Gas shielded welding wire matched with weather-resistant bridge steel Q690qE and preparation method thereof

A technology of gas shielded welding wire and bridge, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of unsightly welding seam, poor welding performance of welding wire, poor weather resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

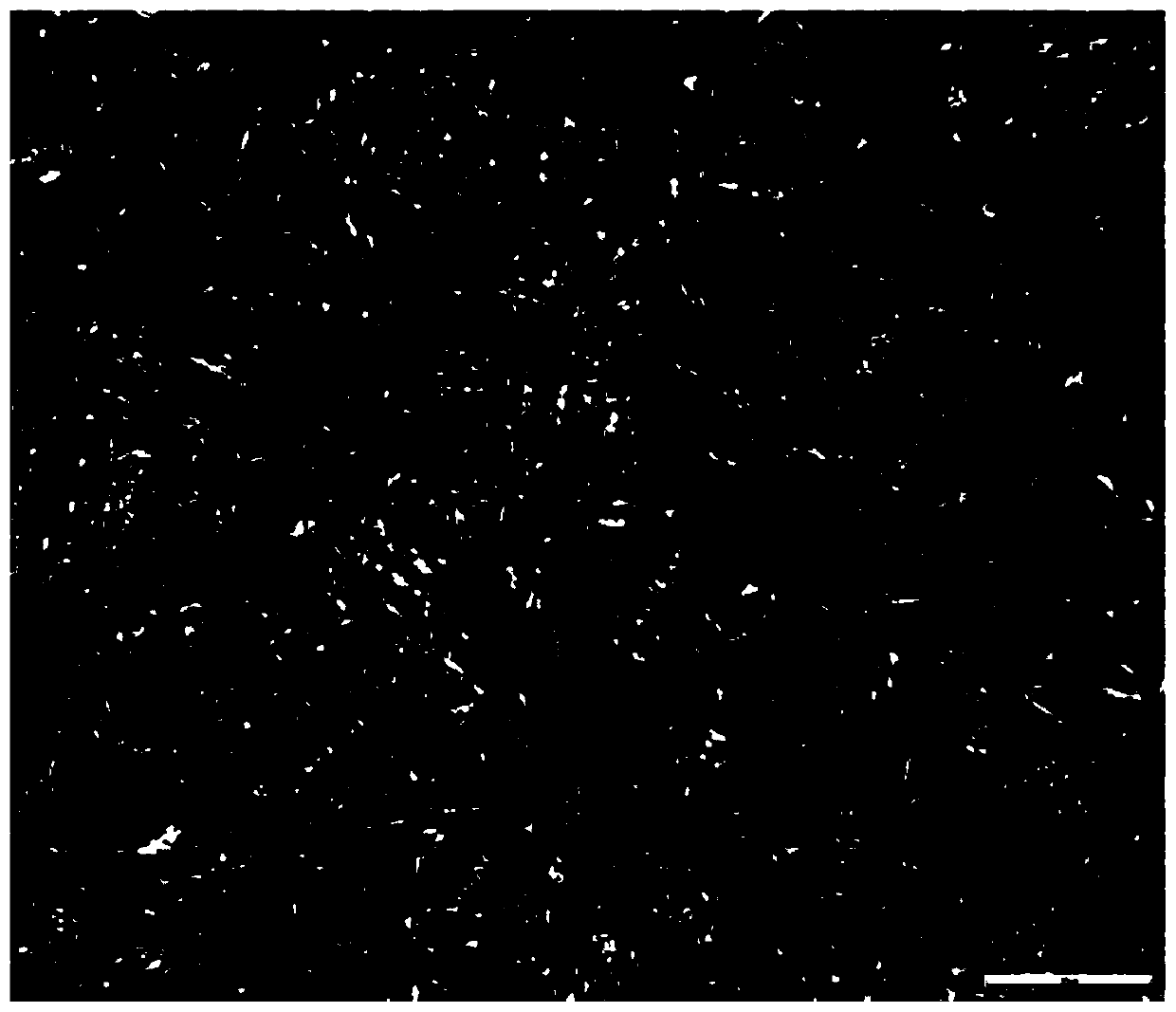

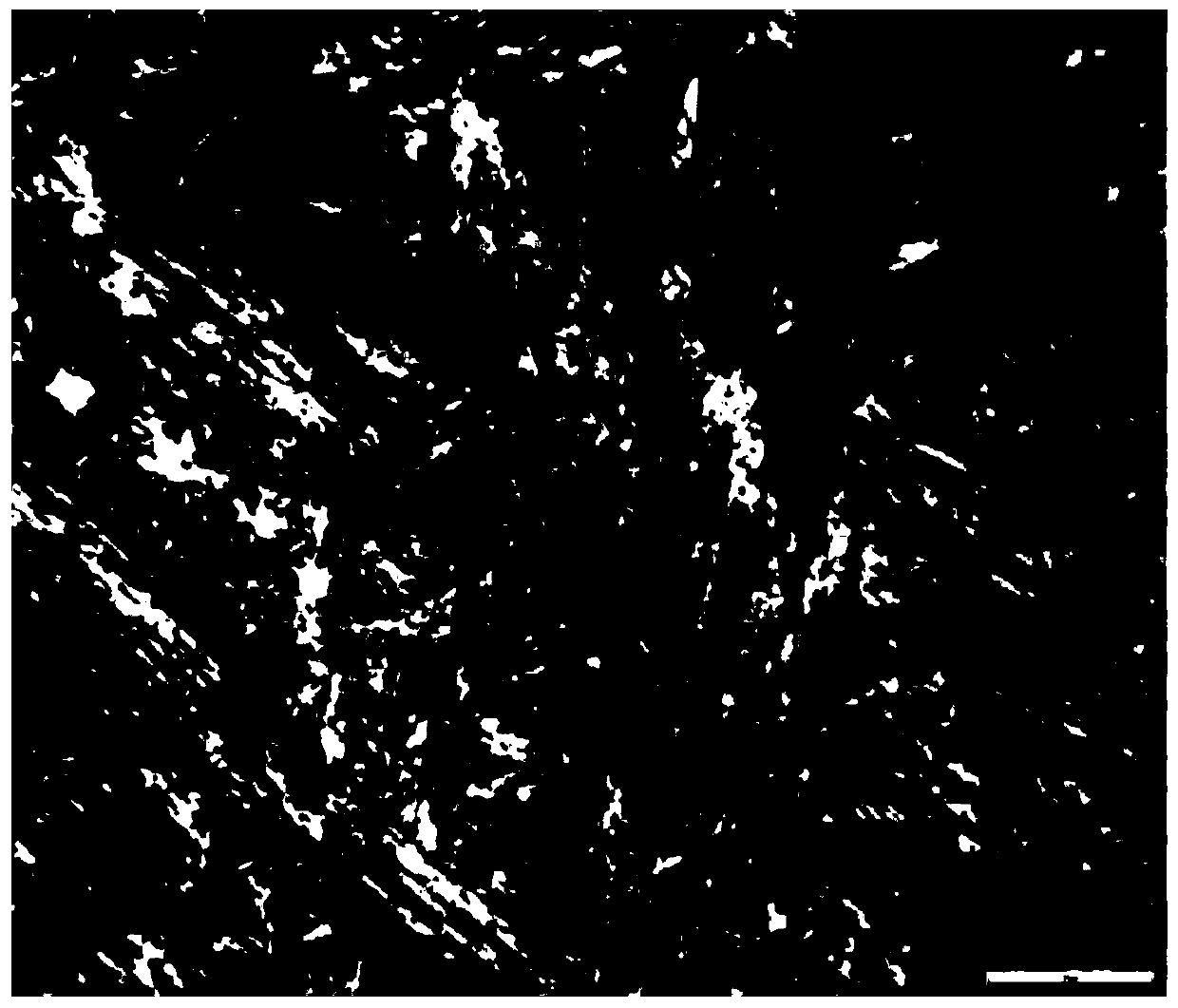

Image

Examples

Embodiment 1

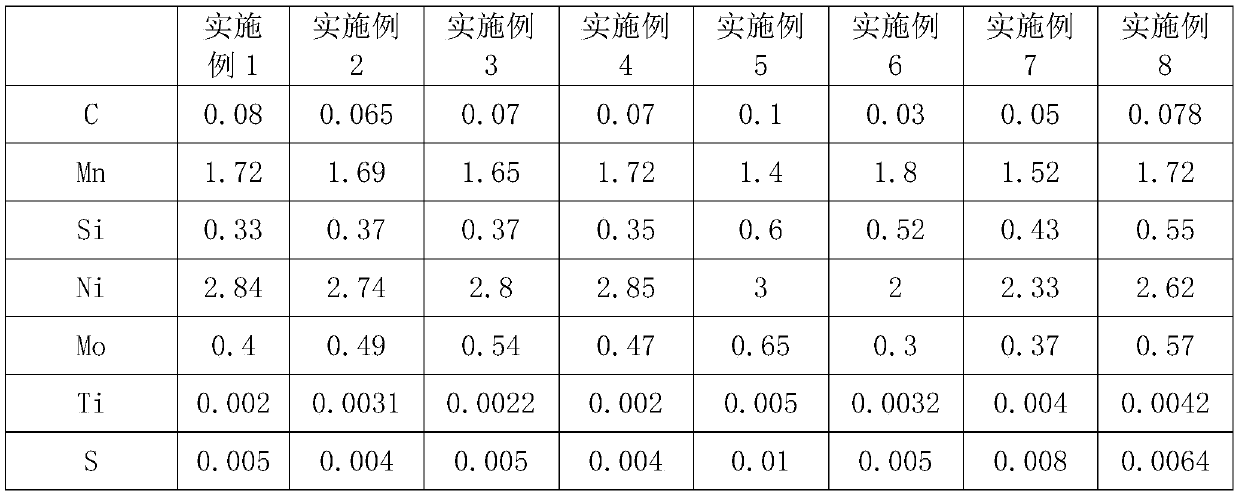

[0055] According to the composition of the original wire rod, the original wire rod is prepared by the preparation method in the prior art; wherein, in the present embodiment, the composition of the original wire rod is calculated as:

[0056] C: 0.078%; Mn: 1.78%; Si: 0.37%; Ni: 2.75%; Mo: 0.45%; Ti: 0.0024%, S: 0.004%; P: 0.010%; Cr: 0.42%; Cu: 0.02%; V: 0.0048%; the balance is Fe and other impurities.

[0057] Prepare welding wire as follows:

[0058] (a) Prepare the wire rod according to the above formula, cooperate with drawing powder, and rough draw the described wire rod to a diameter of 4.2mm; in the rough drawing process,

