia-4-azacyclotridecane-3-carboxylic acid and 5-mercapto-4-phenyl-3H-1,2-di The weight ratio of thiolene-3-thione is 0.5:1;

[0099] The molar ratio of the polyethyleneimine to the halogen-containing cyclic compound is 0.2:1;

[0100] The weight ratio of disodium edetate to triethanolamine is 0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com