Patents

Literature

91results about How to "Easy to streamline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyimide nano-fiber membrane with crosslinked structure and preparation thereof

ActiveCN102766270AImprove mechanical propertiesThe degree of cross-linking can be controlledMonocomponent synthetic polymer artificial filamentFiberPolymer science

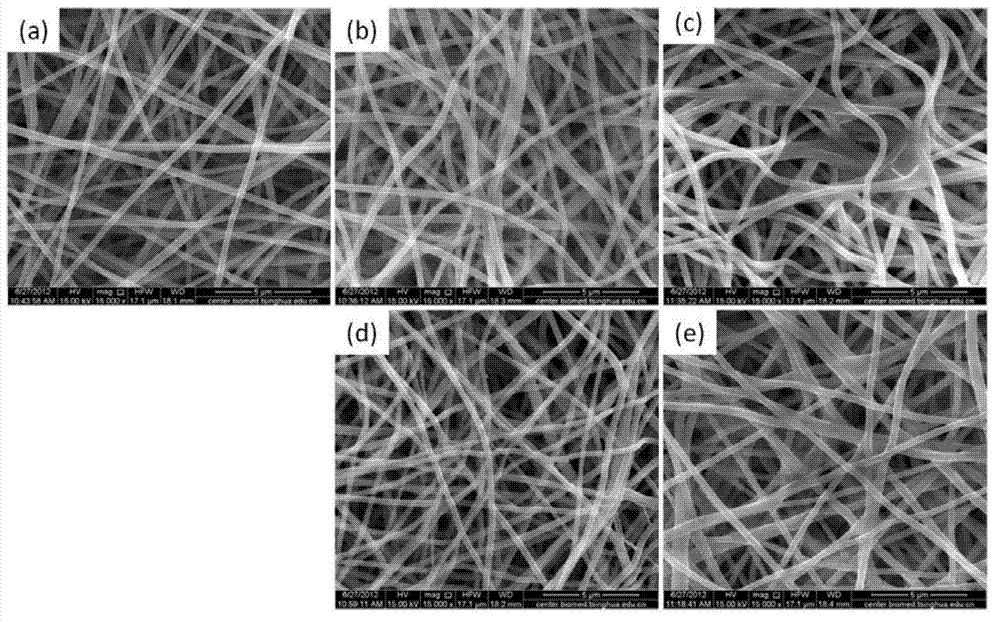

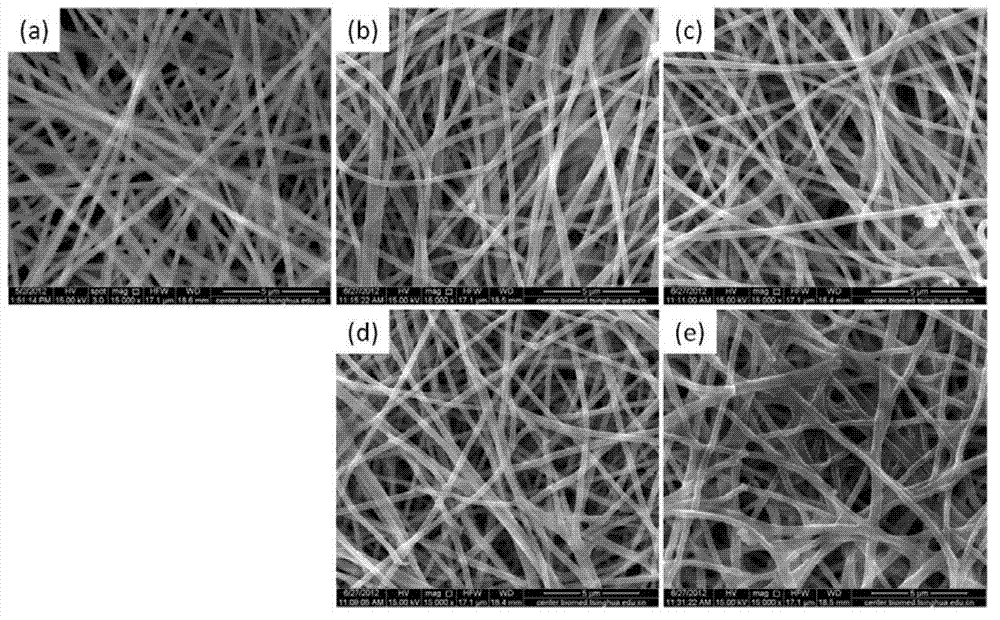

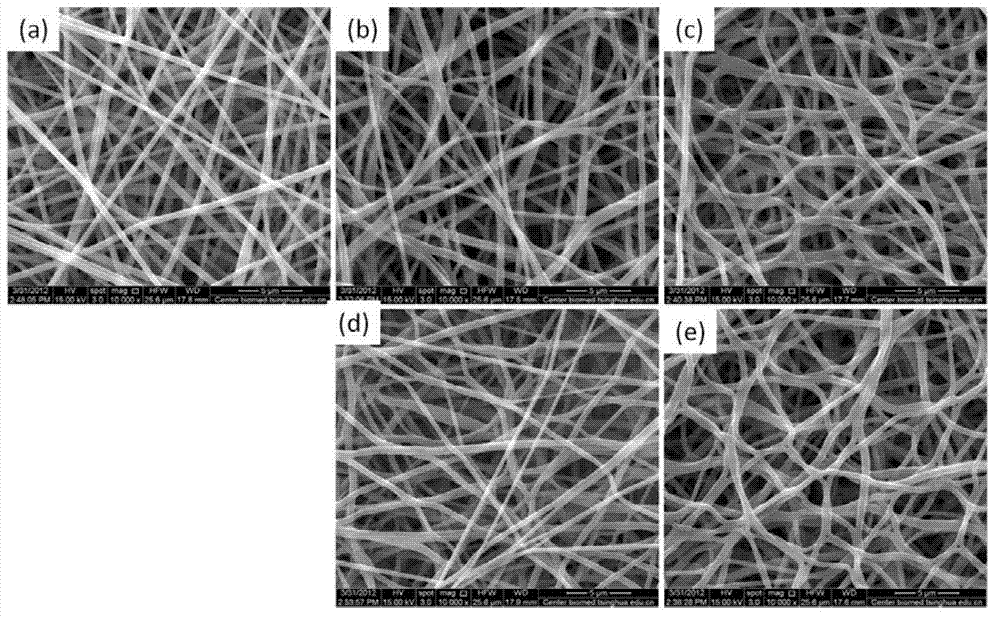

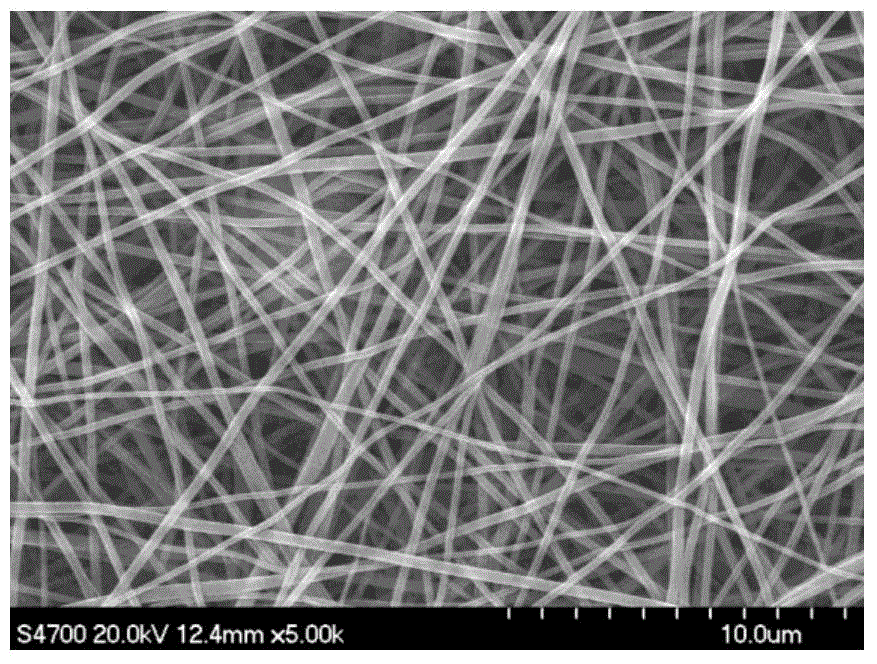

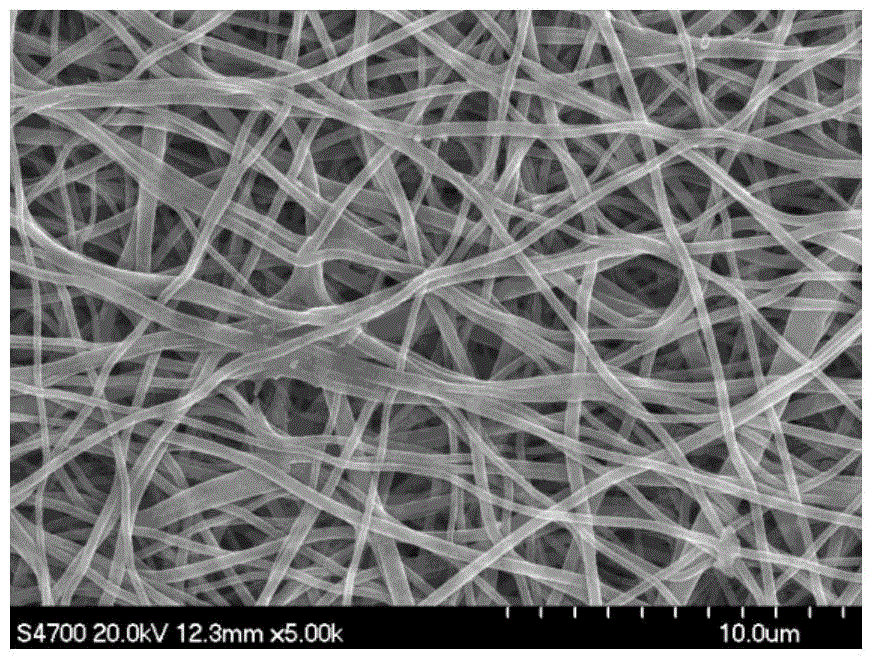

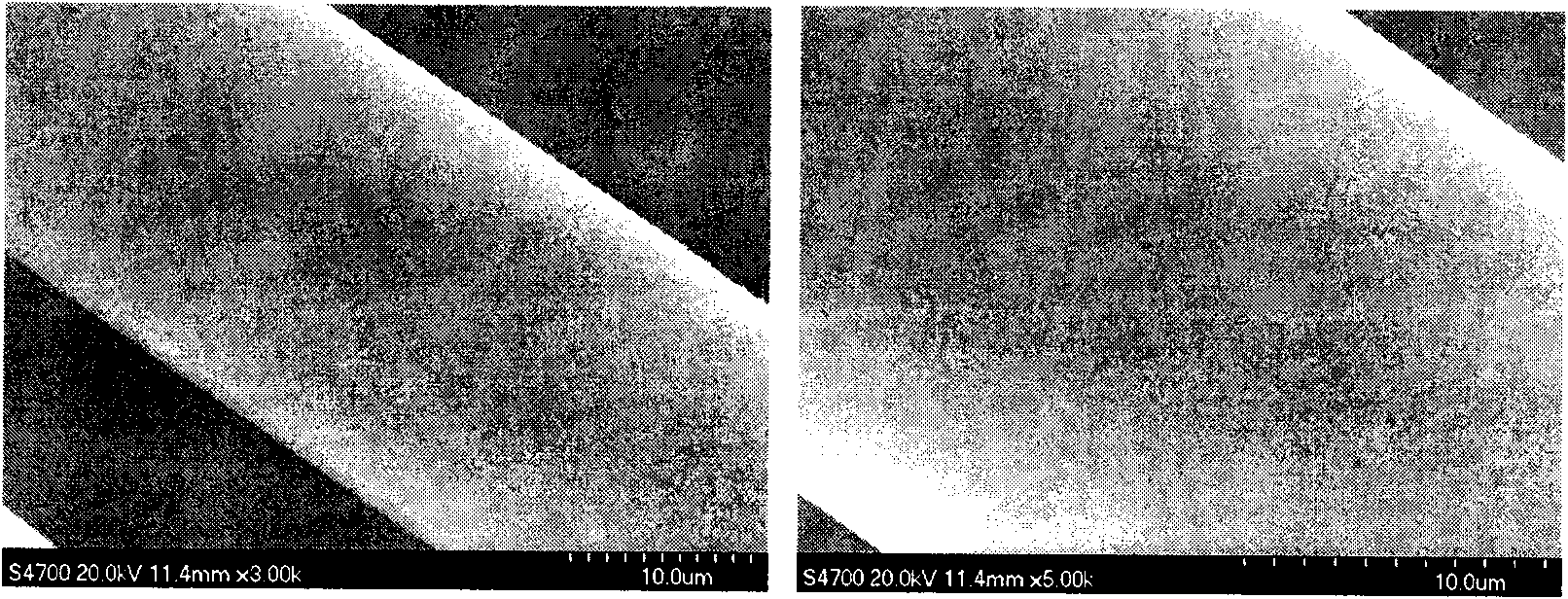

The invention provides a polyimide nano-fiber membrane with a crosslinked structure and preparation thereof, belonging to the technical field of polyimide nano-fiber membrane. Polyamide acid solution which is a prepolymer of polyimide is synthesized from diamine and a dibasic acid anhydride monomer. And polyimide nano-fiber membrane is prepared by the electrospinning technology. The polyimide nano-fiber membrane is then treated in alkali lye with PH of 8.5-10.5 for 10s-3h, washed and dried, which is then thermal-imidized through gradient heating up and cooled down to obtain polyimide nano-fiber membrane with the crosslinked structure. The polyimide nano-fiber membrane with the crosslinked structure prepared by the invention has the advantages of high strength, simple implementation process, easiness in processing and good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

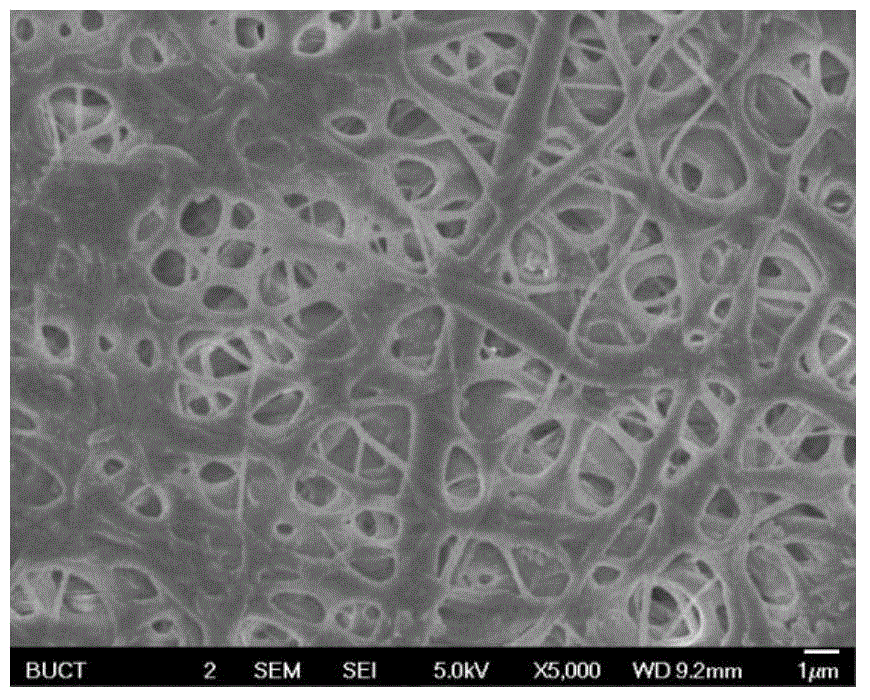

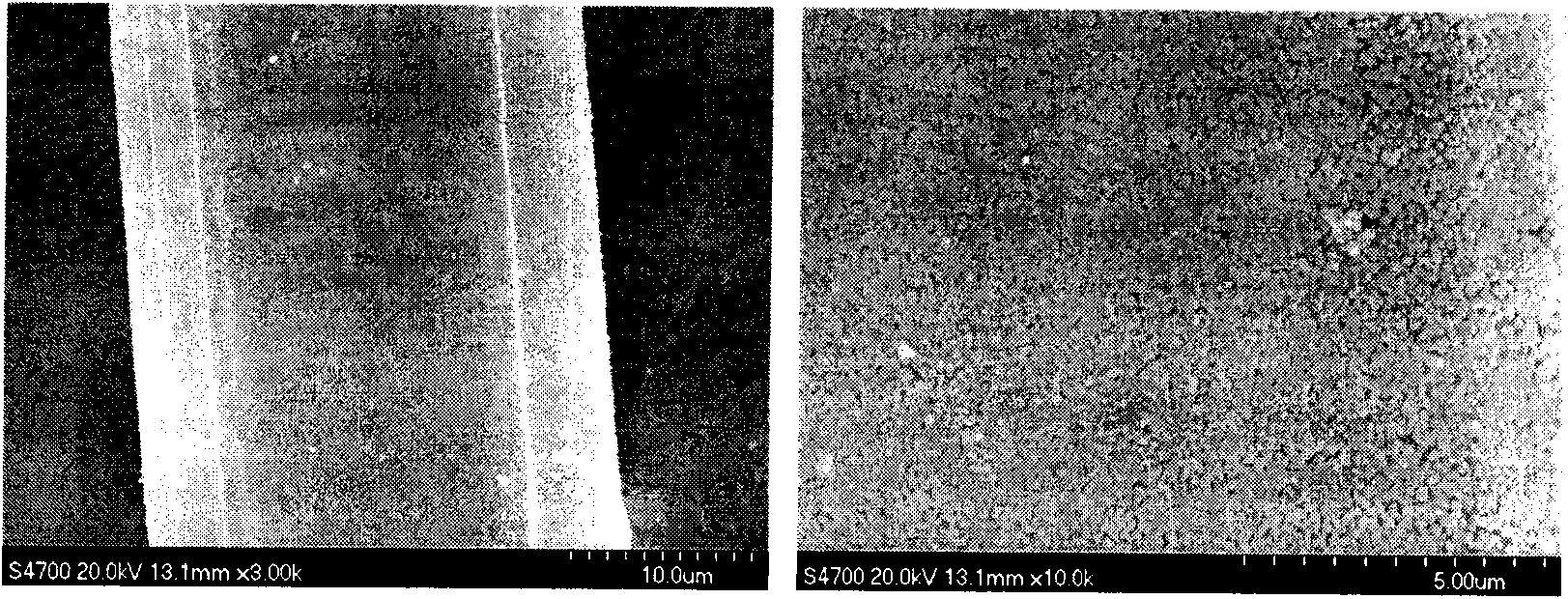

Polyimide fibrous membrane with crosslinking morphology and preparation method thereof

InactiveCN105040276AFiber destructionUnspoiledFilament/thread formingNon-woven fabricsElectrospinningPolyamide

The invention provides a polyimide fibrous membrane with crosslinking morphology and a preparation method thereof. Binary acid anhydride and diamine are adopted to perform solution condensation polymerization, so as to prepare a precursor of polyimide, i.e. polyamide acid; then a polyamide acid fibrous membrane is prepared by electrostatic spinning. The polyamide acid fibrous membrane is pretreated, and is heated to 200 to 250 DEG C, so as to obtain a partially imidized fibrous membrane, afterwards the partially imidized fibrous membrane is immersed into a soluble solvent of the polyamide acid for performing slightly soluble crosslinking treatment, is dried, and is subjected to high temperature thermal imidization so as to obtain the polyimide fibrous membrane with the crosslinking morphology. The prepared polyimide fibrous membrane has a crosslinking structure, the mechanical property is greatly improved, the pore structure is adjustable, crosslinking degree and pore structure distribution are adjusted by changing pretreatment temperature and solvent treatment time, the preparation process is simple, the process is easy to form, and the industrialized application prospect is very good.

