Multi-layer coating film formation method

A multi-layer coating film and coating film technology, which is applied to the device, coating, and special surface of the surface coating liquid, can solve the problems such as the water resistance and adhesion of the coating film, and achieve excellent appearance and excellent water resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

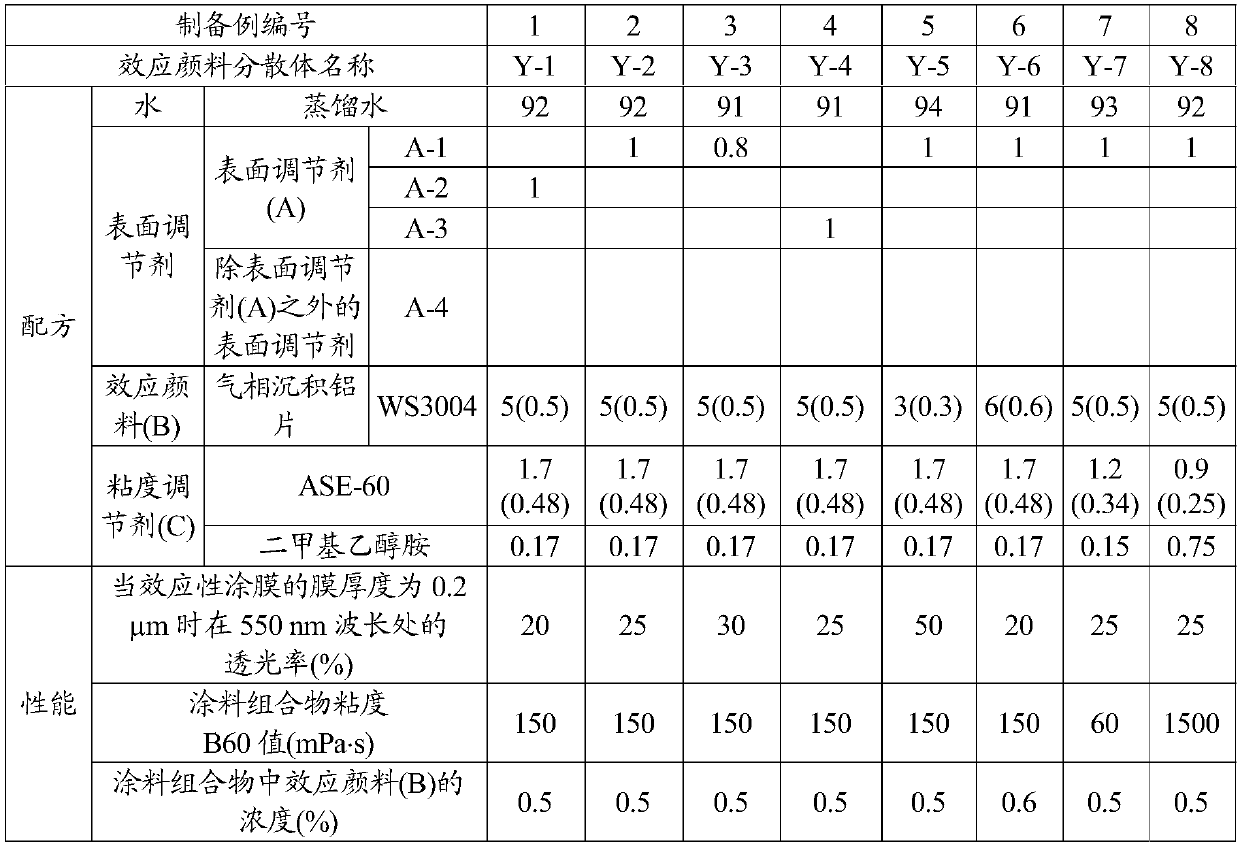

preparation example 1

[0192] With 92 parts of distilled water, 1 part of surface conditioner (A-2), 5 parts (solid content is 0.5 part) Hydroshine WS-3004 (aqueous vapor deposition aluminum flake pigment, produced by Eckart, solid content: 10%; internal solvent : Isopropanol, average particle size D50: 13 μm, thickness: 0.05 μm; the surface has been treated with silica), 1.7 parts (0.48 parts of solid content) AcrysolASE-60 (polyacrylic viscosity modifier, produced by The Dow Chemical Company, solid content: 28%) and 0.17 parts of dimethylethanolamine were blended, stirred and mixed, whereby an effect pigment dispersion (Y-1) was prepared.