[0059] (b) Annealing the wire rod after the above step (a), and then removing the oxide layer on the surface of the wire rod by a belt sander, wherein, the operating parameters of the belt sander: the starting frequency of the main shaft is 12-24HZ, the main shaft Motor frequency ≤48HZ.

[0060] (c) Secondary rough drawing of the wire rod treate...

Embodiment 2

[0073] According to the composition of the original wire rod, the original wire rod is prepared by the preparation method in the prior art; wherein, in the present embodiment, the composition of the original wire rod is calculated as:

[0074] C: 0.069%; Mn: 1.70%; Si: 0.39%; Ni: 2.72%; Mo: 0.57%; Ti: 0.0027%; V: 0.0033%; the balance is Fe and other impurities.

[0075] Prepare welding wire as follows:

[0076] (a) Prepare the wire rod according to the above formula, cooperate with the drawing powder, and roughly draw the wire rod to a diameter of 4.2 mm;

[0077] (b) Annealing the wire rod after the above step (a), and then removing the oxide layer on the surface of the wire rod by a belt sander, wherein, the operating parameters of the belt sander: the starting frequency of the main shaft is 12-24HZ, the main shaft Motor frequency ≤48HZ.

[0078] (c) Secondary rough drawing of the wire rod treated in the above step (b) until the diameter of the wire rod is 2.34 mm.

[00...

Embodiment 3

[0091] According to the composition of the welding wire, the original wire rod is prepared by the preparation method in the prior art; wherein, in the present embodiment, the composition of the original wire rod is calculated as:

[0092] C: 0.074%; Mn: 1.67%; Si: 0.36%; Ni: 2.78%; Mo: 0.57%; Ti: 0.0025%; V: 0.005%; the balance is Fe and other impurities.

[0093] Prepare welding wire as follows:

[0094] (a) Prepare the wire rod according to the above formula, cooperate with drawing powder, and roughly draw the wire rod to a diameter of 4.23mm;

[0095] (b) Annealing the wire rod after the above step (a), and then removing the oxide layer on the surface of the wire rod by a belt sander, wherein, the operating parameters of the belt sander: the starting frequency of the main shaft is 12-24HZ, the main shaft Motor frequency ≤48HZ.

[0096] (c) Secondary rough drawing of the wire rod treated in the above step (b) until the diameter of the wire rod is 2.2 mm.

[0097] (d) Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com