Owner:北京凯越嘉诚科技发展有限公司

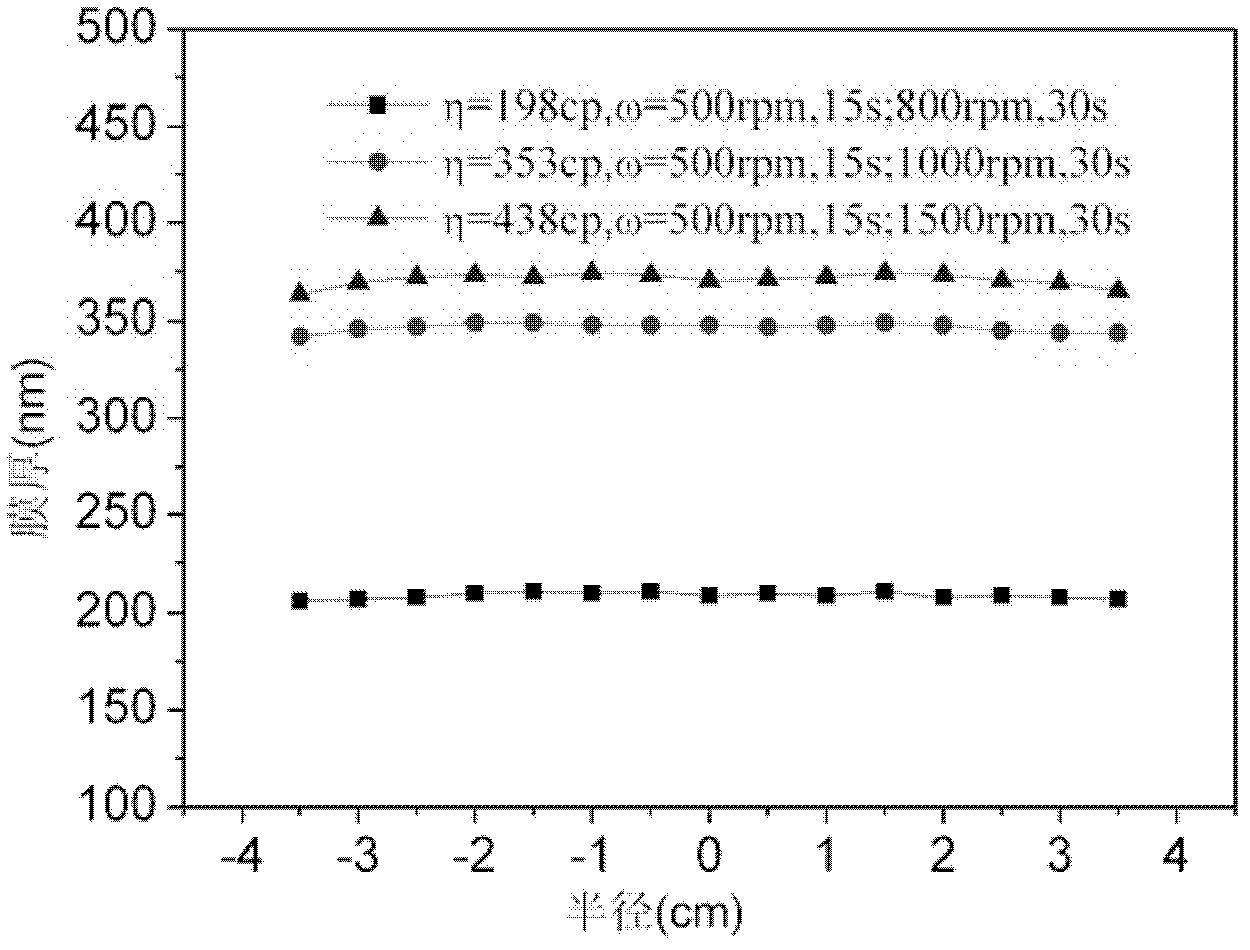

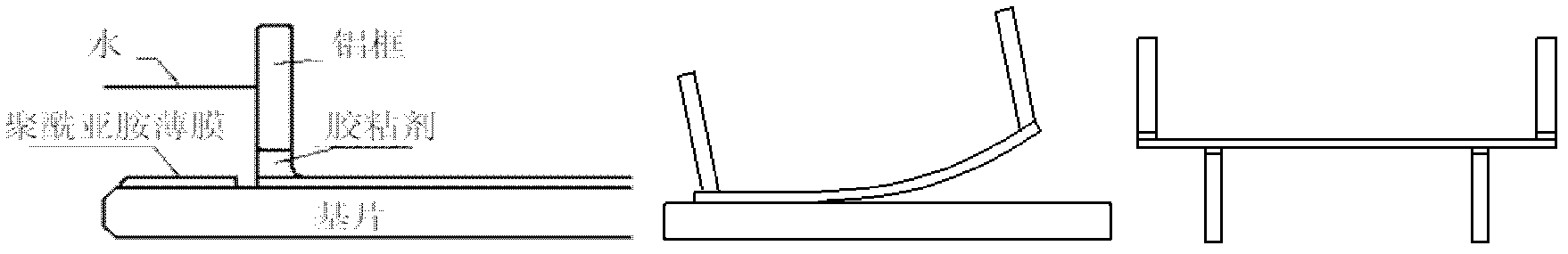

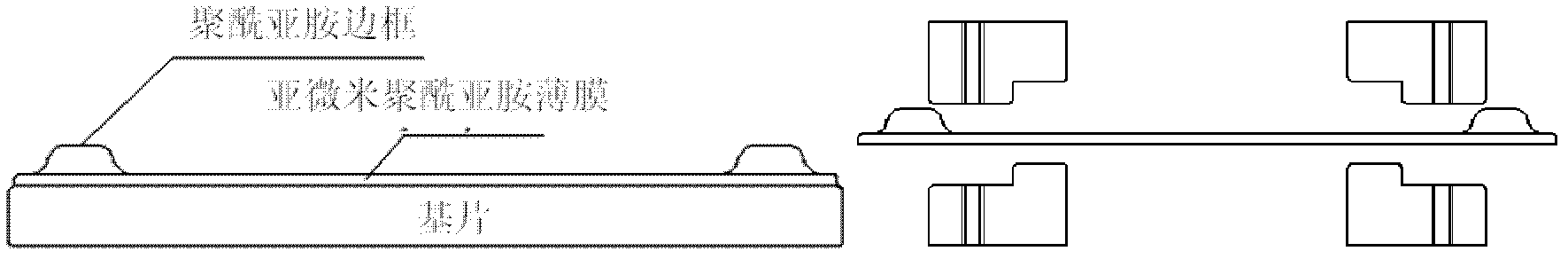

Method for preparing submicron polyimide self-supporting film by adopting spin-coating method

A method for preparing a submicron polyimide self-supporting film by adopting a spin-coating method belongs to the technical field of polyimide self-supporting films. The method comprises the following steps: firstly, preparing a polyamic acid solution, diluting and filtering; preparing a submicron polyamide acid film by adopting the spin-coating method and preliminary drying; secondly, coating the polyamic acid solution with the high solid content on the edge of the submicron polyamide acid film and homogenizing; carrying out thermal treatment and finishing an imidization process; placing a polyimide film with a substrate in a hot mixed solution of deionized water and alcohol; after a period of time, slightly tilting an edge thick film area by using a surgical knife along the edge of the substrate; clamping the thick film area by using tweezers and gradually removing the film from the substrate from the outside to the inside; and drying in air to obtain the polyimide self-supporting film. The film prepared by the method disclosed by the invention has the characteristics of uniformity in thickness distribution, large area, low surface roughness and the like. The method is simple in preparation process and is high in finished product rate.

Owner:BEIJING UNIV OF CHEM TECH +1

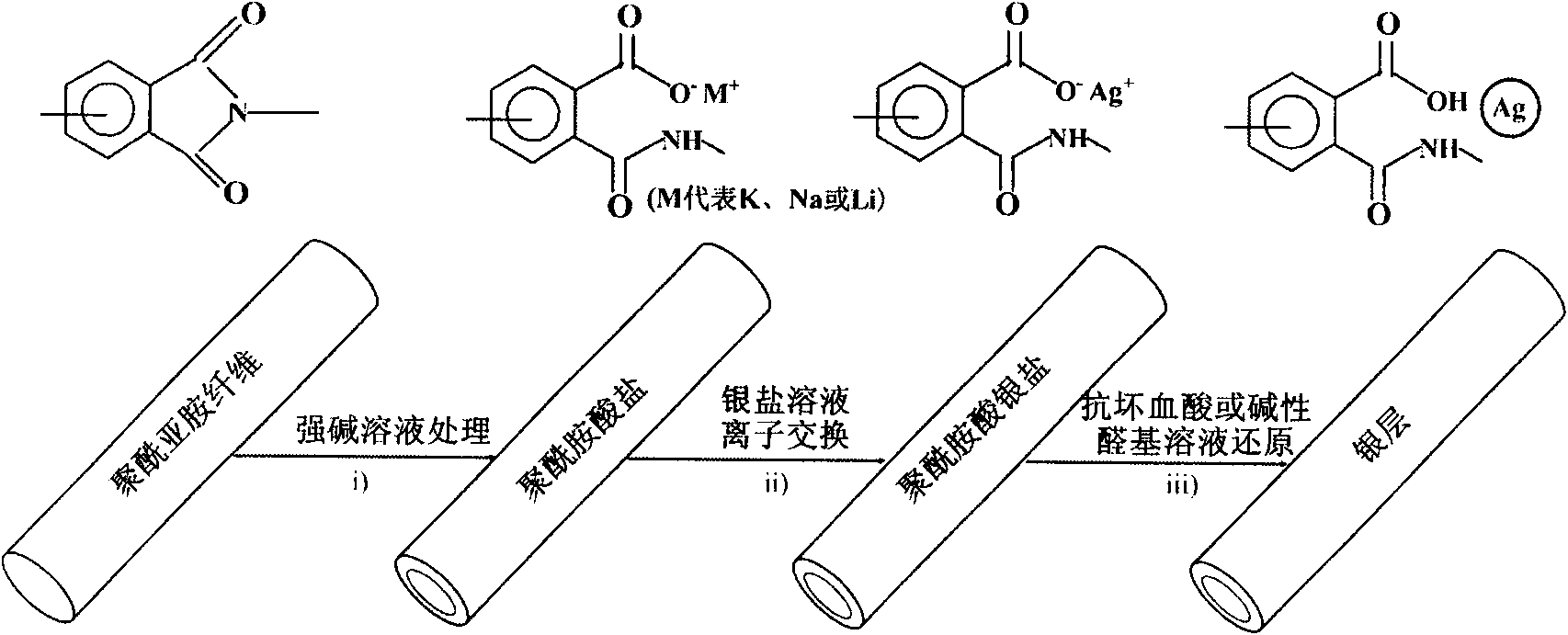

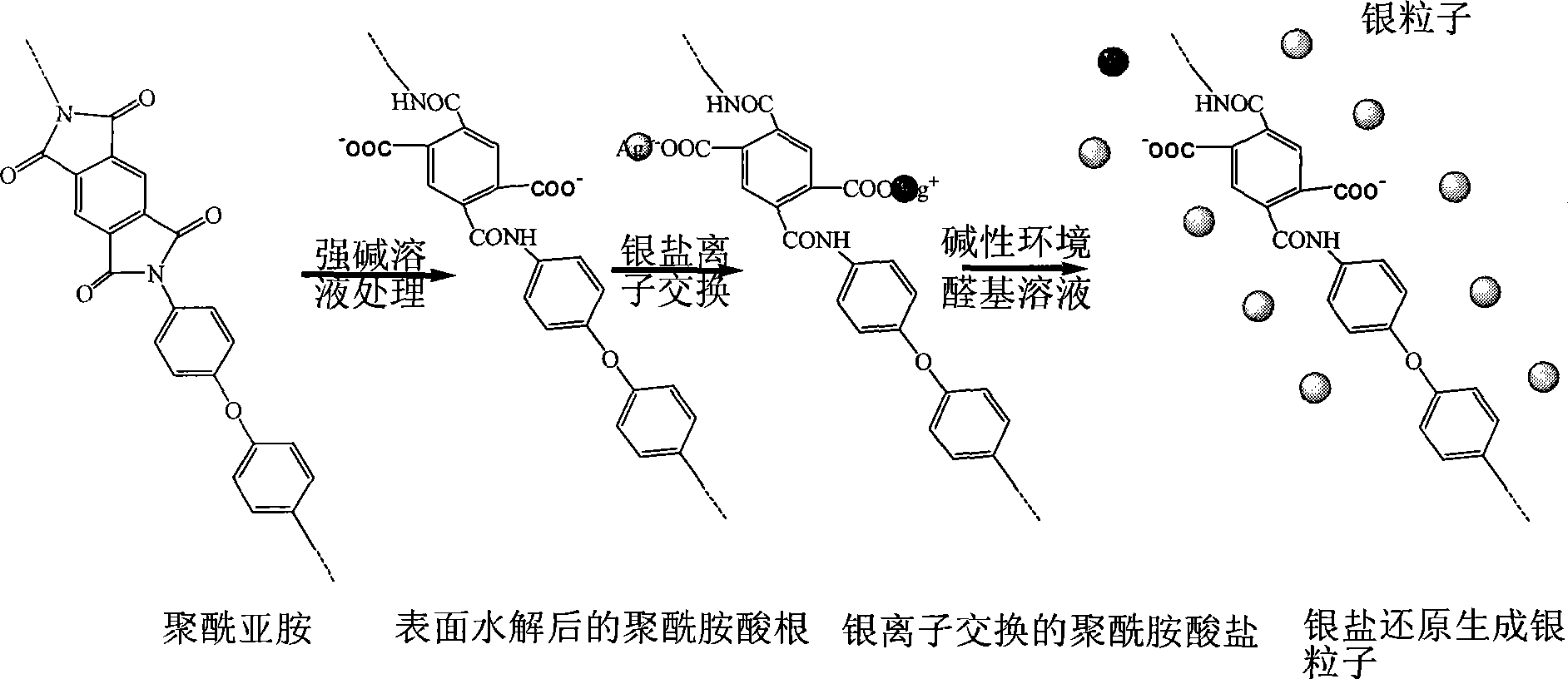

Method for preparing polyimide/silver composite conductive fiber

The invention relates to a method for preparing polyimide / silver composite conductive fiber, comprising: after removing surface impurities by ultrasonic treatment, soaking finished product polyimide fiber into alkaline solution, and leading polyimide on the surface layer of the fiber to open ring and hydrolyze to generate polyamide salt; then, soaking the polyamide salt into soluble silver salt water solution for ion exchange to form polyamic acid silver salt; finally, soaking the fiber with the polyamic acid silver salt on the surface into ascorbic acid or alkaline water solution containing aldehyde group, leading silver ion in an etch layer to be reduced and gathered on the surface, and obtaining the polyimide / silver composite conductive fiber. The method provided by the invention is simple and convenient for operation, non-toxic, free from pollution, low in cost and easy for industrialization; furthermore, the prepared composite conductive fiber not only maintains the mechanical property of matrix polyimide, but also has good electric conduction property.