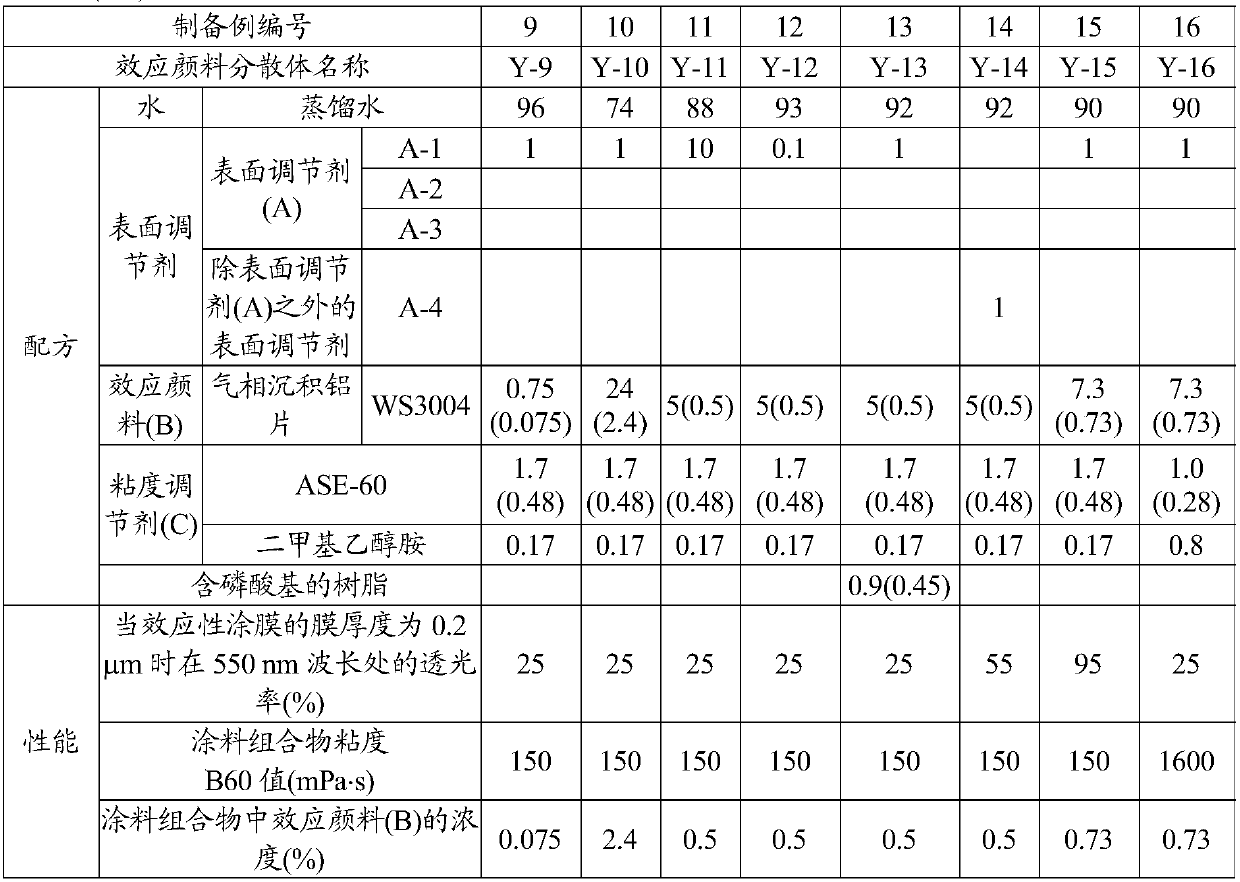

preparation example 2 to preparation example 15

[0194] Effect pigment dispersion (Y-2) to effect pigment dispersion (Y-16) were obtained in the same manner as Preparation Example 1, but using the formulations shown in Table 2.

[0195] The values in brackets in Table 2 are the solid content.

[0196]

[0197] The values in brackets in Table 2 (continued) are the solid contents.

[0198]

[0199] 4. Preparation of the object to be coated

[0200] Production of coated object 1

[0201] A cationic electrodeposition coating composition "Erekuron (エレクロン) 9400HB" (trade name, manufactured by Kansai Paint Co., Ltd., a cationic resin based on an amine-modified epoxy resin containing a blocked polyisocyanate compound) was applied by electrodeposition. as a curing agent) onto a degreased and zinc-phosphate-treated steel plate (JISG3141, size: 400×300×0.8 mm) to a film thickness of 20 μm when cured. The obtained film was heated at 170° C. for 20 minutes to be cured by crosslinking, whereby a coated object 1 was obtained...

Embodiment 1

[0206] The colored paint composition (X-1) "WP-522HN-2.0" (trade name, manufactured by Kansai Paint Co., Ltd., water-based polyester resin The intermediate coating composition, the L* value of the coating film to be obtained: 20) is applied to the object to be coated 1 until the thickness of the cured film is 20 μm. After allowing the resulting film to stand for 3 minutes, preheating was performed at 80° C. for 3 minutes. In addition, the effect pigment dispersion (Y-1) prepared as above was adjusted to have the viscosity of the coating composition shown in Table 2, and under the condition that the temperature of the booth (booth) was 23° C. and the humidity was 68%. , which was coated with a robot bell (manufactured by ABB) to a dry coating film thickness of 0.1 μm. The resultant was then allowed to stand at 80° C. for 3 minutes. Subsequently, the clear coating composition (Z-1) "KINO6500" ( Trade name, produced by Kansai Paint Co., Ltd., two-component organic solvent-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com