Aluminum sheet pigment, aluminum sheet pigment-contained coating composite, aluminum sheet pigment-contained printing ink composite and membranes obtained from aluminum sheet pigment

A technology of pigments and aluminum flakes, applied in the direction of fibrous fillers, etc., can solve the problems of poor production capacity, narrow application range, disproportion between performance and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

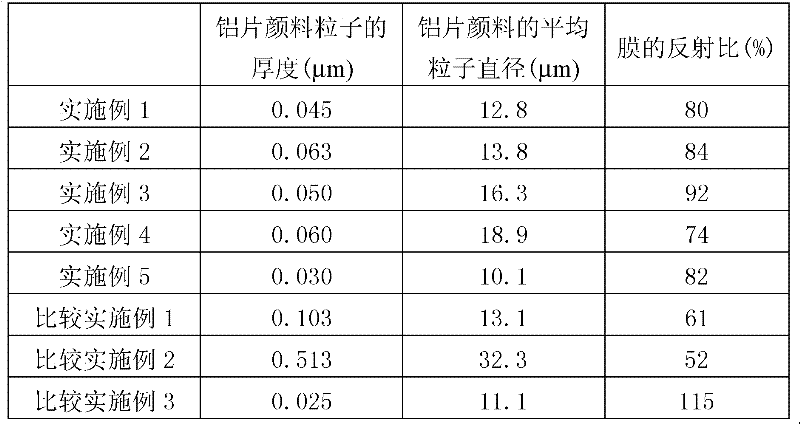

Examples

Embodiment 1

[0057] A mixture of 1Kg of atomized aluminum spherical powder with an average particle diameter of 3μm, 6L of mineral essential oil and 100g of oleic acid is added to a ball mill with an internal diameter of 500mm and a length of 180mm, and 50Kg of steel balls with a diameter of 1.8mm are used to The first stage grinding was carried out for 8 hours at 33 rpm (corresponding to 55% of the critical rotation frequency).

[0058] After the first stage of grinding, the slurry in the ball mill is washed with mineral spirits, and the solid-liquid is separated by a disc filter. In terms of aluminum metal, 500g of the gained filter cake (non-volatile component content: 85%) returns to the same type of ball mill that contains 50Kg of 1.5mm steel balls, then adds 5L of mineral essential oil and 100g of oleic acid, and then The second grinding stage was performed at 40 rpm (corresponding to 67% of the critical rotation frequency) for 20 hours.

[0059] After the second stage of grinding i...

Embodiment 2

[0061] The same conditions as in Example 1 were used to obtain a paste containing aluminum flake pigments, except that steel balls with a diameter of 1.0 mm were used for the second stage of grinding.

Embodiment 3

[0063] Except for using atomized aluminum spherical powder with an average particle diameter of 5 μm as the raw material, the same conditions as in Example 1 were used to obtain a paste containing aluminum flake pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com