Lead-free metal luster gold glaze and preparation method thereof

A technology of lead-free metals and lead metals, applied in the field of material science, can solve the problems of difficult promotion of catering ceramic utensils, affect the health of operators, poor wear resistance of glazed surfaces, etc., achieve wide firing range, good metallic luster, and color stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

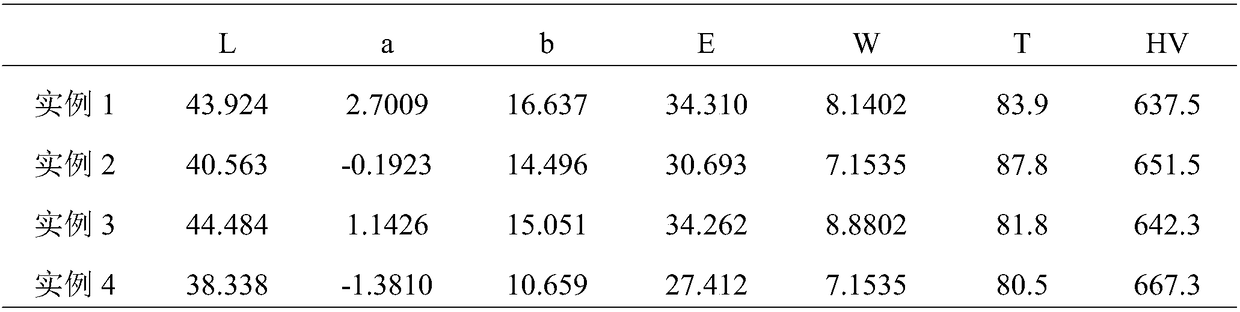

Examples

example 1

[0024] The mass percent that constitutes a kind of lead-free metallic luster golden glaze consists of: basic glass frit: 75%, MnO 2 :20%, CuO:3%, TiO 2 : 1%, NiO: 1%; the mass composition ratio of the basic glass frit is: 15 parts of zeolite powder, 45 parts of quartz powder, 10 parts of sodium carbonate, 10 parts of calcium fluoride, 10 parts of calcium carbonate, potassium carbonate 5 servings.

[0025] The melting temperature of the basic glass frit is 1260°C, and the temperature is kept for 2 hours. After water quenching and ball milling, usable frit powder is prepared, and its fineness is 100 mesh.

[0026] Put the above raw materials into a ball mill jar, wherein ball:material:water=2:1:0.8, and ball mill for 60 minutes to prepare a black glaze slurry. The glaze slurry prepared by the right is sprayed, coated or glazed on the surface of the green body, dried, and then the glazed green body is fired at a high temperature at a temperature of 1200 ° C, an oxidizing atmosp...

example 2

[0028] The mass percent that constitutes a kind of lead-free metallic luster golden glaze consists of: basic glass frit: 65%, MnO 2 :10%, CuO:10%, TiO 2 : 10%, NiO: 5%; the mass composition ratio of the basic glass frit is: 10 parts of zeolite powder, 35 parts of quartz powder, 15 parts of sodium carbonate, 15 parts of calcium fluoride, 15 parts of calcium carbonate, potassium carbonate 10 servings.

[0029] The melting temperature of the basic glass frit is 1260°C, and the temperature is kept for 2 hours. After water quenching and ball milling, the usable frit powder is prepared, and its fineness is 300 mesh.

[0030] Put the above raw materials into a ball mill jar, wherein ball:material:water=2:1:0.8, and ball mill for 60 minutes to prepare a black glaze slurry. The glaze slurry prepared by the right is sprayed, coated or glazed on the surface of the green body, dried, and then the glazed green body is fired at a high temperature at a temperature of 1300 ° C, an oxidizing...

example 3

[0032] The mass percentage that constitutes a kind of lead-free metallic luster golden glaze consists of: basic glass frit: 70%, MnO 2 :15%, CuO:10%, TiO 2 : 4%, NiO: 1%; the mass composition ratio of the basic glass frit is: 12 parts of zeolite powder, 40 parts of quartz powder, 15 parts of sodium carbonate, 15 parts of calcium fluoride, 12 parts of calcium carbonate, potassium carbonate 8 servings.

[0033] The melting temperature of the basic glass frit is 1260°C, and the temperature is kept for 2 hours. After water quenching and ball milling, a usable frit powder is prepared, and its fineness is 200 mesh.

[0034] Put the above raw materials into a ball mill jar, wherein ball:material:water=2:1:0.8, and ball mill for 60 minutes to prepare a black glaze slurry. The glaze slurry prepared by the right is sprayed, coated or glazed on the surface of the green body, dried, and then the glazed green body is fired at a high temperature at a temperature of 1250 ° C, an oxidizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com