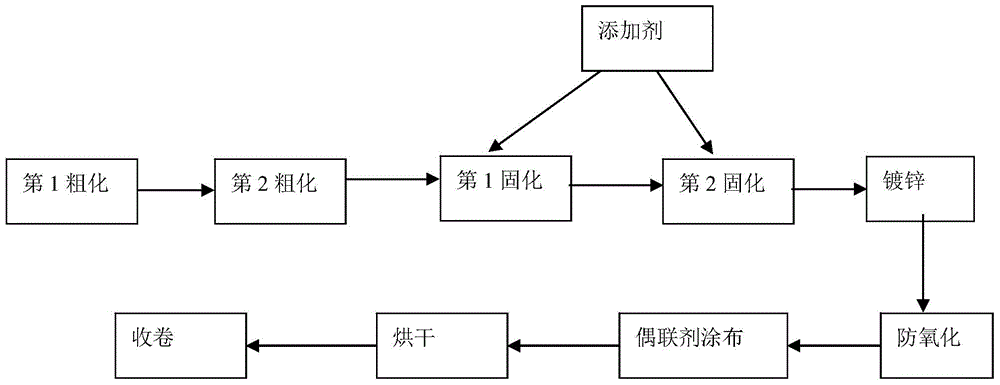

Surface treatment method for reducing copper powder on rough surface of copper foil

A treatment method and technology of copper foil, applied in the field of surface treatment to reduce the rough surface copper powder of copper foil, can solve the problems of too many rough surface copper powder, the effect is not obvious, and can not fundamentally effectively solve the problem of rough surface copper powder and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. The first roughening process: after the raw foil produced in the raw foil process, electroplating is performed in the roughening solution, and the current density of the first stage of the electroplating operation is 24A / dm 2 , the current density of the second stage is 5A / dm 2 , the temperature of the roughening solution is controlled at 30°C, the concentration of sulfuric acid in the roughening solution is 200g / L, Cu 2+ The concentration is 10g / L.

[0028] 2. The second roughening process: electroplate the copper foil after electroplating in the first roughening process in the roughening solution, and the current density of the first stage of the electroplating operation is 18A / dm 2 , the current density of the second stage is 4A / dm 2 , the temperature of the roughening solution is controlled at 30°C, the concentration of sulfuric acid in the roughening solution is 200g / L, Cu 2+ The concentration is 10g / L.

[0029] 3. The first curing process: electroplate the ...

Embodiment 2

[0037] 1. The first roughening process: after the raw foil produced in the raw foil process is electroplated in the roughening solution, the current density of the first stage of the electroplating operation is 30A / dm 2 , the current density of the second stage is 8A / dm 2 , the temperature of the roughening solution is controlled at 35°C, the concentration of sulfuric acid in the roughening solution is 220g / L, Cu 2+ The concentration is 14g / L.

[0038] 2. The second roughening process: electroplate the copper foil after electroplating in the first roughening process in the roughening solution, and the current density of the first stage of the electroplating operation is 20A / dm 2 , the current density of the second stage is 5A / dm 2 , the temperature of the roughening solution is controlled at 35°C, the concentration of sulfuric acid in the roughening solution is 220g / L, Cu 2+ The concentration is 14g / L.

[0039] 3. The first curing process: electroplate the copper foil afte...

Embodiment 3

[0047] 1. The first roughening process: after the raw foil produced in the raw foil process is electroplated in the roughening solution, the current density of the first stage of the electroplating operation is 35A / dm 2 , the current density of the second stage is 9A / dm 2 , the temperature of the roughening solution is controlled at 25°C, the concentration of sulfuric acid in the roughening solution is 190g / L, Cu 2+ The concentration is 12g / L.

[0048] 2. The second roughening process: electroplate the copper foil after electroplating in the first roughening process in the roughening solution, and the current density of the first stage of the electroplating operation is 25A / dm 2 , the current density of the second stage is 7A / dm 2 , the temperature of the roughening solution is controlled at 25°C, the concentration of sulfuric acid in the roughening solution is 190g / L, Cu 2+ The concentration is 12g / L.

[0049] 3. The first curing process: electroplate the copper foil afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com