Method for preparing two-sided polyimide / silver compound film

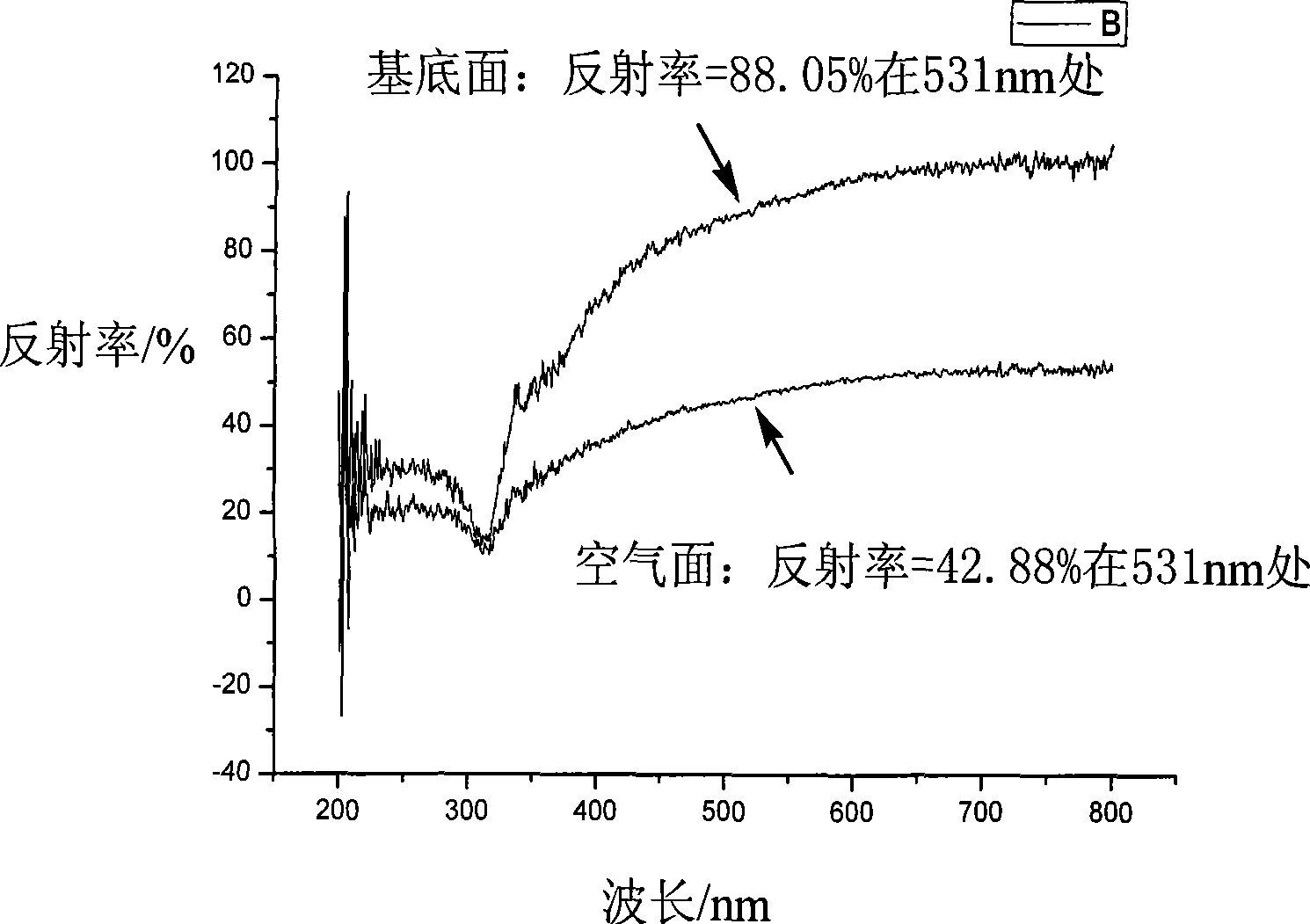

A technology of polyimide and composite film, applied in the direction of coating, etc., can solve the problem that the surface of the composite film does not have metallic luster, etc., and achieve the effect of good industrialization prospects, good interface bonding performance, and good metallic luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

