Electroplating liquid for nickel-cadmium battery negative pole and manufacturing method for nickel-cadmium battery negative pole

A nickel-cadmium battery and a manufacturing method technology, applied in the direction of alkaline storage battery electrodes, etc., can solve the problem of serious exothermic reaction of the negative electrode, and achieve the effects of good fast charging capability, fine and bright coating, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Positive electrode production:

[0028] Manufactured by conventional technology: length: 63±2mm, width: 39±0.5mm, thickness: 0.65±0.035mm nickel positive plate, the dry weight of the active material mixture is about 3.5-3.6g.

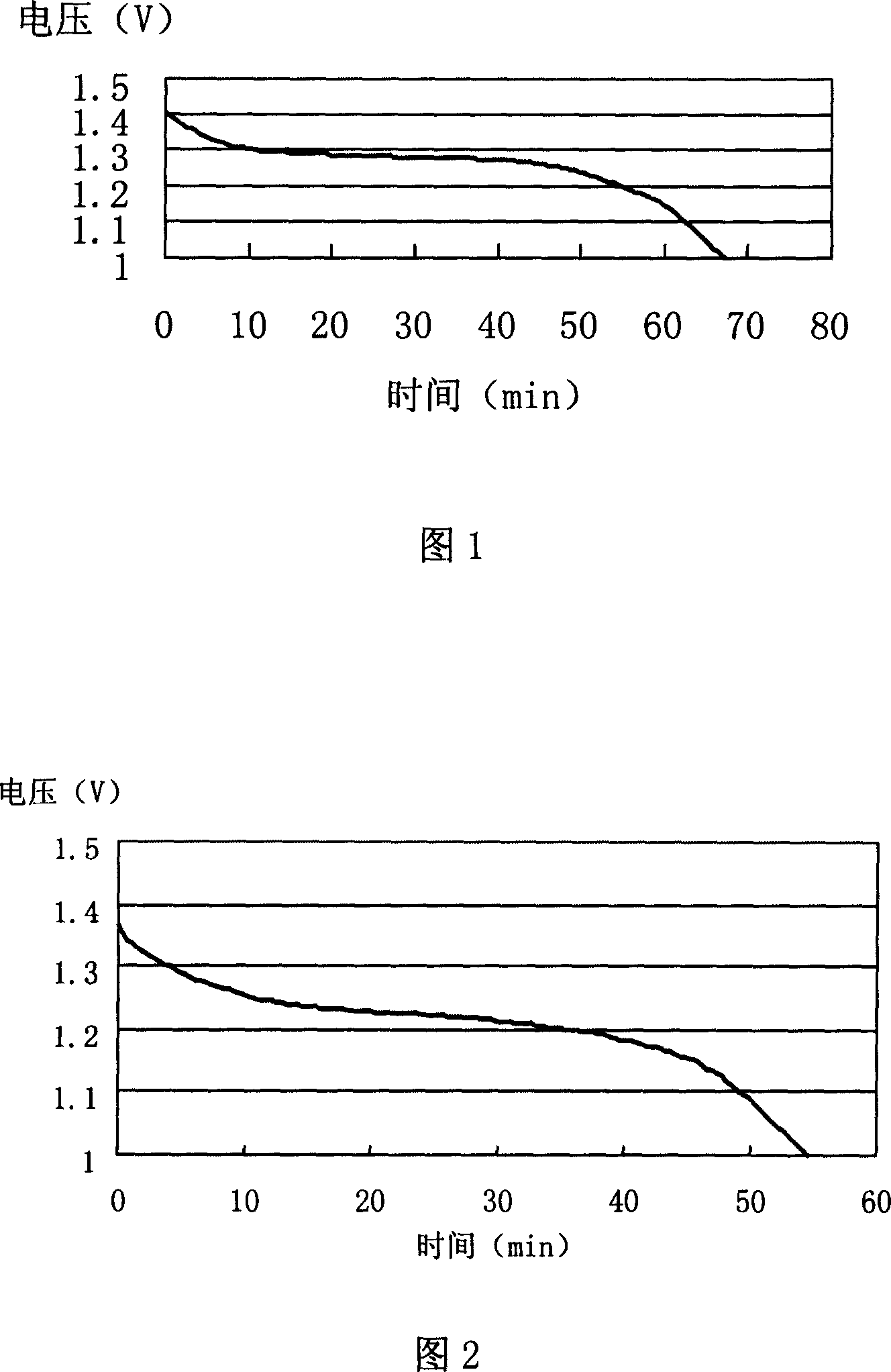

[0029] Production of the negative electrode: use metal cadmium as the anode, conductive metal mesh as the cathode, the main salt is cadmium sulfate solution, the conductive salt is nickel sulfate, and it is prepared by electroplating and depositing sponge cadmium metal on the cathode substrate. The electrolytic solution used during electroplating is composed of 0.1mol / L sulfuric acid solution, 0.1mol / L cadmium sulfate and mixed additives. One or three kinds of compositions, plating solution is calculated by 100 unit weight parts, the mixed additive of present embodiment is: OP emulsifier 0.5 part, wetting agent saccharin 0.05 part and 102A 0.2 part, 102A is from Shenzhen Aotejia technology Limited purchased wetting agent. The ratio of the anode...