Owner:BEIJING UNIV OF CHEM TECH

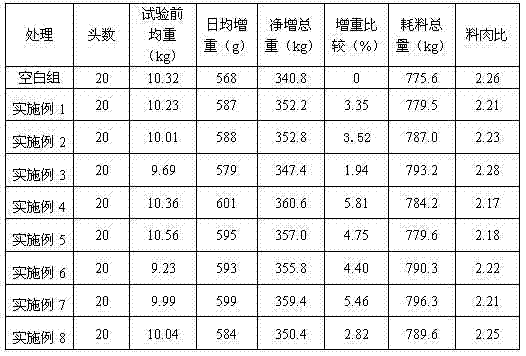

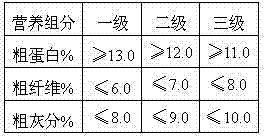

Pig feed and producing method thereof

InactiveCN104222693AWide variety of sourcesLow priceFood processingAnimal feeding stuffSocial benefitsNutrition

The invention discloses a pig feed and a producing method thereof. The pig feed is composed of the following raw materials by weight: 20-35 parts of fresh filter mud, 5-10 parts of molasses, 10-15 parts of manioc waste, 15-20 parts of rice bran and 0.2-1 part of trace elements. The method includes first fermenting the manioc waste under the effects of saccharifying enzyme, papain and fiber clastic enzyme, then drying the components, breaking the components to the regulated meshes and mixing the components, or conducting pelleting and then evenly mixing the components to obtain powder or particle products of the pig feed. The pig feed is good in palatability, balanced in nutrition, lower in price relative to the traditional pig feed, the pig raising cost is greatly reduced, and the economical benefit and the social benefit are greatly improved.

Owner:来光业

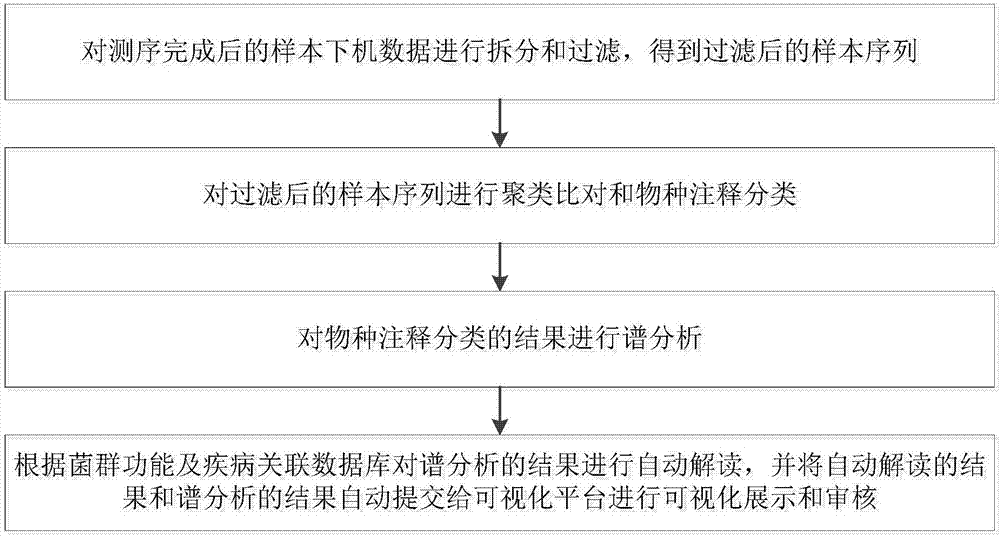

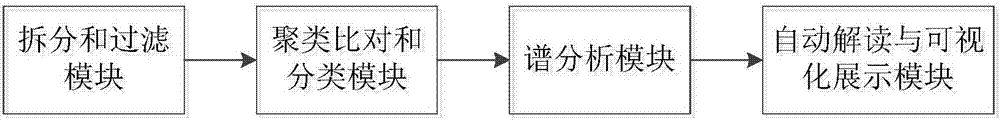

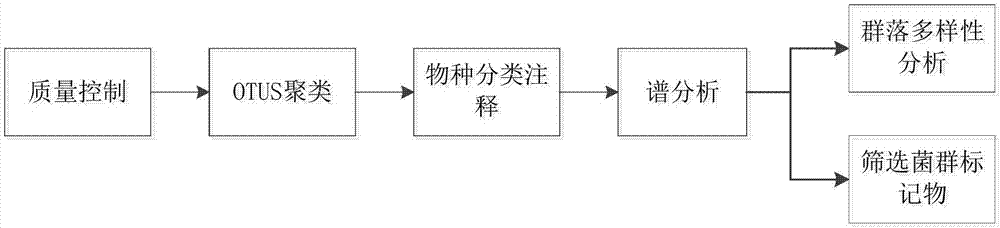

Enteric microorganism information analysis method and system

ActiveCN107463800AIntuitive handlingVisual reviewData visualisationBiostatisticsDiseaseInformation analysis

The invention discloses an enteric microorganism information analysis method and system. The method comprises the steps of splitting and filtering offline sample data after sequencing to obtain filtered sample sequences; performing clustering comparison and species annotation classification on the filtered sample sequences; performing spectral analysis on a species annotation classification result; and performing automatic interpretation on a spectral analysis result according to flora functions and a disease correlation database, and automatically submitting an automatic interpretation result and the spectral analysis result to a visual platform for performing visual display and auditing. The system comprises a splitting and filtering module, a clustering comparison and classification module, a spectral analysis module, and an automatic interpretation and visual display module. The method and the system have the advantages of convenient process and batch operations, small artificial interpretation workload, intuitiveness and convenience, and can be widely applied to the field of biological information analysis.

Owner:CAPITALBIO GENOMICS

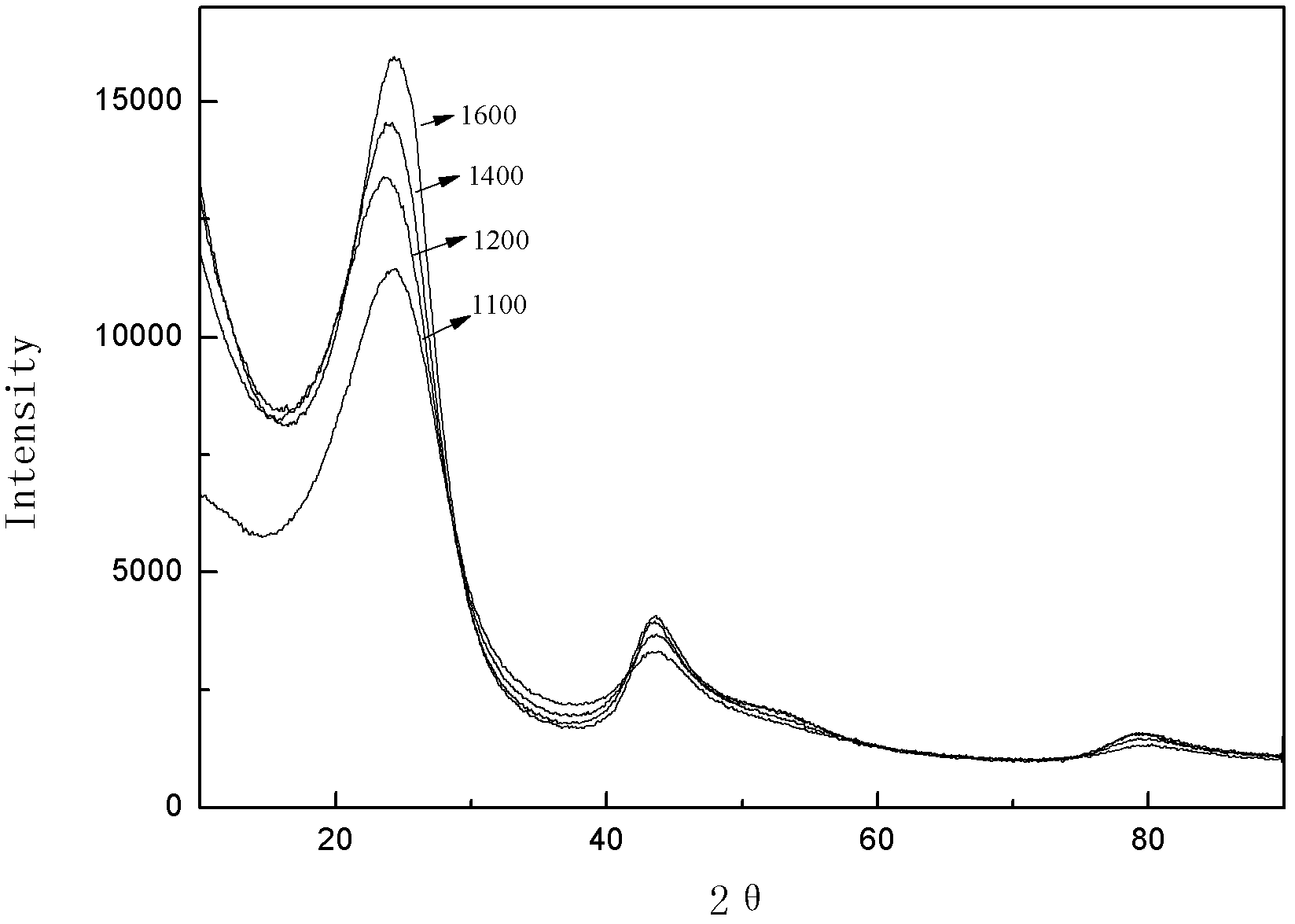

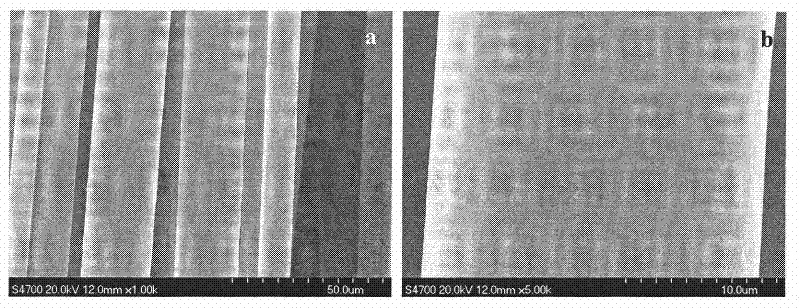

Polyimide-based carbon fiber and preparation method thereof

ActiveCN102605477AExpand raw materialsImprove compactnessMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberPolymer science

The invention discloses a polyimide-based carbon fiber and a preparation method thereof, and belongs to the technical field of carbon fibers. The method comprises the following steps of: synthesizing a polyamide acid solution by adopting diamine and dianhydride monomers, and then preparing polyimide fiber; fixing the polyimide fiber in a vacuum tube furnace, and applying a force along the axial direction of the vacuum tube furnace so that the fiber is in a drawn state in a heat treatment process; performing gradient heating under the protection of N2 at the heating rate of 2 to 10 DEG C per minute for carbonization treatment till the final temperature is 1000 to 1600 DEG C, and preserving the heat for 10 to 60 minutes at the final temperature; and performing natural cooling, and thus obtaining the polyimide-based carbon fiber, wherein the polyamide acid solution is prepared by mixed polycondensation reaction of one diamine and one dianhydride, or prepared by copolycondensation of random one or more diamines and random more or one dianhydride, or prepared by blending random more mixed polycondensation or copolycondensation polyimides. The obtained polyimide-based carbon fiber has good compactness, few defects, high carbon content and conductivity.

Owner:BEIJING UNIV OF CHEM TECH

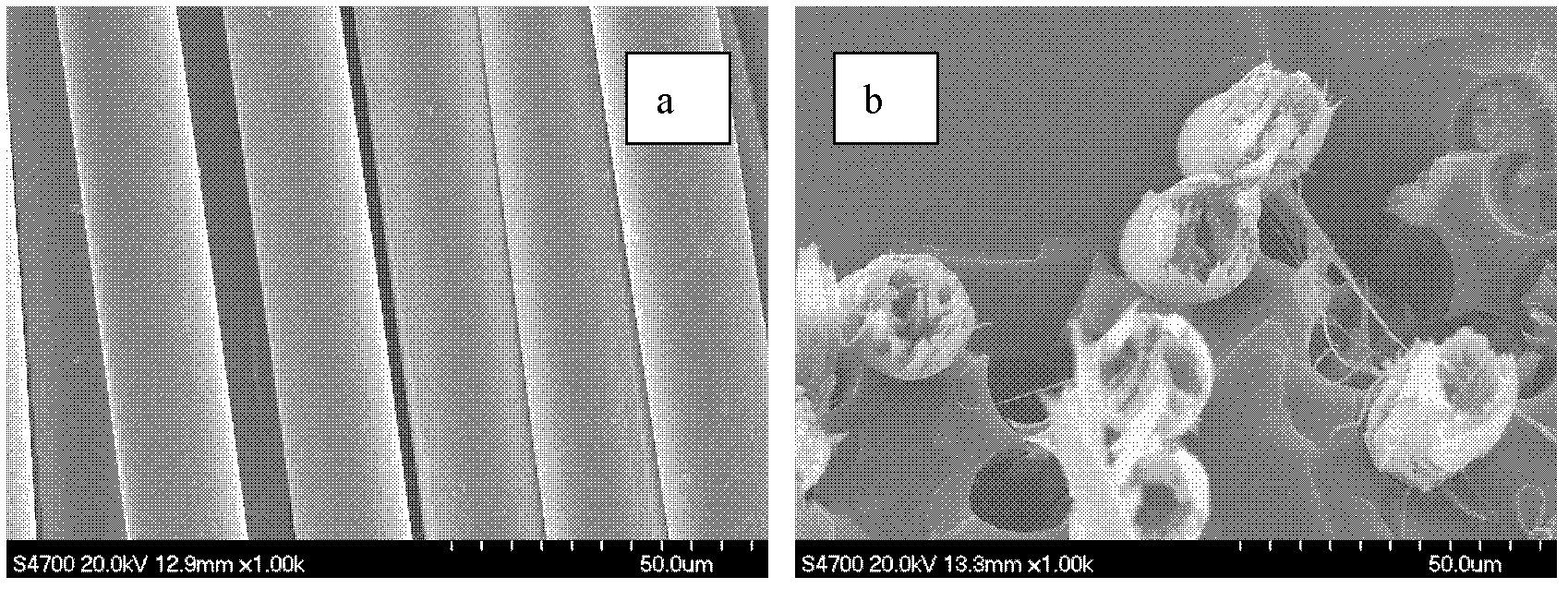

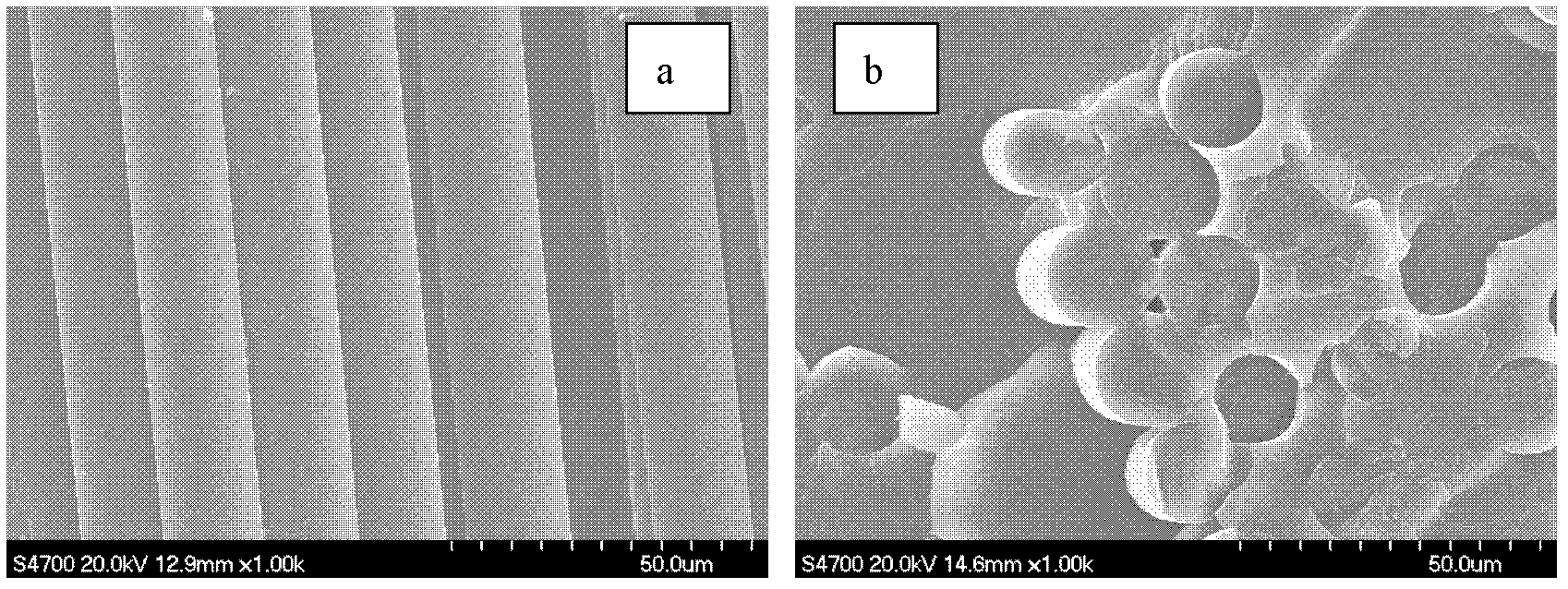

Polyimide/polyolefin complex fiber membrane with cross-linked structure and preparation method

InactiveCN104213333ALow costClosed cell temperature adjustableFilament/thread formingNon-woven fabricsPolymer sciencePolyolefin

The invention discloses a polyimide / polyolefin complex fiber membrane with a cross-linked structure and a preparation method. The preparation method comprises the following steps of adopting an electrospinning method to prepare a non-woven polyimide / polyolefin complex fiber membrane; carrying out controlled heating treatment to enable polyolefin fiber to be heated and melted slightly; forming melting welding points among polyimide ultrafine fibers to prepare the polyimide / polyolefin complex fiber membrane with the cross-linked structure. The cross-linked shape is formed, so that the mechanical property and the dimensional stability of the fiber membrane can be remarkably improved. The polyolefin is used, so that the cost of the complex fiber membrane is greatly reduced. In addition, the polyolefin fiber membrane can be pore-closed after being heated to a certain condition, so that the polyimide / polyolefin complex fiber membrane capable of realizing the pore close function at different temperature levels can be prepared through selecting polyolefin with different melting points. The complex fiber membrane has wide application prospect in the field of lithium-ion battery separators, and can meet the application requirement of current different lithium-ion batteries on microporous membranes with different pore close temperatures.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Polyimide fiber with kidney-shaped section and preparation method thereof

ActiveCN102560707AImprove production efficiencySimple preparation processSpinning solution filteringSpinning solution de-aeratingFiberConductor Coil

A polyimide fiber with kidney-shaped section and a preparation method thereof belong to the technical field of polyimide fibers. The preparation method includes: utilizing polyamide acid (PAA) solution synthesized by aromatic dianhydride and aromatic diamine to perform the wet spinning process by the aid of circular spinneret holes, adjusting spinning conditions including spinneret speed, composition, proportion and temperature of coagulating bath, the length of hydrazine and the like to obtain a PAA as-formed fiber with kidney-shaped section, then washing and drying the PAA as-formed fiber, cyclizing and drafting the same at high temperature stage by stage, and winding and the like, finally obtaining the polyimide (PI) fiber with the kidney-shaped section. The preparation method of the polyimide fiber with the kidney-shaped section has the advantages of simplicity in spinneret hole design and processing, easiness in control of spinning process, high preparation efficiency, low cost for raw materials, low energy consumption and the like and can be used for large-scale industrialized production.