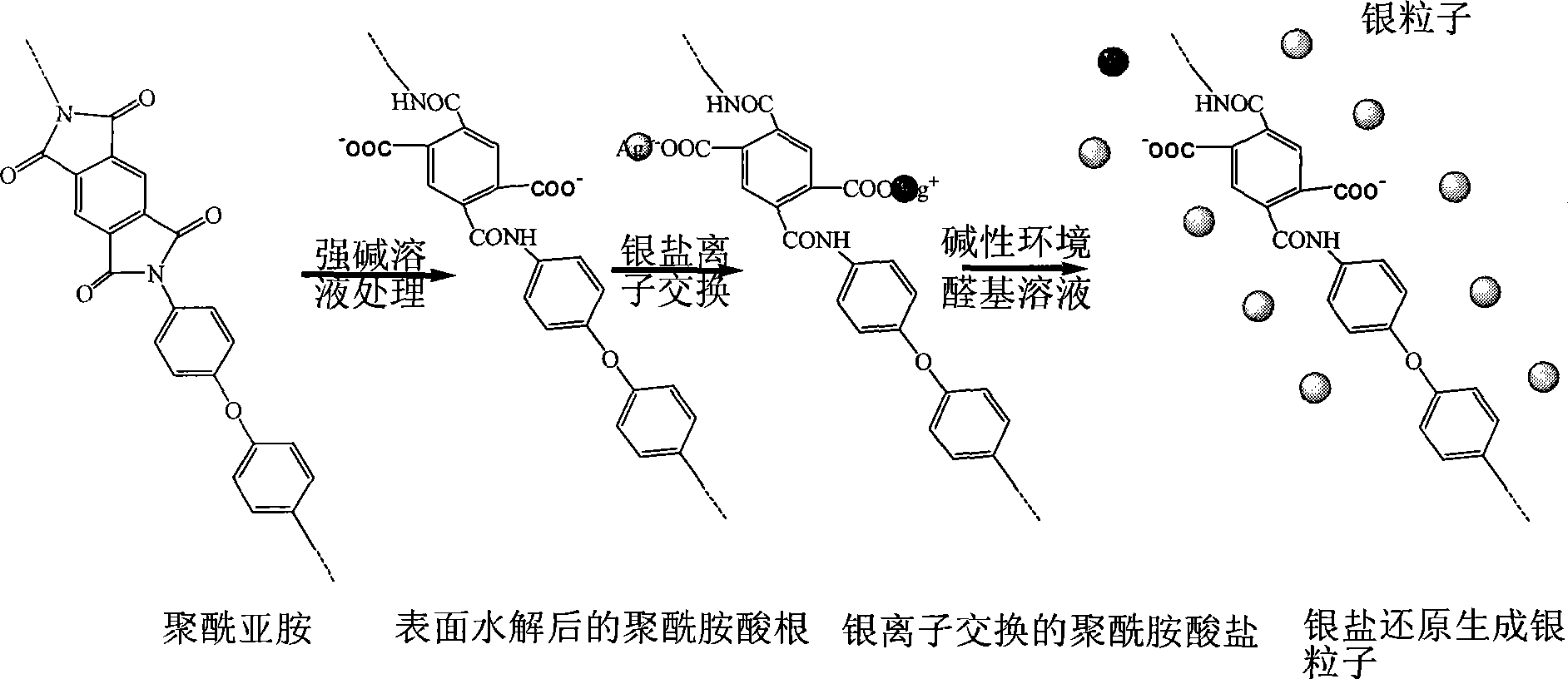

Method used

Image

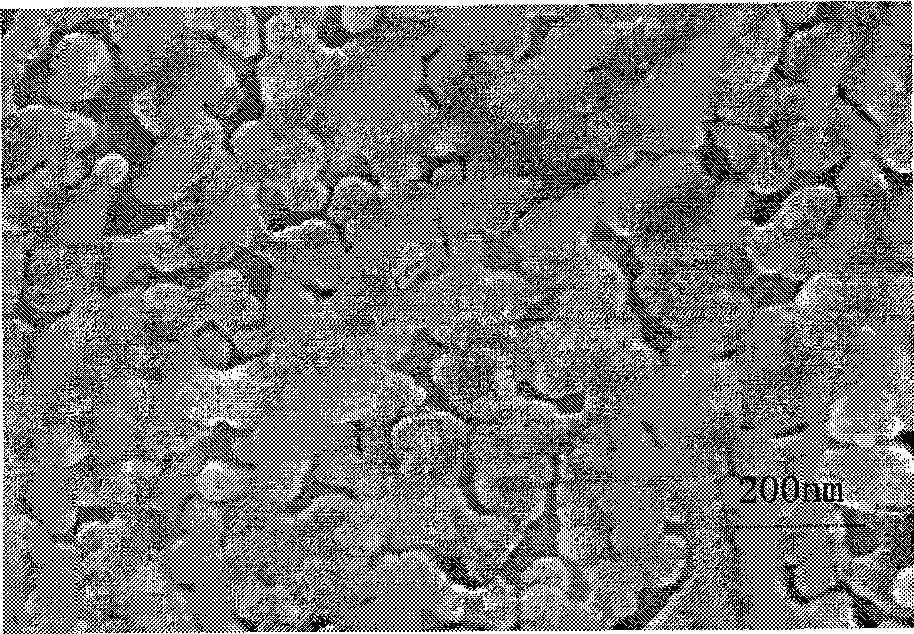

Examples

Embodiment 1

[0033] A: Cut the polyimide film with a thickness of 0.07mm into 80mm×100mm, ultrasonically in deionized water for 15 minutes to remove the dirt on the surface, immerse in 4mol / l potassium hydroxide solution at room temperature for 7 hours and then take it out , put the impregnated film in deionized water for 5 minutes to remove the attached potassium hydroxide;

[0034] B: Put the film treated in step A into 0.4mol / l silver nitrate solution and keep it for 5 hours, take it out and wash it;

[0035] C: Prepare 250 milliliters of potassium hydroxide solution of 0.01 mol / l, and add 10 grams of glucose (equivalent to the concentration of aldehyde group in the solution is 0.22 mol / l), immerse the film treated in step B in the reaction solution for 15 minutes After taking it out and cleaning it, a double-sided highly conductive and highly reflective polyimide / silver composite film can be obtained.

Embodiment 2

[0037] A: Cut the polyimide film with a thickness of 0.07mm into 50mm×50mm, ultrasonically in deionized water for 10 minutes to remove the dirt on the surface, immerse in 2mol / l sodium hydroxide solution at room temperature for 10 hours and then take it out , put the impregnated film in deionized water for 5 minutes to remove the attached sodium hydroxide;

