Aluminum alloy with excellent decorativeness

An aluminum alloy and decorative technology, applied in the field of aluminum alloys, can solve the problems of poor metal luster and reduced mechanical properties of color zipper elements, and achieve the effects of good corrosion resistance, stress corrosion resistance and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] An aluminum alloy billet (40 mm diameter) having the composition shown in the left column of Table 1 was cast, homogenized, and then directly extruded through an extruder to produce an extruded rod with a diameter of 8 mm. This extruded rod was used as an experimental material, and cold workability was evaluated. Also, the extruded rod was rolled to a thickness of 1.36 mm at room temperature and annealed, then rolled to a thickness of 0.22 mm at room temperature, and then the surface passivation aluminum (anodized oxide film ) hardness and hue. Also, continuous casting was performed for the compositions given in the left column of Table 1, and hot workability was evaluated by performing hot rolling immediately after casting. The same evaluation was also performed for a normal material (comparative material).

[0046] These results are given in the right column of Table 1.

[0047] No.*1

Al alloy composition (mass%)

cold workabil...

example 2

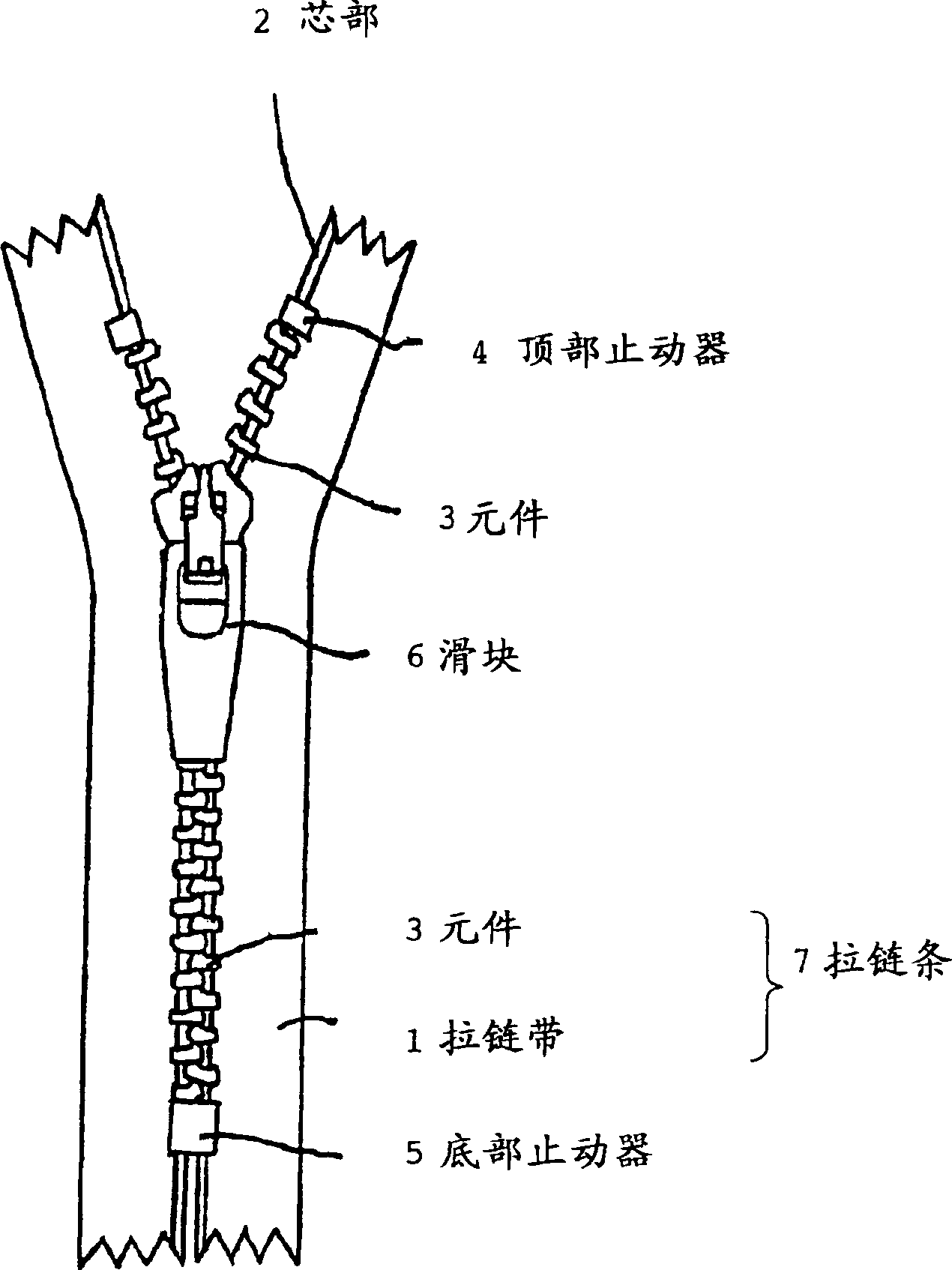

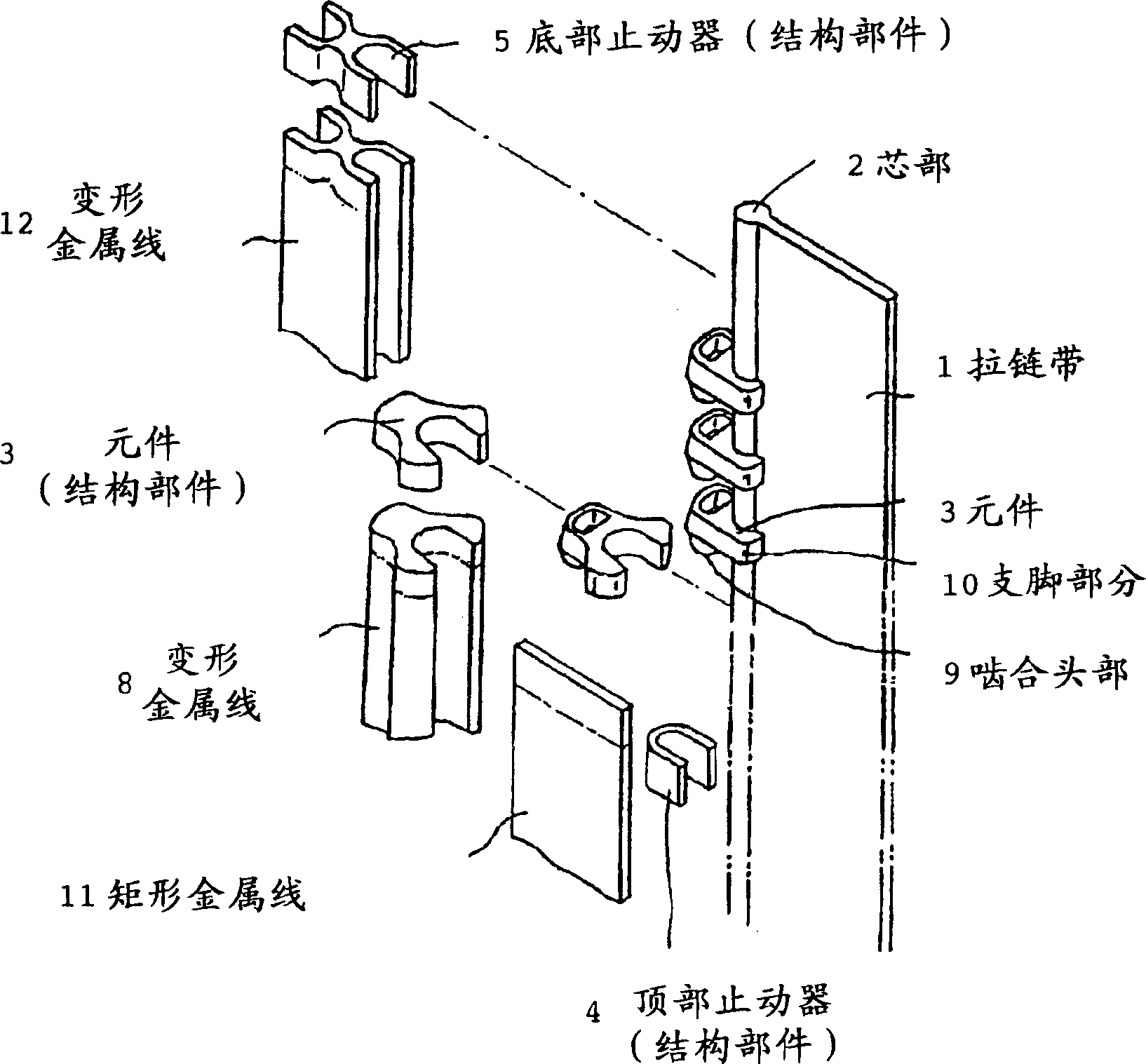

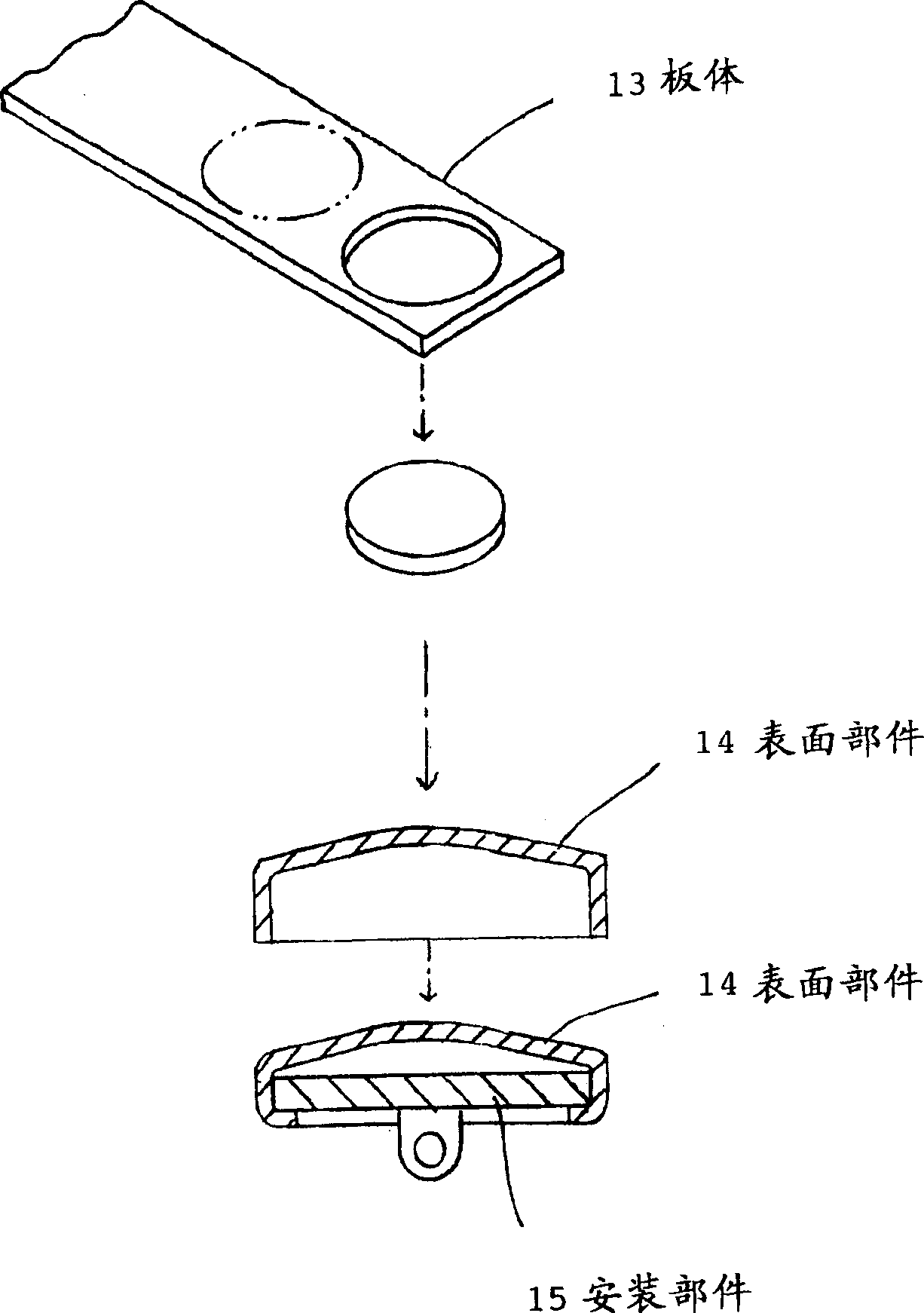

[0087] Produced as figure 1and 2 Zipper parts shown. As shown in Table 2, the strength of the zipper is better than that of the zipper of ordinary materials. Also, the anodized oxide film is transparent and has a high L* value, so it can be dyed for a good decorative appearance. Ordinary materials having the same strength as the material of the present invention have lower L* values and therefore have poorer decorative properties. F-strength is a measurement of the element pull-out strength of an element that has been secured to a zipper tape.

[0088]

[0089] The aluminum alloy of the present invention has the strength, hardness and other mechanical properties required for its target use, and also has good metallic luster, so that the aluminum alloy has a prominent decorative property. The alloy is particularly useful when used in zipper elements, stops, sliders, pull tabs and other structural components of zippers or in snaps, common buttons and various type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com