Owner:BEIJING UNIV OF CHEM TECH

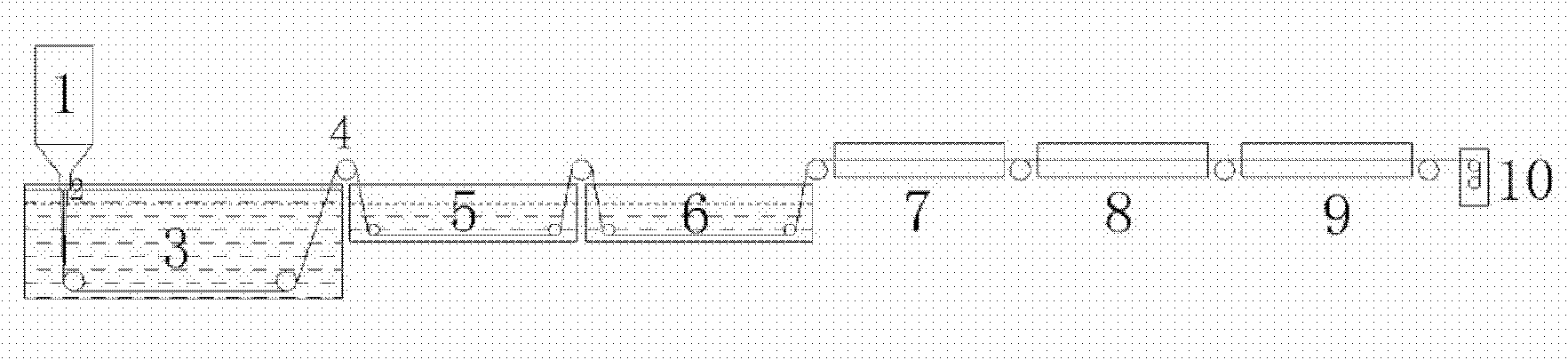

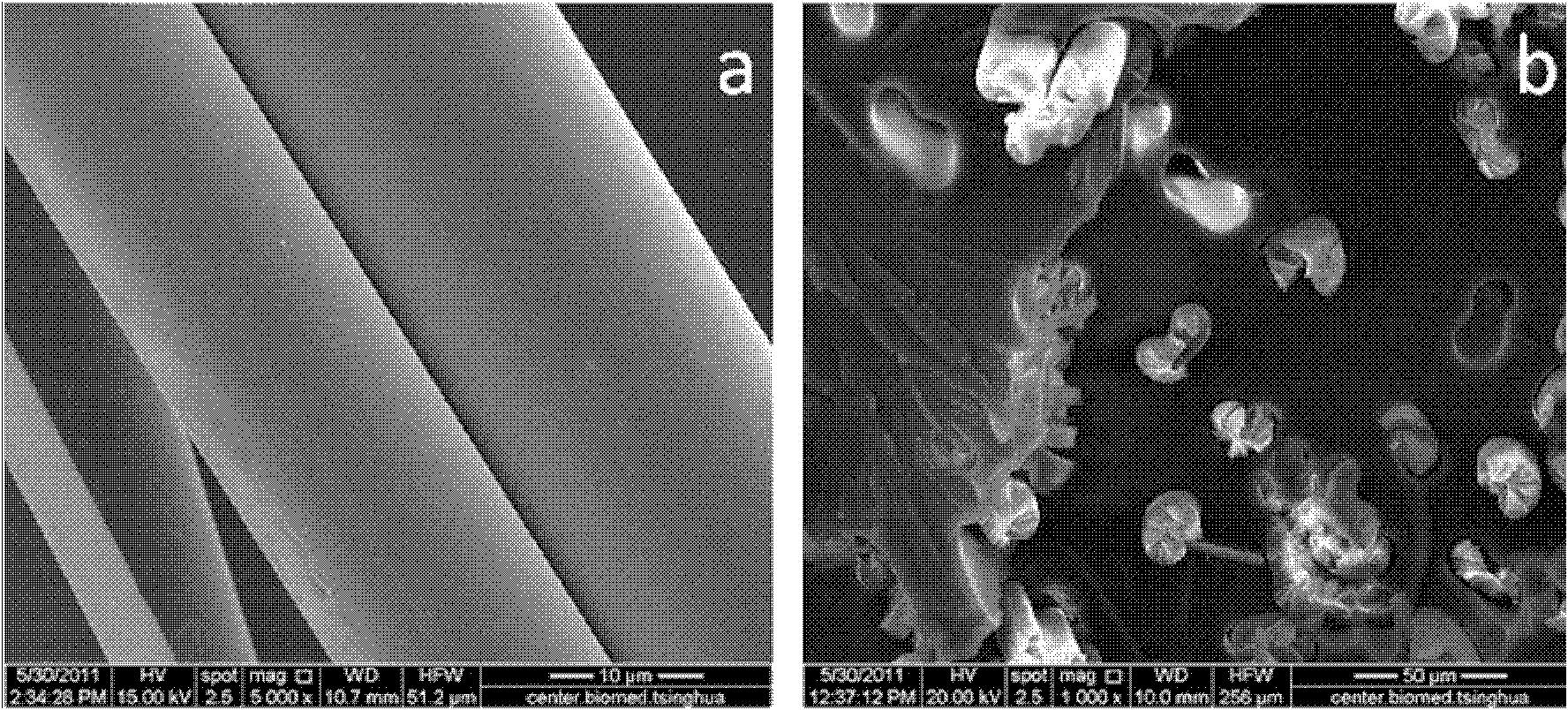

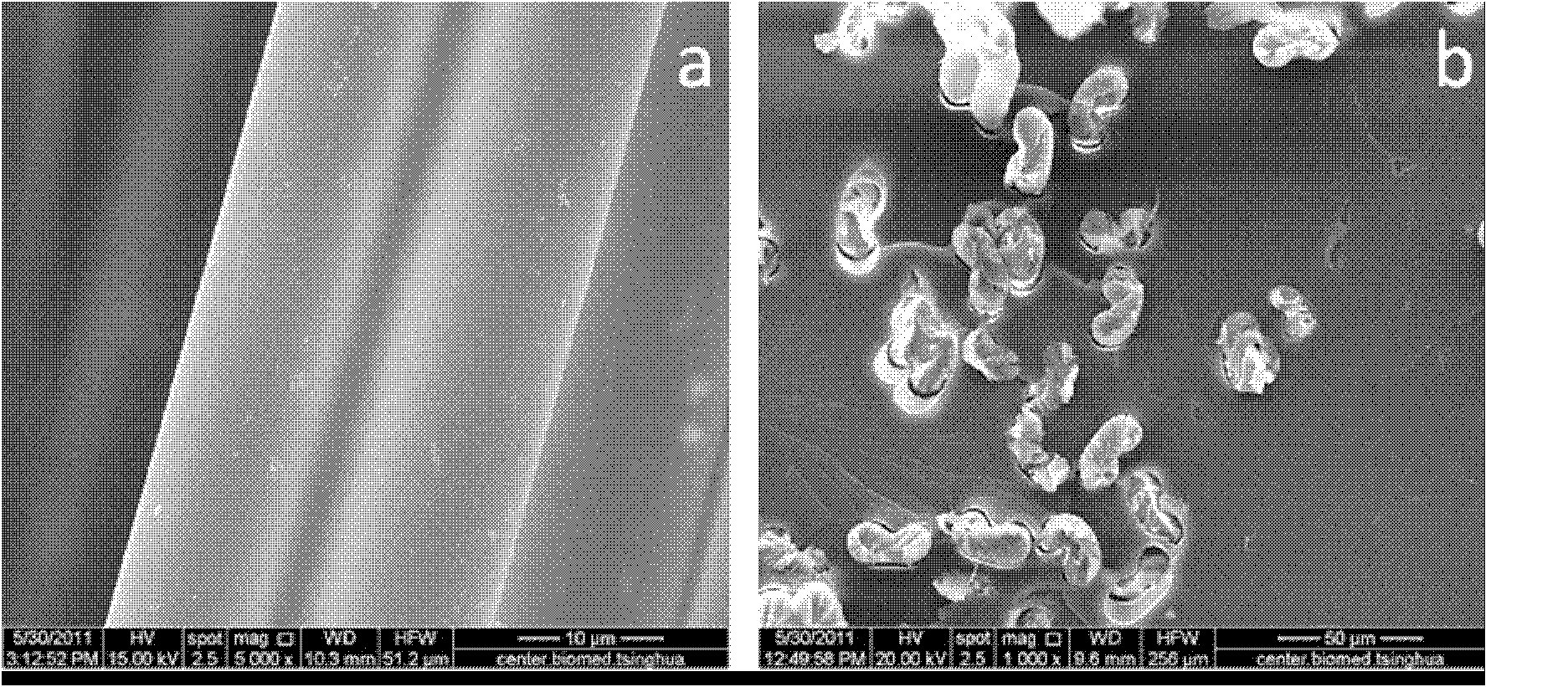

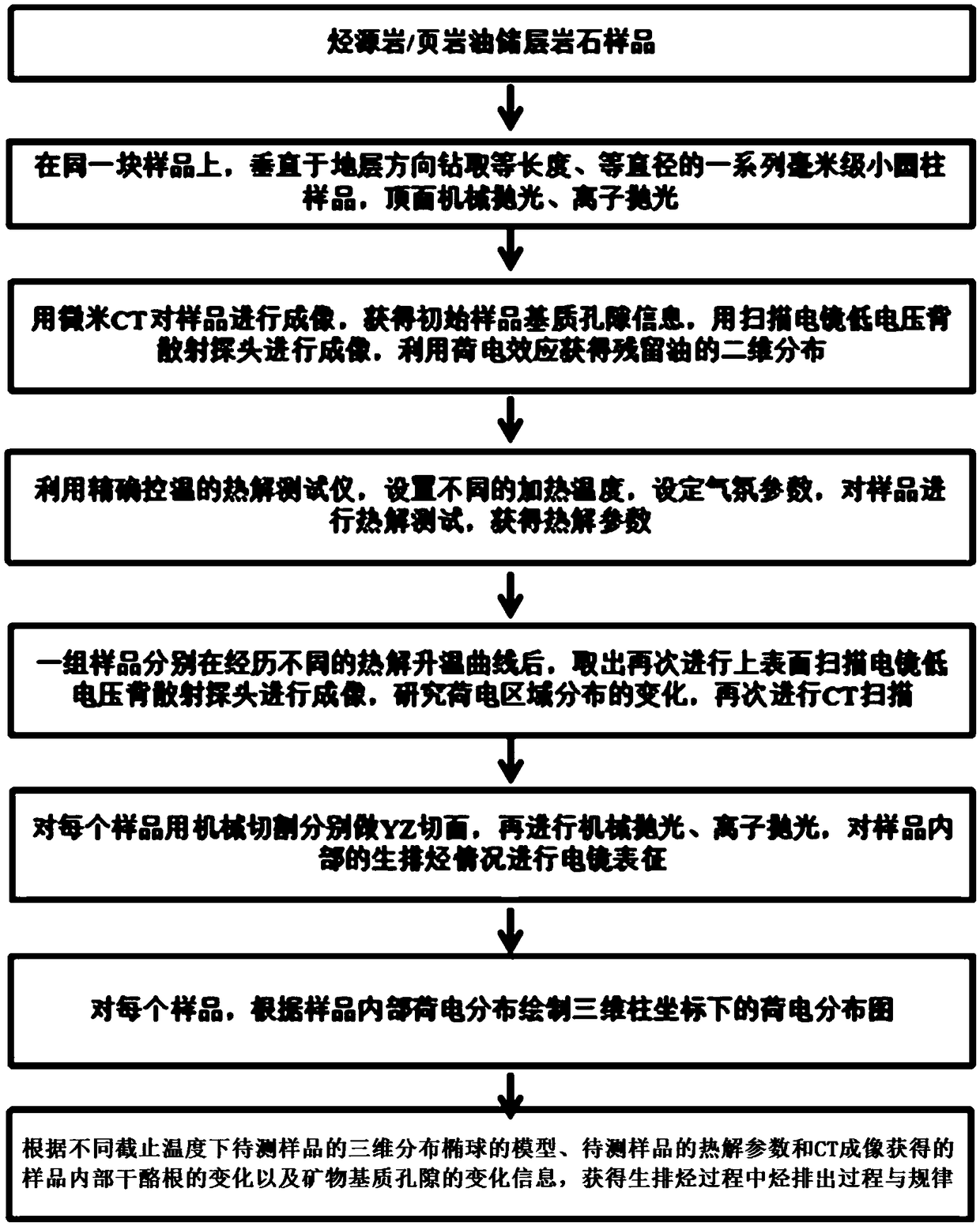

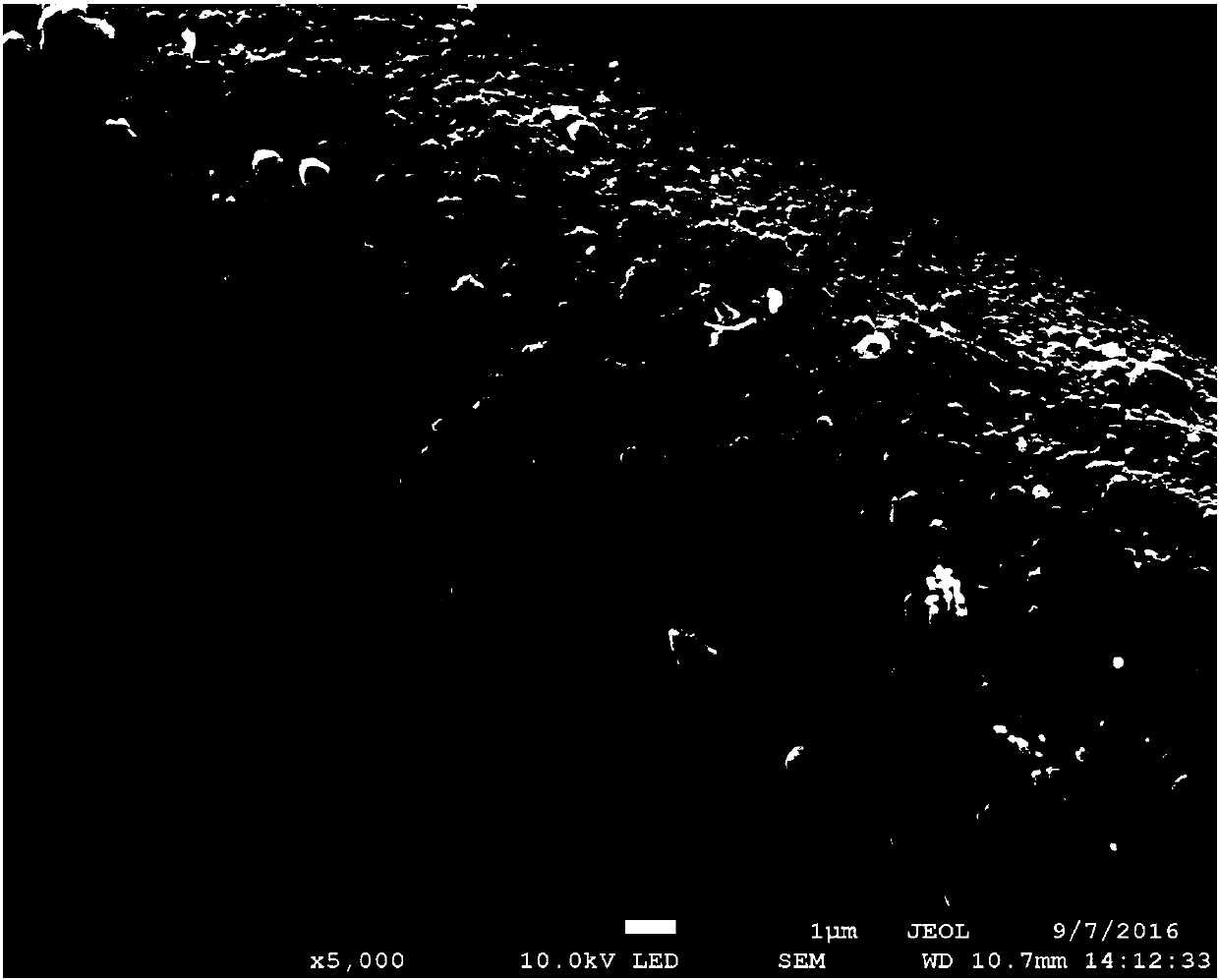

Hydrocarbon generation and expulsion characterization and evaluation method of source rock pyrolysis/shale oil in-situ modification

ActiveCN108982194AObtain quantitative informationSimplify the analysis processMaterial analysis using wave/particle radiationPreparing sample for investigationElectricityScanning tunneling microscope

The invention provides a hydrocarbon generation and expulsion characterization and evaluation method of source rock pyrolysis / shale oil in-situ modification. The hydrocarbon generation and expulsion characterization and evaluation method comprises the following steps of collecting source rock / shale oil reservoir rock samples; drilling multiple cylinder samples from one sample; performing polishingtreatment to obtain samples to be detected; performing CT imaging and scanning electron microscope imaging on the top surfaces of all the samples to be detected; performing pyrolysis on all the samples to be detected; performing CT imaging and scanning electron microscope imaging on all the samples to be detected after pyrolysis again, and comparing two change information; and according to acquired change information in two-dimensional distribution of residual oil, selecting samples, the surfaces of which do not have obvious charging phenomenon, to be detected after pyrolysis in scanning electron microscope imaging for further splitting as YZ sections, using scanning electron microscope imaging to acquire two-dimensional distribution information of residual oil of the YZ sections, correspondingly establishing three-dimensional distribution ellipsoids of the residual oil, and finally, combining pyrolysis parameters and CT imaging information of the samples to be detected to acquire hydrocarbon generation and expulsion characterizations. The hydrocarbon generation and expulsion characterization and evaluation method provided by the invention is simple and effective.