[0038] B: Put the film treated in step A into 0.4mol / l silver nitrate solution and keep it for 3 hours, take it out and wash it;

[0039] C: prepare 250 milliliters of potassium hydroxide solution of 0.01mol / l, and add 5 grams of glucose (equivalent to the molar concentration of aldehyde group in the solution is 0.11mol / l), immerse the film processed in step B in the reaction solution, 45 Minutes later, take it out and wash it, and you will get a double-sided highly conductive and highly reflective polyimide / silver composite film.

Embodiment 3

[0041] A: Cut the polyimide film with a thickness of 0.07mm into 80mm×100mm, ultrasonically in deionized water for 15 minutes to remove the dirt on the surface, immerse in 4mol / l potassium hydroxide solution at room temperature for 7 hours and then take it out , put the impregnated film in deionized water for 5 minutes to remove the attached potassium hydroxide;

[0042] B: Put the film treated in step A into 0.4mol / l silver nitrate solution and keep it for 3 hours, take it out and wash it;

[0043] C: prepare 250 milliliters of potassium hydroxide solution of 0.1mol / l, and add 2 grams of glucose (equivalent to the molar concentration of aldehyde group in the solution is 0.044mol / l), the film processed by step B is immersed in the reaction solution, 15 Minutes later, take it out and wash it, and you will get a double-sided highly conductive and highly reflective polyimide / silver composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com