Embodiment 2

[0041] Replace the production of AA batteries in Example 1 with the production of SC batteries, but replace the weight of the positive and negative plates with the weight of D-SC1700, and the additives in 100 parts by weight of the electrolyte are: 1.0 parts of OP emulsifier, saccharin 0.1 part, 102A0.3 part and other manufacturing processes are the same as in implementation 1. The surface of the obtained pole piece is porous but relatively dense, and there will be no material drop when washed with water, and the obtained pole piece has a good effect.

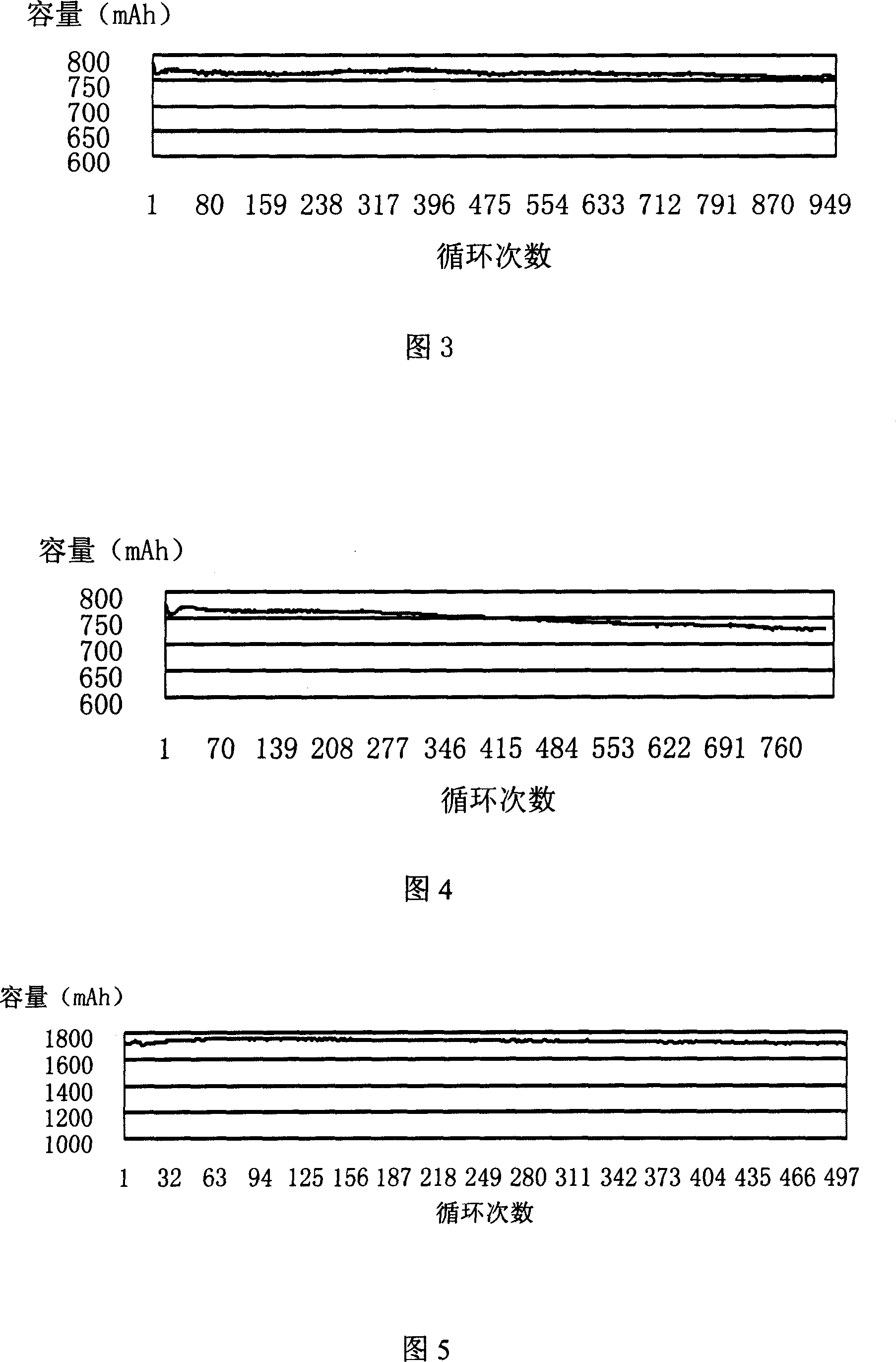

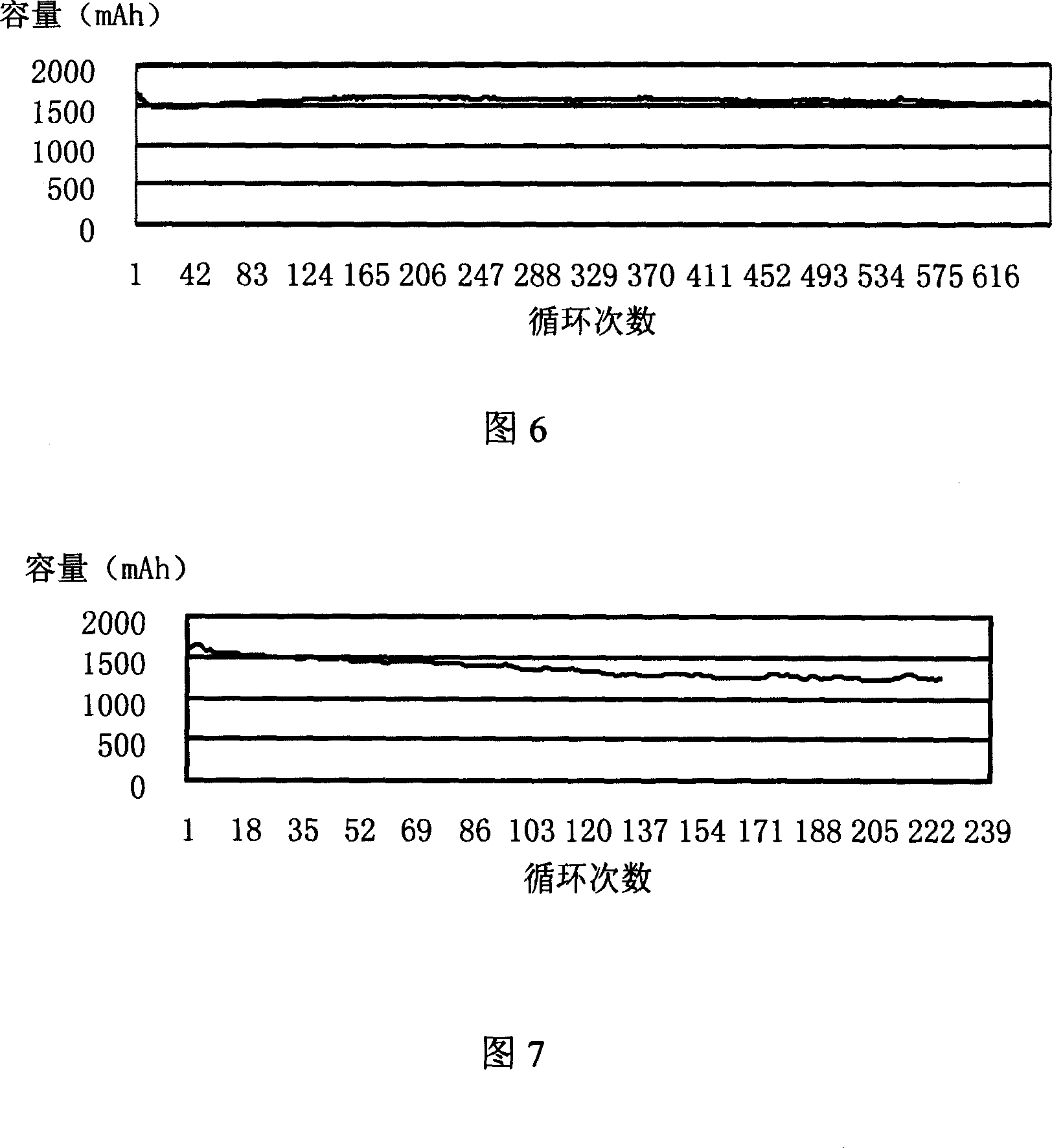

[0042] Its 1C capacity is as high as 1750mAh, but the main performance requirement of this type of battery is high-current discharge, so this example aims to verify its cycle performance of high-current discharge: 1C cycle: 1C charge, -DeltaV = 15mV time limit 75min, put aside for 20min, 1700mA Discharge to 1.0V, put it on hold for 30min, cycle, see Figure 5 of the attached drawing for details, 10C cycle: change the discharge c...

Embodiment 3

[0049] In Example 1, the temperature of the plating solution when making the AA battery was changed to 55° C., and the rest of the conditions remained unchanged.

[0050] Its charge-discharge curve is basically consistent with that in Example 1, and the cycle performance and capacity retention rate are also good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com