Owner:PETROCHINA CO LTD

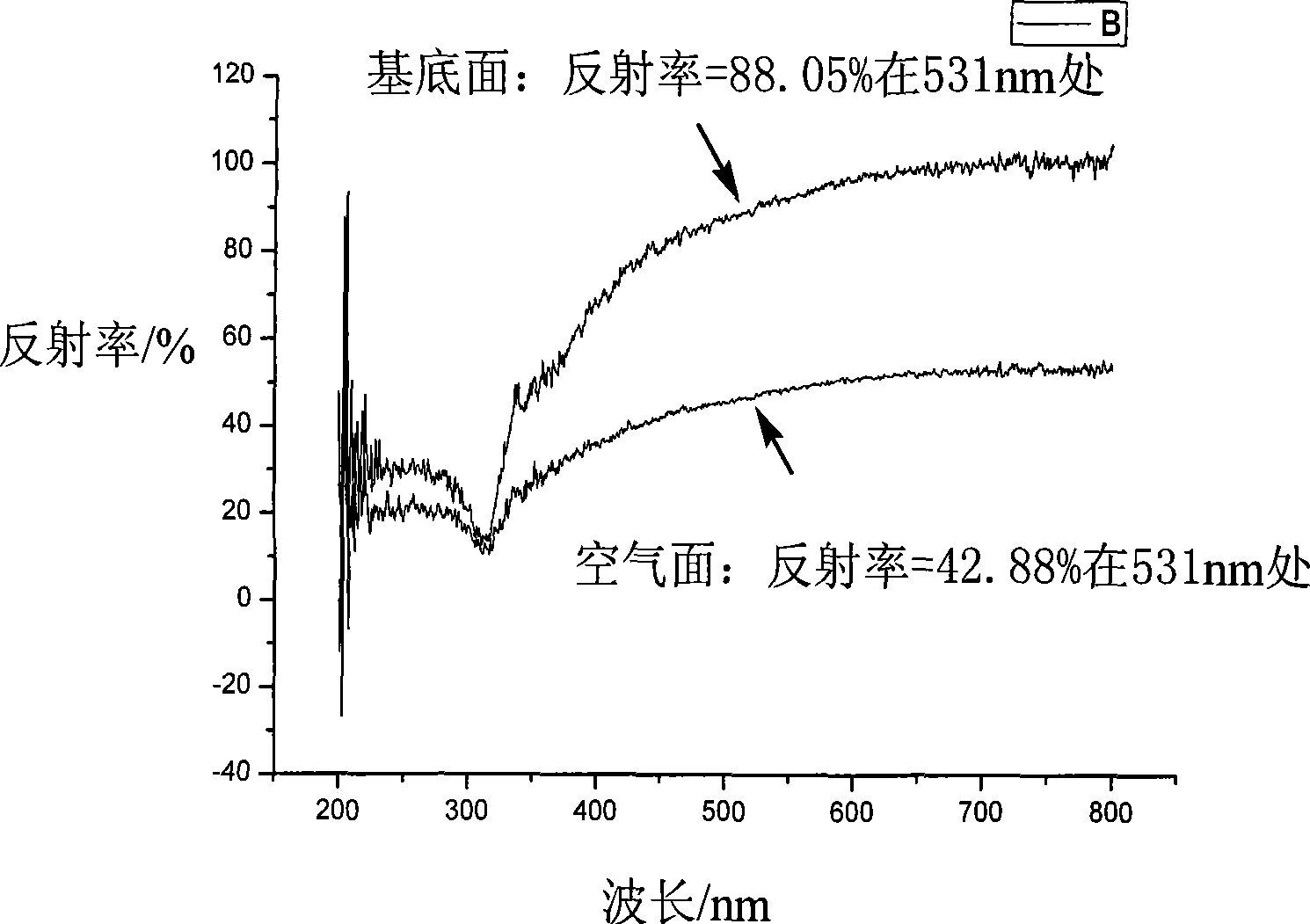

Method for preparing two-sided polyimide / silver compound film

Owner:BEIJING UNIV OF CHEM TECH

Method for reclaiming aluminum powder from composite propellant

InactiveCN102373340ALow priceDo not use muchProcess efficiency improvementRecovery methodOrganic solvent

The invention discloses a method for reclaiming aluminum powder from a composite propellant, and belongs to the field of manufacturing of composite solid propellants. The reclaiming method comprises the following steps of: removing water in an organic solvent soaking or heating mode, removing organic substances on the surface of the aluminum powder by using a nitric acid solution, and separating the matrix from the aluminum powder by using a sodium alcoholate solution. According to the step-by-step solvent method, the adhesive matrix-polyurethane of a composite solid propellant in which the ammonium perchlorate is reclaimed is degraded, and the matrix and the aluminum powder are separated, so that the aluminum powder is successfully separated and reclaimed and the recovery rate is high and can reach over 99.5 percent; and the method is easy to implement, high in recovery rate and easy in flow process, and has good industrialized prospect.

Owner:BEIJING UNIV OF CHEM TECH +1

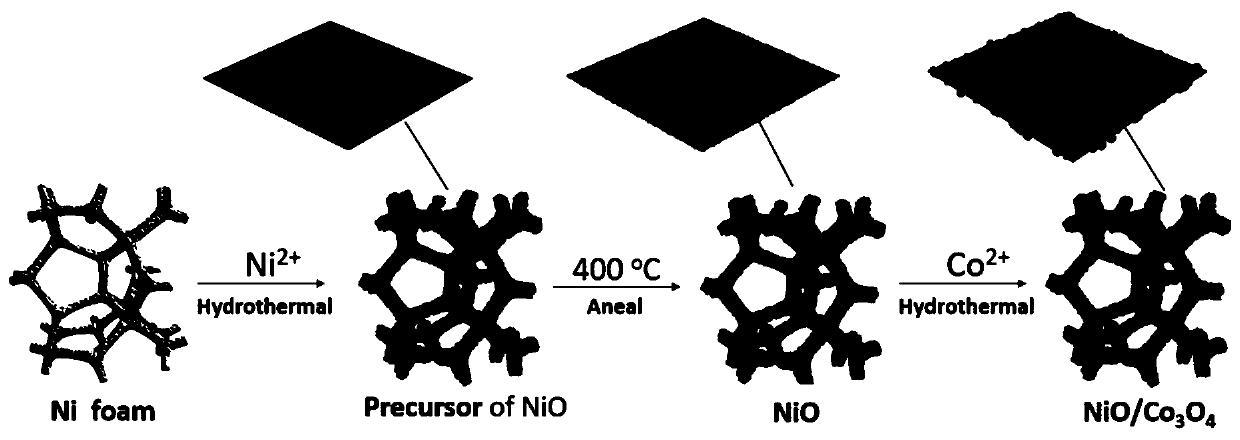

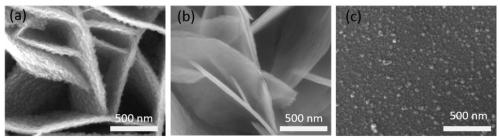

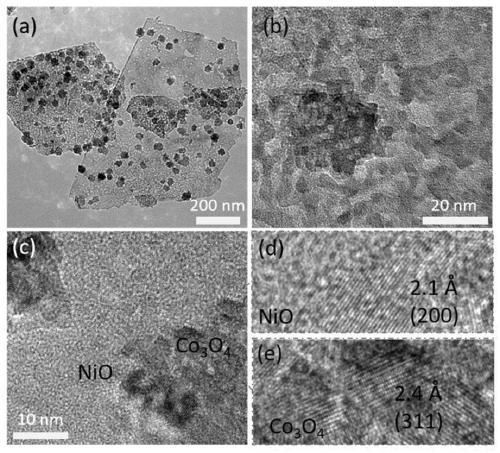

Preparation method and application of NiO/Co3O4

ActiveCN111195518AHigh activityShorten the electron transport pathMetal/metal-oxides/metal-hydroxide catalystsElectrodesAmmonium fluorideCobalt acetate

The invention discloses a preparation method of a nickel oxide-cobaltosic oxide (NiO / Co3O4) composite electrode material based on foamed nickel growth. The process comprises the following steps of: firstly, preparing a precursor of nickel oxide through a hydrothermal method by taking nickel nitrate and urea as raw materials, ammonium fluoride as a morphology control agent and foamed nickel as a substrate, carrying out low-temperature annealing on the precursor in air to obtain pure NiO, and then taking the nickel oxide as a substrate material, adding a cobalt acetate solution and ammonia water, and carrying out a second-step hydrothermal reaction to obtain the NiO / Co3O4 two-phase composite electrocatalyst material growing on a foamed nickel substrate. A plurality of interfaces and defectsbeneficial to catalytic reaction appear in the material, and compared with a single-phase catalyst, the catalytic activity is greatly improved. And meanwhile, due to the use of the foamed nickel substrate, the addition of a conductive agent and an adhesive in the electrocatalysis process can be avoided, the implementation process of the catalytic reaction is simplified, and the electrode impedanceis also reduced.

Owner:LANZHOU UNIVERSITY

Method for recovering ferrocene derivatives and ammonium perchlorate from composite solid propellant

The invention provides a method for recovering ferrocene derivatives and ammonium perchlorate from a composite solid propellant, which belongs to the field of fabrication of composite solid propellants. The method comprises an immersion step of immersing the composite solid propellant in dichloromethane, 1,2-dichloroethanes or N,N-dimethylacetamide, a distillation step of distilling an organic solvent so as to obtain a crude product of ferrocene derivatives, a purification step of purifying the crude product of ferrocene derivatives through recrystallization or sublimation, an extraction step of using a saturated solution of ammonium perchlorate as an extractant and a recrystallization step for obtaining ammonium perchlorate. According to the invention, the method of organic solvents is utilized in the invention for separation and recovery the active components of ammonium perchlorate and ferrocene derivatives, and a high recovery rate is achieved; implementation process of the invention is simple, and the method is easy to form a flow and has a good industrial prospect.

Owner:BEIJING UNIV OF CHEM TECH +1

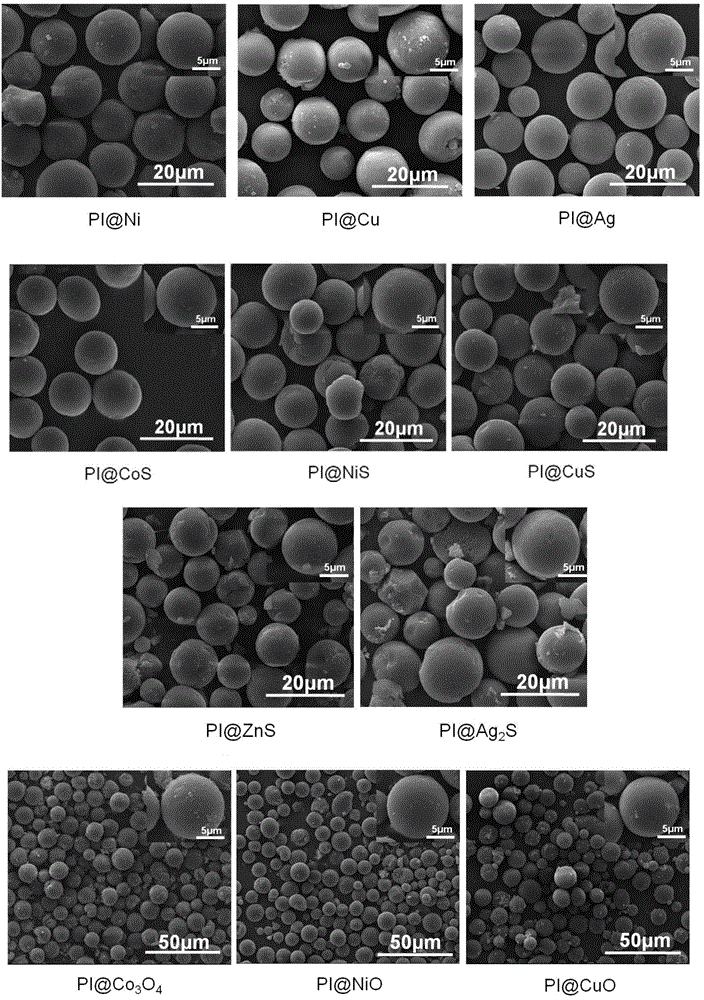

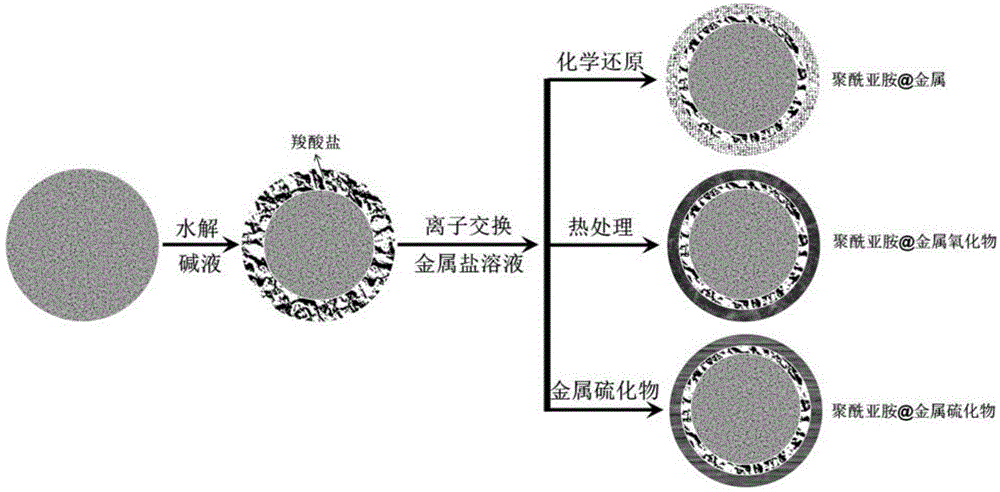

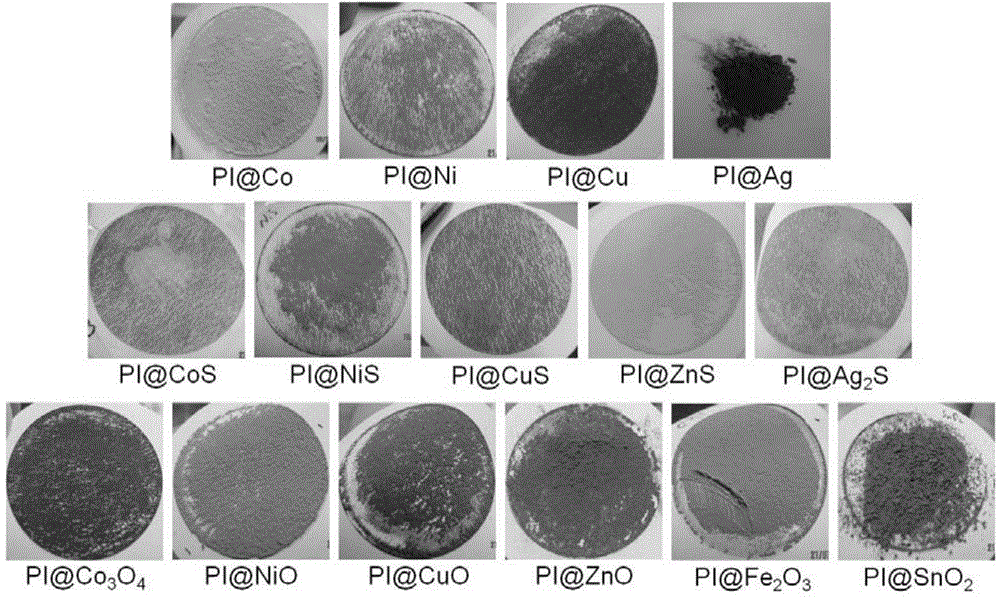

Preparation method for core-shell type polyimide@metal/metal oxide/metal sulfide composite microballoons

InactiveCN104587919AImprove interfacial adhesionLow densityMicroballoon preparationMicrocapsule preparationMicrosphereIon exchange

A preparation method for core-shell type polyimide@metal / metal oxide / metal sulfide composite microballoons, and belongs to the field of microballoon surface metallization. The preparation method comprises: immersing a polyimide microballoon into a strong alkali solution, so as to enable the imide bond at the microballoon surface to be hydrolyzed to form an amido group and a carboxylate; then immersing in a solution of a soluble metal salt, so as to obtain a metal salt compound of polyamide acid through in-situ ion exchange; immersing the polyimide microballoon containing the metal ion at the surface into a reducing agent solution, so as to obtain a core-shell type polyimide@metal composite microballoon; or performing heat treatment on the polyimide microballoon containing the metal ion at the surface in air, so as to obtain a core-shell type polyimide@metal oxide composite microballoon; or immersing the polyimide microballoon containing the metal ion at the surface into a solution of a soluble sulfide, so as to obtain a core-shell type polyimide@metal sulfide composite microballoon. The preparation method is simple in execution process, easy to processize and good in industrialization prospect.

