Chromium plating method of automobile stainless steel tail gas decorating part

A technology for automobile exhaust and decorative parts, which is applied in the field of chrome plating of automobile stainless steel exhaust decorative parts, can solve the problems that the performance of the coating layer cannot meet the use requirements, the pretreatment work is not in place, and the chrome layer has a great influence, etc., and achieves excellent comprehensive performance. Save space and equipment, improve the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

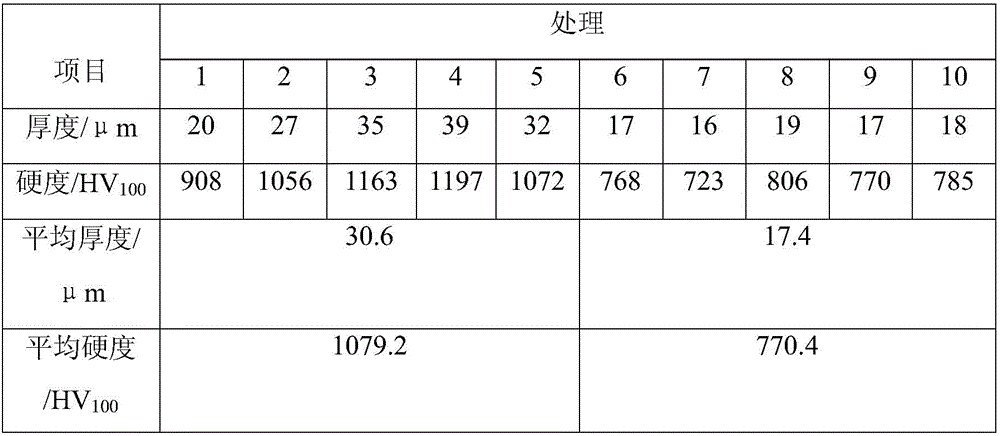

Examples

Embodiment 1

[0024] The chrome-plating method of automobile stainless steel tail gas trim of the present invention comprises the following steps:

[0025] (1) Chemical degreasing: Soak automotive stainless steel exhaust trim in chemical degreasing agent, keep the temperature at 70°C, and treat for 2 minutes, then take it out and rinse it with hot water at 50°C;

[0026] (2) Anode electrochemical degreasing: use alkaline solution as the electrolyte, use the decorative parts after chemical degreasing as the anode, and perform electrochemical degreasing treatment with a current density of 0.3A / dm 2 , the operating temperature is 65°C, and the degreasing time is 5 minutes. After the treatment, clean it with hot water at 50°C;

[0027] (3) Pickling activation: immerse the decorative parts after anodic electrochemical degreasing in a strong acid solution for 30 seconds, then clean the decorative parts that have completed the acid activation, and dry them for use;

[0028] (4) Electroplating: Ad...

Embodiment 2

[0035] The chrome-plating method of automobile stainless steel tail gas trim of the present invention comprises the following steps:

[0036] (1) Chemical degreasing: Soak the automotive stainless steel exhaust trim in chemical degreasing agent, keep the temperature at 75°C, and treat for 3 minutes, then take it out and rinse it with hot water at 59°C;

[0037] (2) Anode electrochemical degreasing: use alkaline solution as the electrolyte, use the decorative parts after chemical degreasing as the anode, and perform electrochemical degreasing treatment with a current density of 0.4A / dm 2 , the operating temperature is 73°C, and the degreasing time is 6 minutes. After the treatment, clean it with hot water at 60°C;

[0038] (3) Pickling activation: immerse the decorative parts after anodic electrochemical degreasing in a strong acid solution for activation for 40 seconds, then clean the decorative parts that have completed the acid activation, and dry them for use;

[0039] (4)...

Embodiment 3

[0046] The chrome-plating method of automobile stainless steel tail gas trim of the present invention comprises the following steps:

[0047] (1) Chemical degreasing: Soak the automotive stainless steel exhaust trim in chemical degreasing agent, keep the temperature at 78°C, and treat for 4 minutes, then take it out and rinse it with hot water at 63°C;

[0048] (2) Anode electrochemical degreasing: use alkaline solution as the electrolyte, use the decorative parts after chemical degreasing as the anode, and perform electrochemical degreasing treatment with a current density of 0.5A / dm 2 , the operating temperature is 77°C, and the degreasing time is 7 minutes. After the treatment, clean it with hot water at 65°C;

[0049](3) Pickling activation: immerse the decorative parts after anodic electrochemical degreasing in a strong acid solution for 50 seconds, then clean the decorative parts that have completed the acid activation, and dry them for use;

[0050] (4) Electroplating:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com