Vacuum plating under-coating paint as well as application and preparation method of vacuum platable hard thin film for IML prepared from vacuum plating under-coating paint

A vacuum plating and coating technology, which is applied in the field of coatings and thin films, can solve the problems of high production cost and large amount of coating, and achieve the effects of reducing raw material costs, reducing coating consumption, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

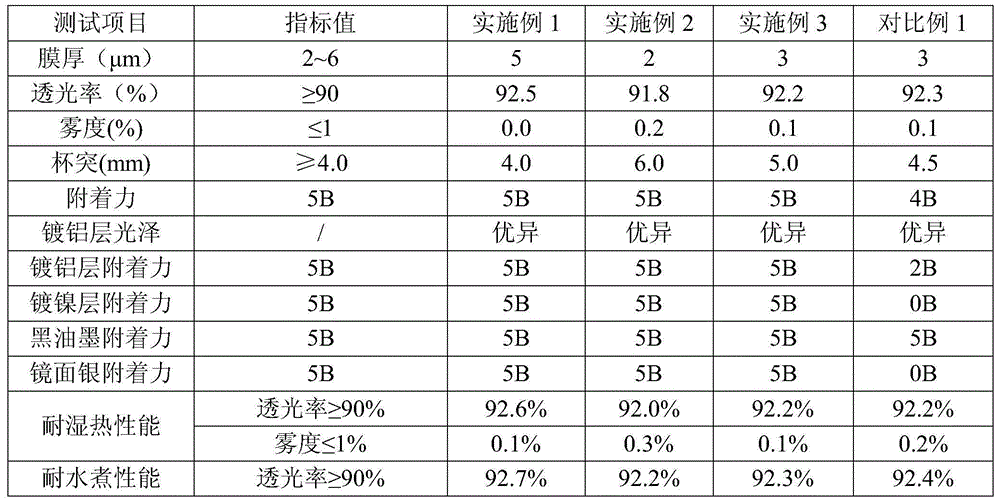

Examples

Embodiment 1

[0035] Preparation of Vacuum Primer Coatings for IML:

[0036] (1) Mix 50g of organic solvent (acetone / butyl acetate=1:1), 10g of reactive diluent (DSM AgiSyn2836), and 2g of leveling agent (BYK-352);

[0037] (2) Add 25g urethane acrylate (Dainippon Ink Chemical UA-711BT-1 / Changxing Chemical 6195-100=2: 1), 6g epoxy acrylate (cyanate EB3300) to the mixture obtained in step (1), 5g modified acrylate (BASF PA9083), high-speed stirring to disperse evenly;

[0038] (3) Add 2g photoinitiator (Ciba Darocur 1173 / BASF Lucirin TPO=2: 1) in the mixture that step (2) obtains, disperse evenly, filter, obtain the vacuum-plating primer coating that is used for PET substrate .

Embodiment 2

[0040] Preparation of Vacuum Primer Coatings for IML:

[0041] (1) Mix 70g of organic solvent (ethyl acetate / methyl isobutyl ketone=1:1), 5g of reactive diluent (Eternal Chemical EM231), and 0.5g of leveling agent (BYK-358N);

[0042] (2) Add 10g polyurethane acrylate (Bayer XP2491 / Cytec EB1290N=3:2), 8g epoxy acrylate (Changxing Chemical DR-G991), 5g modified acrylate (Changxing Chemical) to the mixture obtained in step (1). Chemistry 6071-2), high-speed stirring to disperse evenly;

[0043] (3) Add 1 g of photoinitiator (BASF Irgacure 184 / BASF Irgacure 907=2:1) to the mixture obtained in step (2), disperse evenly, and filter to obtain a vacuum primer coating for PET substrates.

Embodiment 3

[0045] Preparation of Vacuum Primer Coatings for IML:

[0046] (1) Mix 60g of organic solvent (butanone / butyl acetate=2:1), 8g of reactive diluent (Eternal Chemical EM235), and 1g of leveling agent (Dego FLow370);

[0047] (2) Add 15g polyurethane acrylate (Changxing Chemical DR-U150 / Cytec EB8602=2:1), 5g epoxy acrylate (Cytec EB3703), 10g modified acrylate ( Changxing Chemical 6070), high-speed stirring to disperse evenly;

[0048] (3) Add 1.5g photoinitiator (BASF Irgacure 184 / BASF Lucirin TPO=2:1) to the mixture obtained in step (2), disperse evenly, and filter to obtain a vacuum primer coating for PET substrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com