Owner:BEIJING UNIV OF CHEM TECH

Miniature compressed tea processing method

InactiveCN105394232ASimple production processEasy to cleanPre-extraction tea treatmentFlavorFood grade

A miniature compressed tea processing method relates to the technical field of tea processing, and the processing steps are as follows: adjusting of water content of primary tea, compressing and forming, pre-packaging, sterilizing, eurotium cristatum culture and flavor increasing and drying. Compared with a traditional compressed tea process, the miniature compressed tea processing method is characterized in that: before the compressing of the compressed tea, steaming is not needed, after the forming, a food grade material is used for wrapping for high temperature and high pressure sterilizing, on the one hand contamination of other microorganisms can be effectively inhibited, on the other hand independent microenvironment for mass propagation of eurotium cristatum is provided for each piece of the compressed tea, and the stability of the mass propagation of the eurotium cristatum is improved.

Owner:XIANYANG JINGWEI EIGHT TEA CO LTD

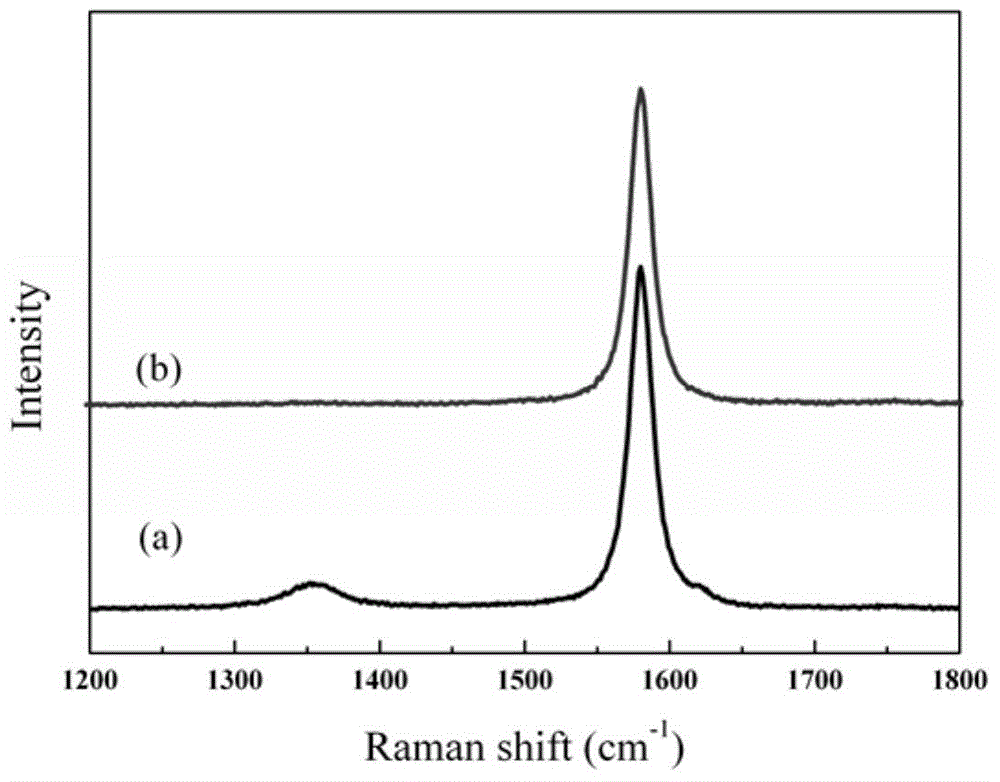

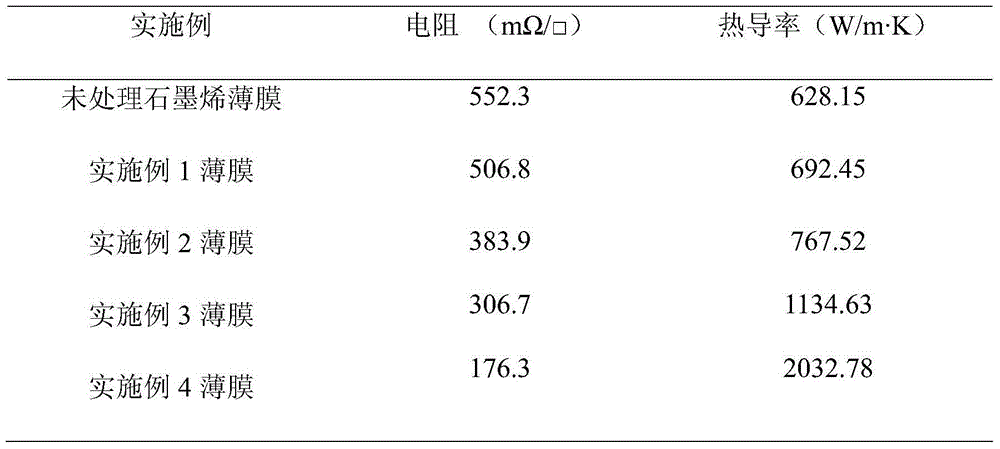

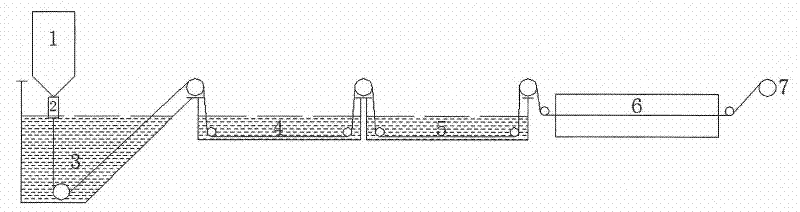

Graphene film preparation method

The invention relates to a graphene film preparation method, and belongs to the technical field of graphene films. The method comprises: uniformly spreading graphene or graphite sheet powder on a paper base, plastic-based film or steel plate being in a stationary or moving forward at a uniform speed, carrying out multi-roller rolling, pressing the powder into a film through mechanical force so as to prepare a graphene or graphite sheet film, fixing the pressed film into a graphite furnace in a coil or sheet manner, carrying out a high temperature treatment under the protection of an inert gas, and naturally cooling after completing the high temperature treatment so as to obtain the completely-graphitized graphene film. According to the present invention, on the basis of no loss of the film weight and no change of the film morphology and the film thickness, the graphene film with the complete structure is obtained through the high temperature treatment so as to effectively reduce the sheet resistance and substantially improve the thermal conductivity coefficient; and the method has characteristics of simple implementation process, easy process, no pollution, and good industrial prospects.

Owner:BEIJING UNIV OF CHEM TECH

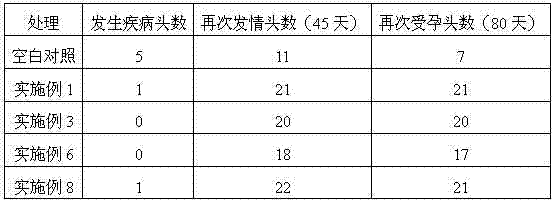

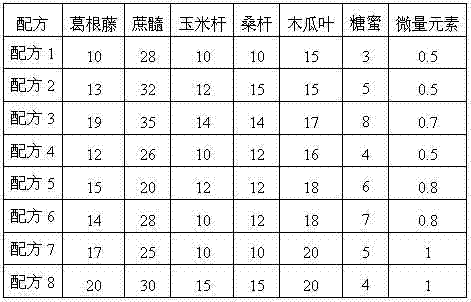

Cow feed and production method thereof

InactiveCN104222692AGood palatabilityNutritional balanceFood processingAnimal feeding stuffNutritionMilk production

The invention discloses cow feed and a production method thereof. The cow feed is composed of raw materials, by weight, of 10-20 parts of radix puerariae vine, 20-35 parts of bagasse pith, 10-15 parts of corn stalks, 10-15 parts of white mulberry stems, 15-20 parts of papaya leaves, 3-8 parts of molasses and 0.5-1 parts of trace elements. The production method includes the steps of drying all components, pulverizing all components to 60-80 meshes, adding 3-5% of lactic acid bacteria to bagasse pith, corn stalks, white mulberry stems and papaya leaves for fermentation, pulverizing or respectively granulating all components, and uniformly mixing to obtain the cow feed. The cow feed is safe, good in palatability, nutritionally balanced and reasonable in component matching, facilitates meeting of needs of cows in various stages of growth and development and milk production of lactating cows, and has good economic and social benefits.

Owner:GUANGXI GUANGLIAN FEED

Preparation method of large-particle-size high-viscosity methyl silicon oil emulsion

ActiveCN106700095AImprove stabilityHigh viscosityCosmetic preparationsHair cosmeticsEmulsionSilicone oil

The invention discloses a preparation method of large-particle-size high-viscosity methyl silicon oil emulsion. The high-viscosity methyl silicon oil emulsion is prepared by adopting advanced efficient-shear emulsion equipment. The large-particle-size methyl silicon oil emulsion with the particle size D50 of more than 20mum is prepared by selecting high-viscosity methyl silicon oil as well as a surfactant and water that are added for adjustment. The large-particle-size high-viscosity methyl silicon oil emulsion prepared by the invention is simple and efficient in preparation process and easy in process operation, and has a prominent application effect in personal care products; especially, the large-particle-size high-viscosity methyl silicon oil emulsion can be compounded with small-particle-size silicon oil emulsion in hair care products, so that hair has excellent dry-wet combing performance and smooth and soft handfeel.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

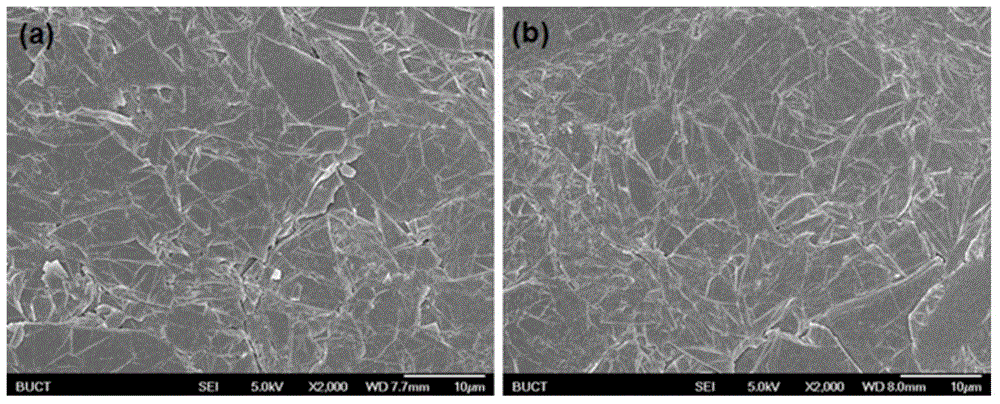

Polyimide nano-fiber membrane with crosslinked structure and preparation thereof

ActiveCN102766270BImprove mechanical propertiesThe degree of cross-linking can be controlledMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides a polyimide nano-fiber membrane with a crosslinked structure and preparation thereof, belonging to the technical field of polyimide nano-fiber membrane. Polyamide acid solution which is a prepolymer of polyimide is synthesized from diamine and a dibasic acid anhydride monomer. And polyimide nano-fiber membrane is prepared by the electrospinning technology. The polyimide nano-fiber membrane is then treated in alkali lye with PH of 8.5-10.5 for 10s-3h, washed and dried, which is then thermal-imidized through gradient heating up and cooled down to obtain polyimide nano-fiber membrane with the crosslinked structure. The polyimide nano-fiber membrane with the crosslinked structure prepared by the invention has the advantages of high strength, simple implementation process, easiness in processing and good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

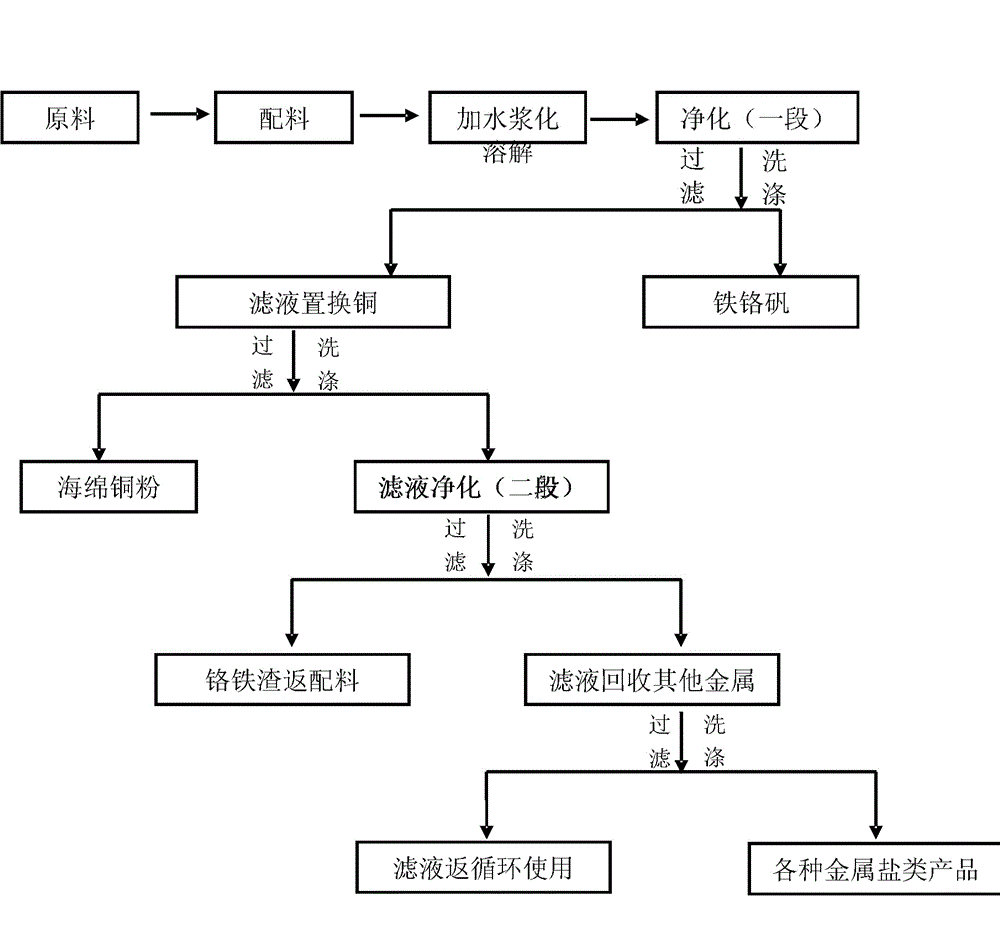

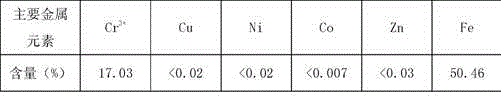

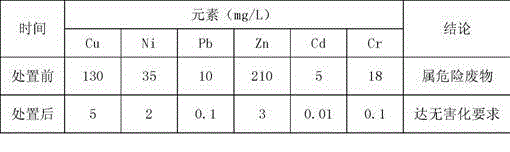

Harmless treatment method for multi-metal coexisting chromium-containing waste

ActiveCN103550903AGuaranteed detoxificationReduce manufacturing costChromium trioxideFerric oxidesHydrogenSlurry

The invention discloses a harmless treatment method for multi-metal coexisting chromium-containing waste. The harmless treatment method comprises the following steps: (1) preparing the multi-metal coexisting chromium-containing waste raw material; (2) pulping the prepared material to prepare mixed pulp, and then adding concentrated sulfuric acid into the mixed pulp; (3) adjusting the pH (potential of Hydrogen) to be 3.5-3.8 by using calcium carbonate to produce iron-chromium-alum precipitate, filtering, wherein the content of Fe in the filtrate is 0.05-0.1 g / L, and the content of the Cr in the filtrate is 0.1-0.5 g / L, and finally recovering other metals by using a conventional means; (4) washing the iron-chromium-alum precipitate under the condition of pH of 6-9 to obtain stable iron, chromium and alum, and detecting leaching toxicity to make sure that the leaching toxicity of total chromium is less than 5 mg / L, the leaching toxicity of Cu is less than 10 mg / L, the leaching toxicity of Zn is less than 10 mg / L, and the leaching toxicity of Ni is less than 5mg / L so as to reach the national harmless standard.

Owner:青川县天运金属开发有限公司

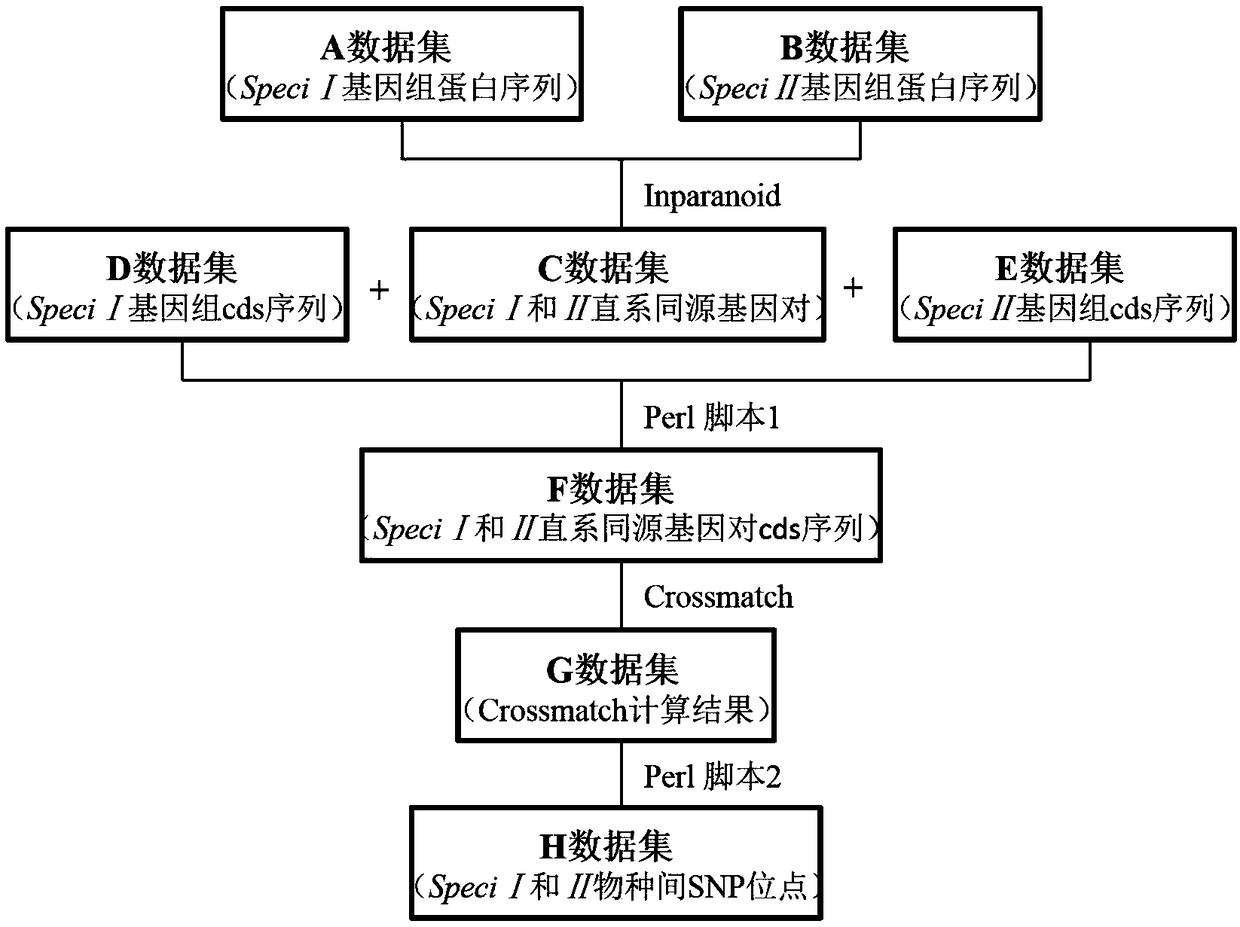

Method for batch computing genome coding region SNP sites among related species

ActiveCN109243531ABatch efficientComputationally comprehensive and accurateProteomicsGenomicsOrthologous GenePaired comparison

The invention discloses a method for batch computing genome coding region SNP sites among related species. According to the method for computing the genome coding region SNP sites (coding SNP, cSNP) among the related species, an InParanoid program for clustering searching orthologous genes is comprehensively utilized after the Blast-based paired comparison results based on the Crossmatch carrier shielding software for comparing two sets of DNA coding region sequences (cds sequences) through combination of the Perl scripting language programming method. The experiment proves that the method forbatch computing the cSNP sites among the related species is systematic and has the advantages of good repetition effect, high speed and easy implementation of batch, automation and process flow in case of detecting the cSNP among the related species.

Owner:JIANGSU ACAD OF AGRI SCI

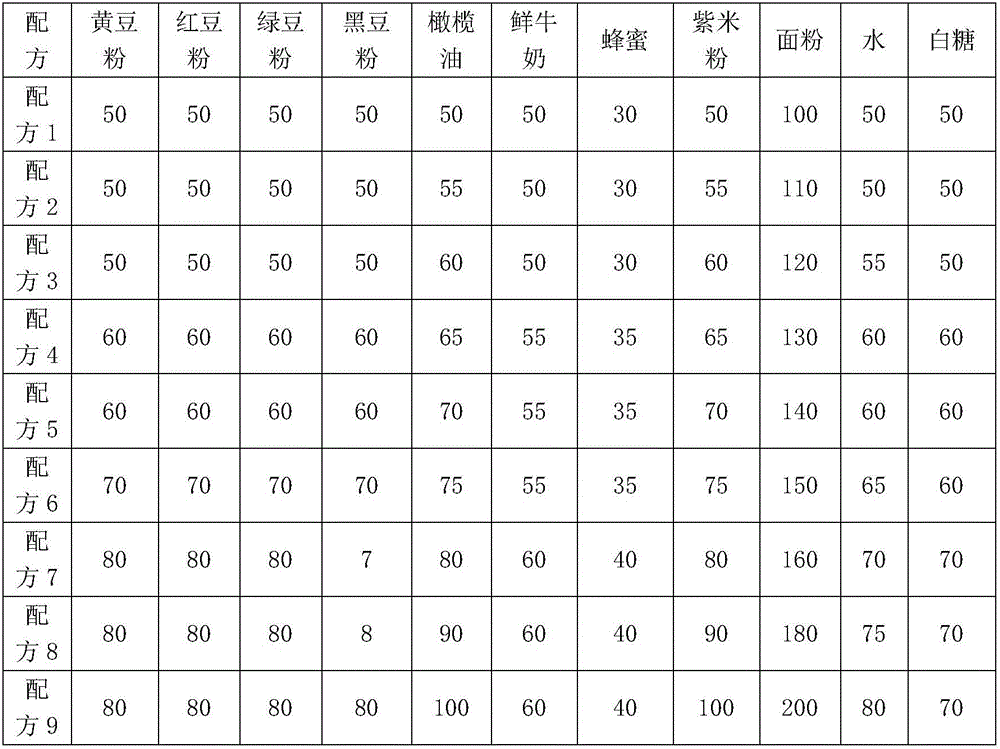

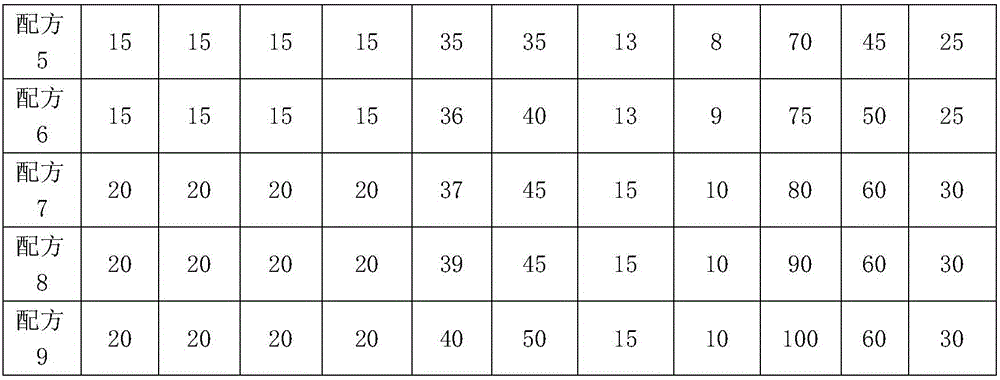

Low-fat biscuit for skin beautifying and production method thereof

InactiveCN106386983ASignificant progressPromote digestion and absorptionDough treatmentBakery productsBiotechnologyCow milk

The invention discloses a low-fat biscuit for skin beautifying and a production method thereof, The low-fat biscuit for skin beautifying is prepared from, by weight, 50-80 parts of soybean powder, 50-80 parts of red bean powder, 50-80 parts of black bean powder, 50-80 parts of mung bean powder, 50-100 parts of olive oil, 50-60 parts of fresh milk, 30-40 parts of honey, 50-100 parts of purple rice powder, 100-200 parts of flour, 50-80 parts of water and 50-70 parts of white sugar. The production method includes the following steps: mixing the soybean powder, the red bean powder, the black bean powder, the mung bean powder and the flour evenly; adding the fresh milk, the water, the white sugar and the like gradually; mixing and stirring; kneading the mixture into a dough; baking the dough to obtain the biscuit. The biscuit has the advantages of low fat and good palatability, and has obvious effects of tonifying qi and replenishing blood, tonifying spleen and warming stomach and beautifying skin.

Owner:韦尚仁

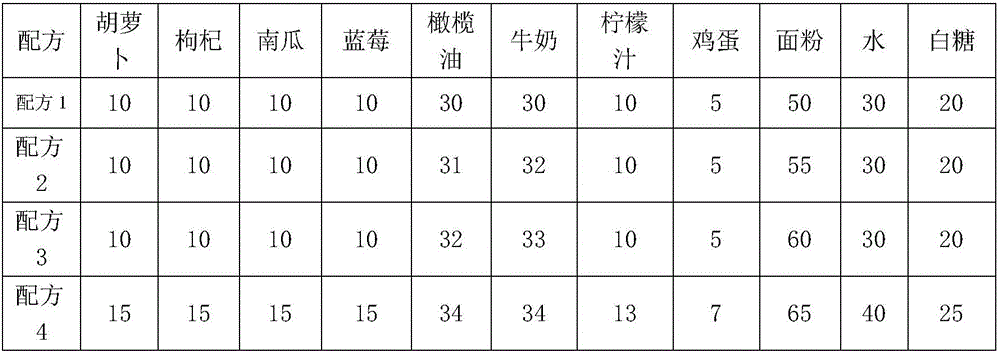

Cookies with function of enhancing eyesight and production method thereof

InactiveCN106417534AProcess safetyLow costDough treatmentBakery productsBiotechnologyCooking & baking

The invention discloses cookies with the function of enhancing eyesight and a production method thereof. The cookies are prepared from, by weight, 10-20 parts of carrots, 10-20 parts of fructus lycii, 10-20 parts of pumpkins, 10-20 parts of blueberries, 30-40 parts of olive oil, 30-50 parts of milk, 10-15 parts of lemon juice, 5-10 parts of eggs, 50-100 parts of flour, 30-60 parts of water and 20-30 parts of white sugar. The production method includes the following steps that the eggs, milk, water, white sugar and flour are mixed and stirred, the mixture is kneaded into dough, the carrots are added, and the cookies are produced through baking. The cookies have the advantages of being low in fat and good in palatability, and have the obvious function of enhancing eyesight.

Owner:吴福勤

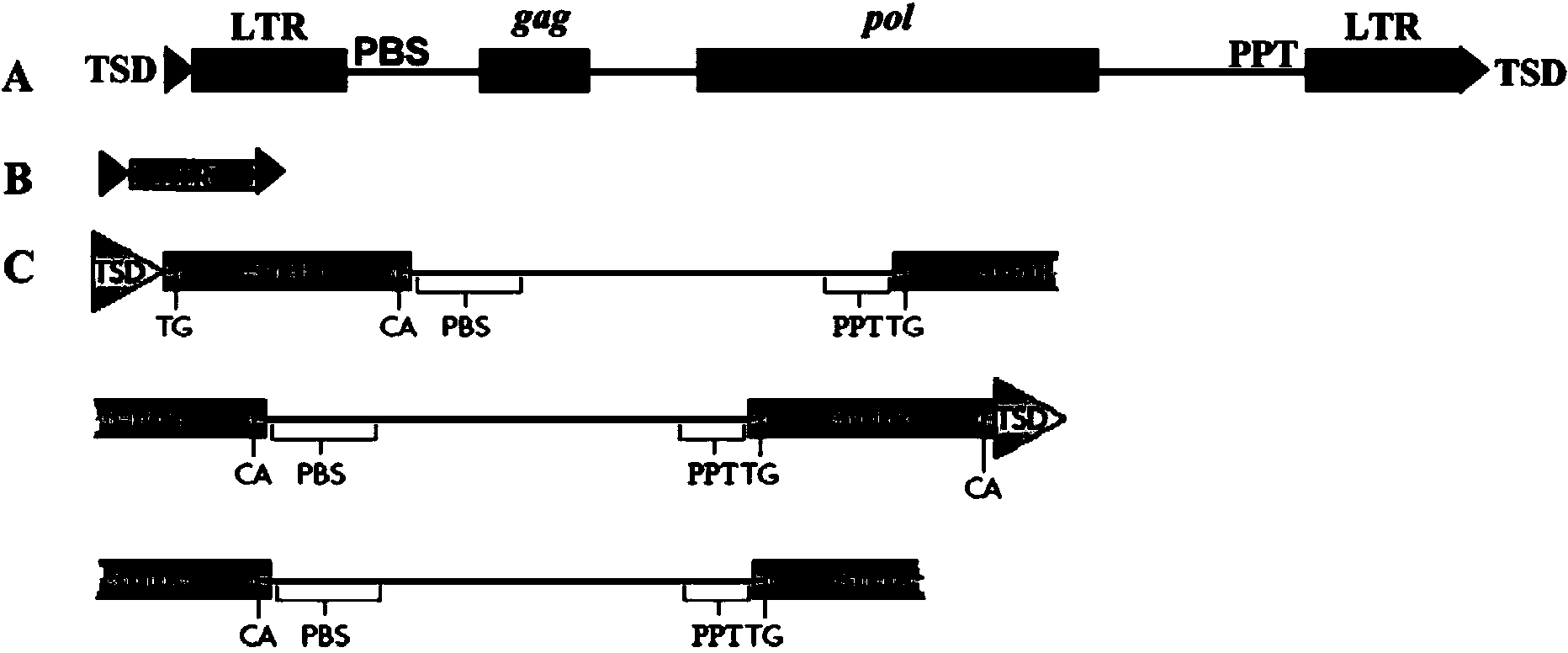

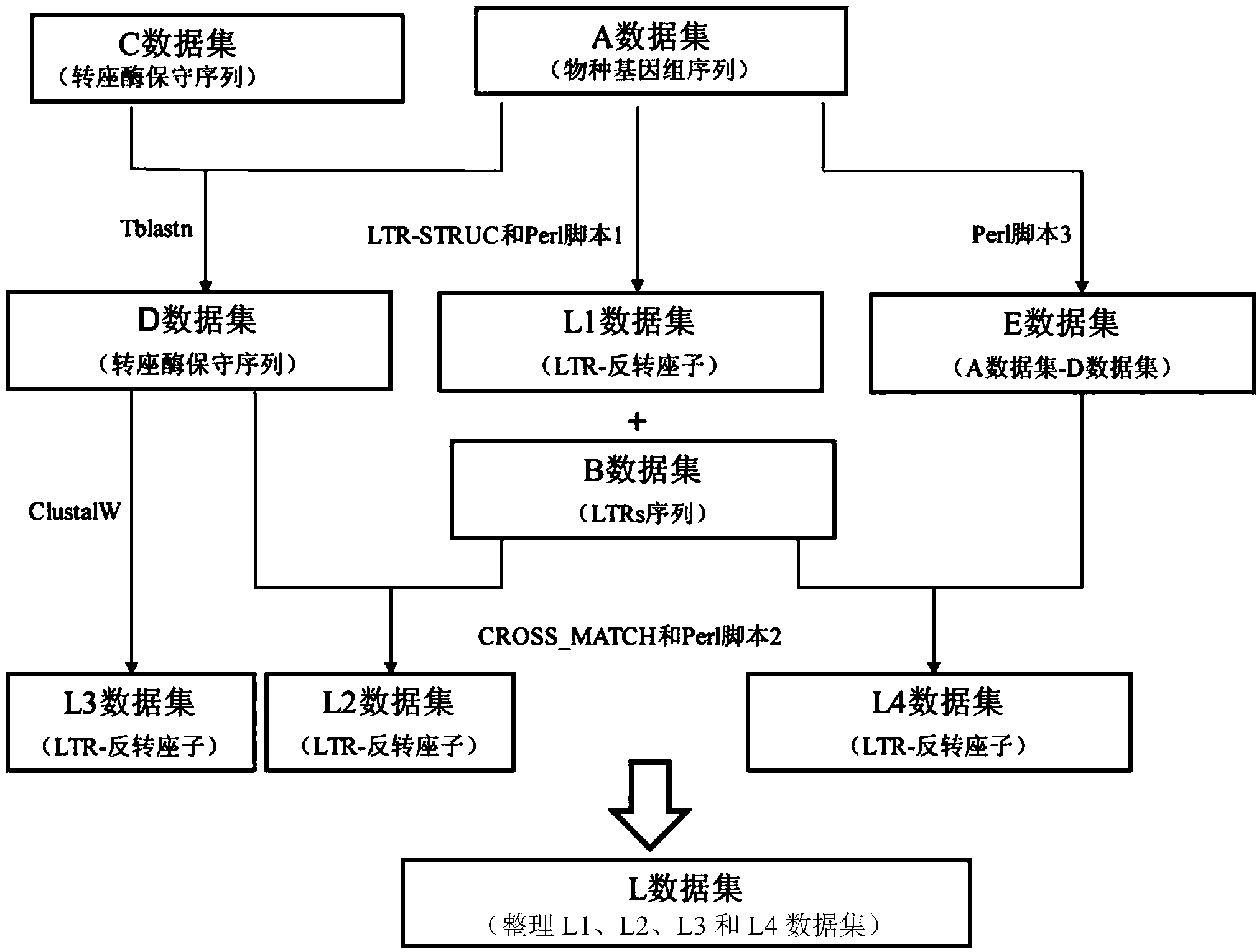

Method for batch inspection of plant genome LTR-retrotransposon

The invention discloses a method for batch inspection of plant genome LTR-retrotransposon. An LTR_STRUC program based on structural characteristics and searching from the beginning, a CROSS_MATCH program based on homology searching and a CLUSTALW comparison program based on sequence similarity are comprehensively applied in the method for the batch inspection of the plant genome LTR-retrotransposon, and Perl scripting language programming and other methods are combined. Experimental results show that the method for the batch inspection of the plant genome LTR-retrotransposon is relatively systematic, the effect for detecting the direct repeat of the inserting sites of the plant genome LTR-retrotransposon is good, speed is high, and process operation is easy to achieve. According to the method, the frequently-used software for detecting the plant genome LTR-retrotransposon and the Perl scripting language programming are combined, and certain defects of the frequently-used software are made up. The method can play an important role in genome annotation and the batch inspection of the plant genome LTR-retrotransposon.

Owner:JIANGSU ACAD OF AGRI SCI

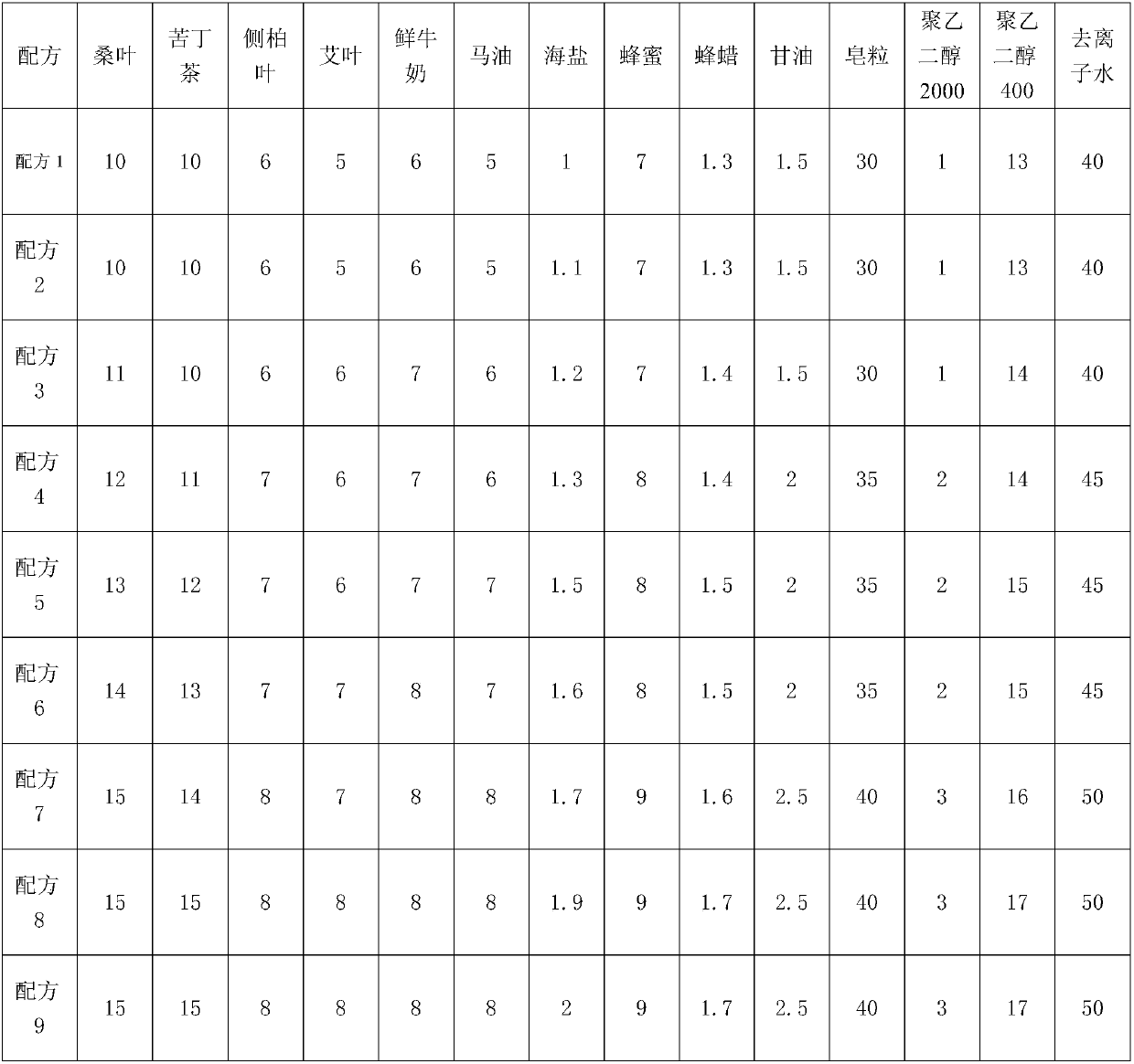

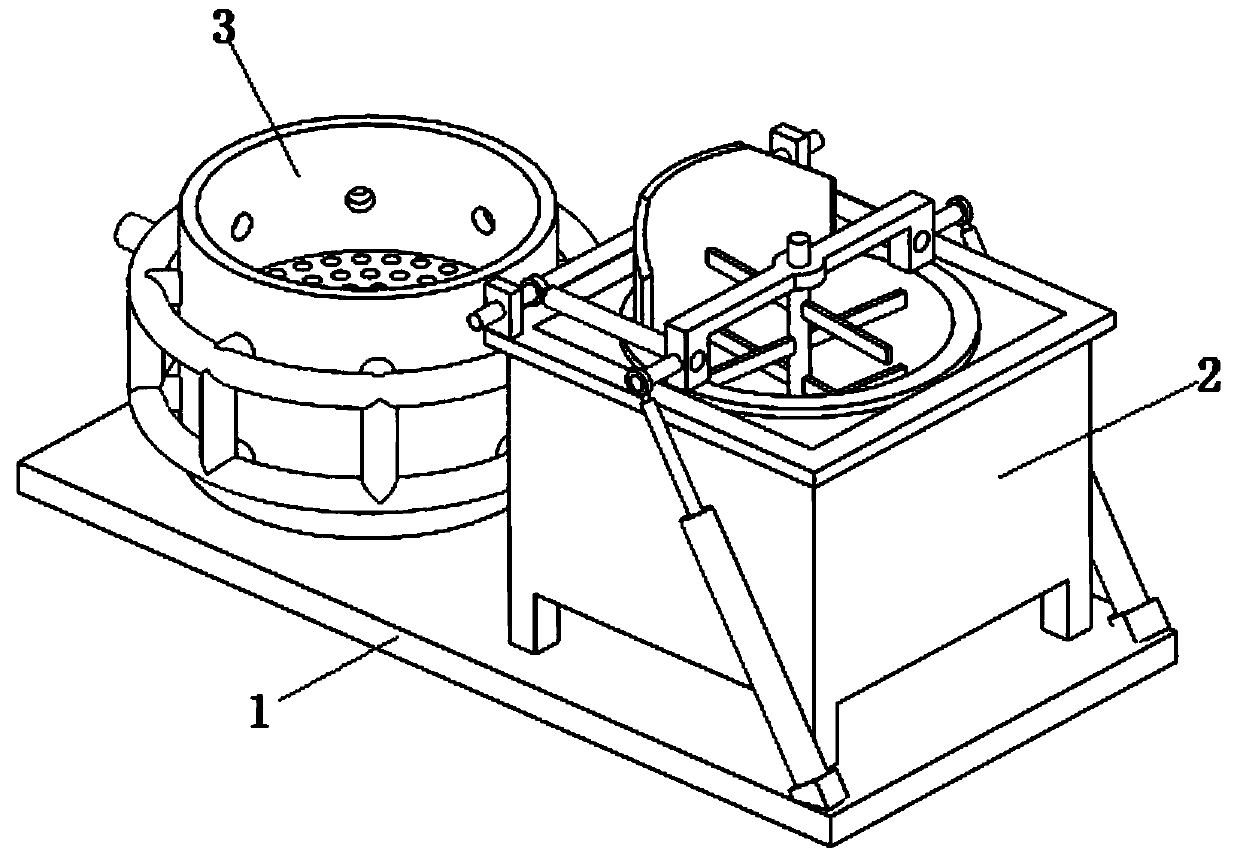

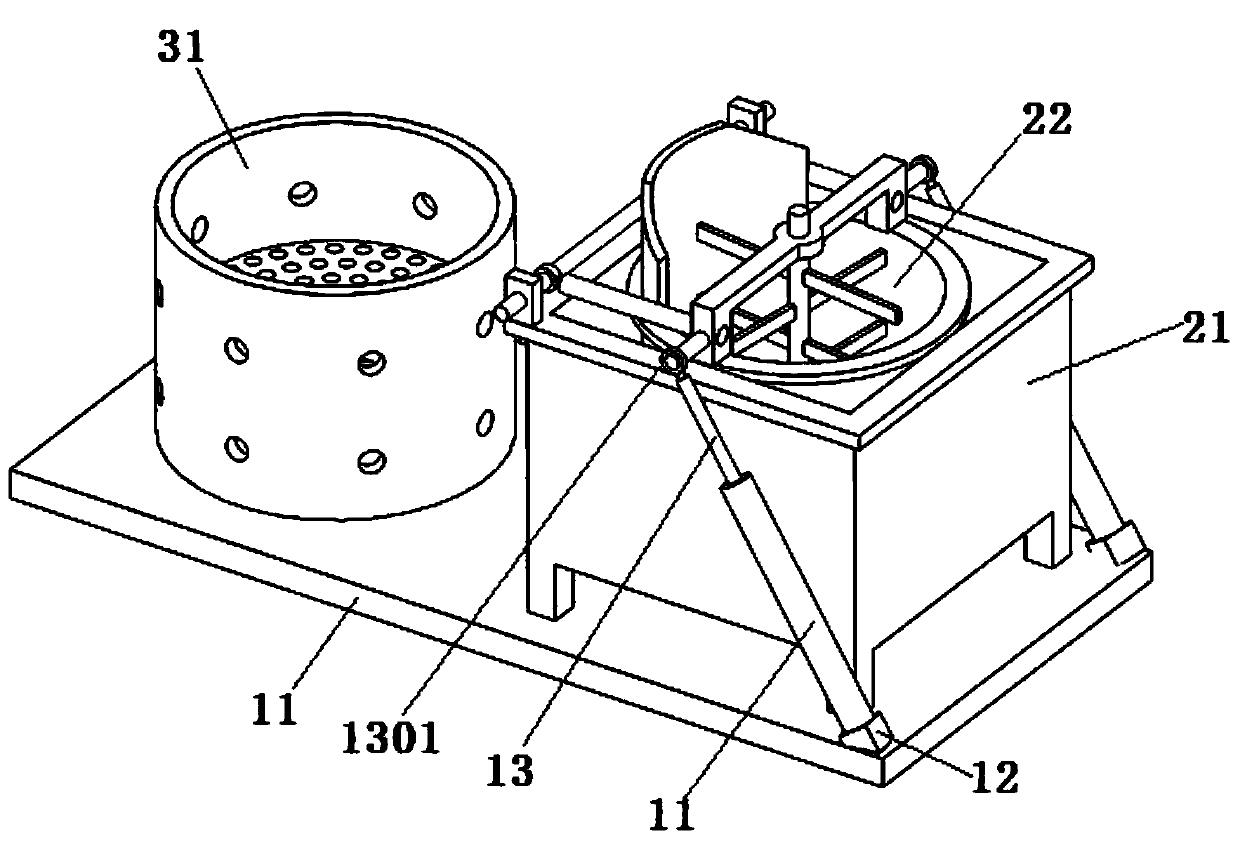

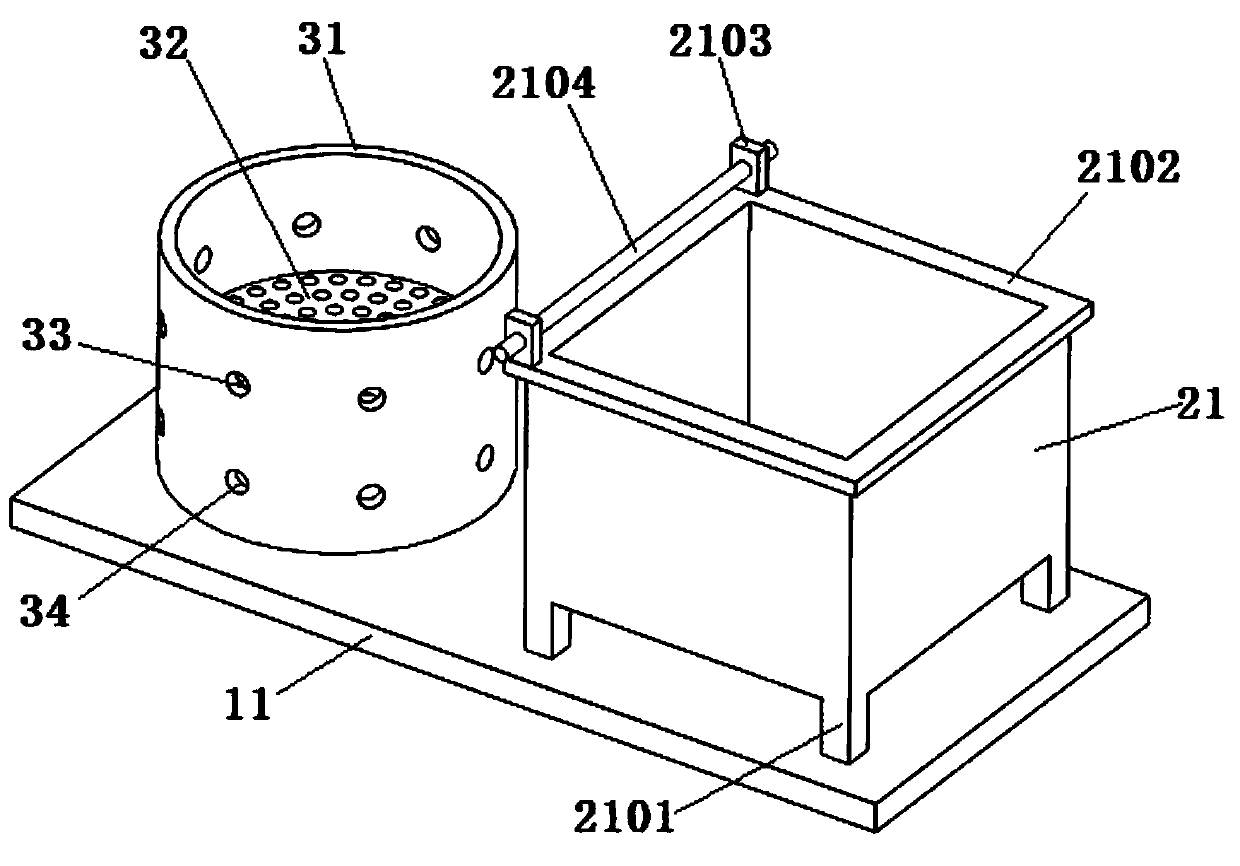

Shampoo soap and production method thereof

InactiveCN109810810ASignificant progressSuitable for useSoap detergents with organic compounding agentsHair cosmeticsBiotechnologyPEG 400

The invention discloses a shampoo soap and a production method thereof. The shampoo soap is prepared from the following raw materials in parts by weight: 10-15 parts of mulberry leaves, 10-15 parts ofbroadleaf holly leaf, 6-8 parts of arborvitae leaves, 5-8 parts of folium artemisiae argyi, 6-8 parts of fresh milk, 5-8 parts of horse oil, 1.0-2.0 parts of sea salt, 7-9 parts of honey, 1.3-1.7 parts of beeswax, 1.5-2.5 parts of glycerin, 45-60 parts of soap particles, 1-3 parts of polyethylene glycol 2000, 13-17 parts of polyethylene glycol 400, and 40-50 parts of deionized water. The production method comprises the following steps: heating the mulberry leaves, the folium artemisiae argyi, the broadleaf holly leaves, the arborvitae leaves and the deionized water, filtering, mixing with thefresh milk and the like, stirring, heating to melt polyethylene glycol 2000 and polyethylene glycol 400, adding the honey, propolis, and the like, stirring evenly, pouring into a mold, and cooling for molding. The soap has the characteristics of long-lasting fragrance, high applicability, capabilities of obviously whitening, resisting wrinkle and moisturizing skin, and can be used for bathing andshampooing.

Owner:莫程

Production method of fried puffed flavored fish skin

InactiveCN110810753AReduce generationReduce the impact of damageDomestic cooling apparatusLighting and heating apparatusCold airProcess engineering

The invention discloses a production method of fried puffed flavored fish skin. The production method comprises the following steps: S1, treating raw materials; S2, performing segmentation; S3, performing pickling; putting the cut fish skin into a pickling barrel, and pickling for 20-40 minutes; S4, frying for the first time; adjusting the oil temperature of the frying and cooling integrated equipment to 125-130 DEG C, performing low-temperature frying, and performing frying for 8 min; S5, performing cooling; turning on a cold air device for cooling to the normal temperature of 20-25 DEG C; S6, performing deep-frying puffing for the second time; adjusting the oil temperature of the frying and cooling integrated equipment to 170 DEG C, and carrying out secondary frying puffing by utilizingmoisture contained in the primary frying; S7, filtering oil; S8, performing cooling; S9, performing seasoning; S10, performing drying; and S11, performing modified atmosphere packaging. The fresh fishskin or frozen fish skin is adopted as a raw material, the flavor fish skin product is prepared through the procedures of cleaning, cutting, pickling and the like, a secondary frying method and a fusion puffing technology are employed, and the obtained flavor fish skin has special taste and high quality and is long in shelf life and easy to store.

Owner:安徽灵猫食品有限公司

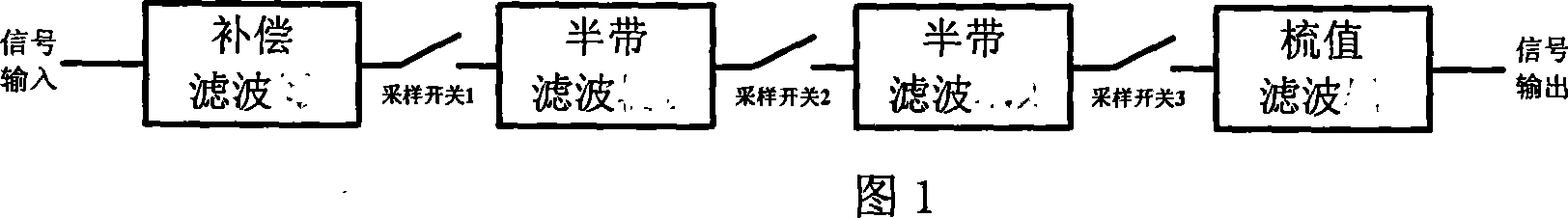

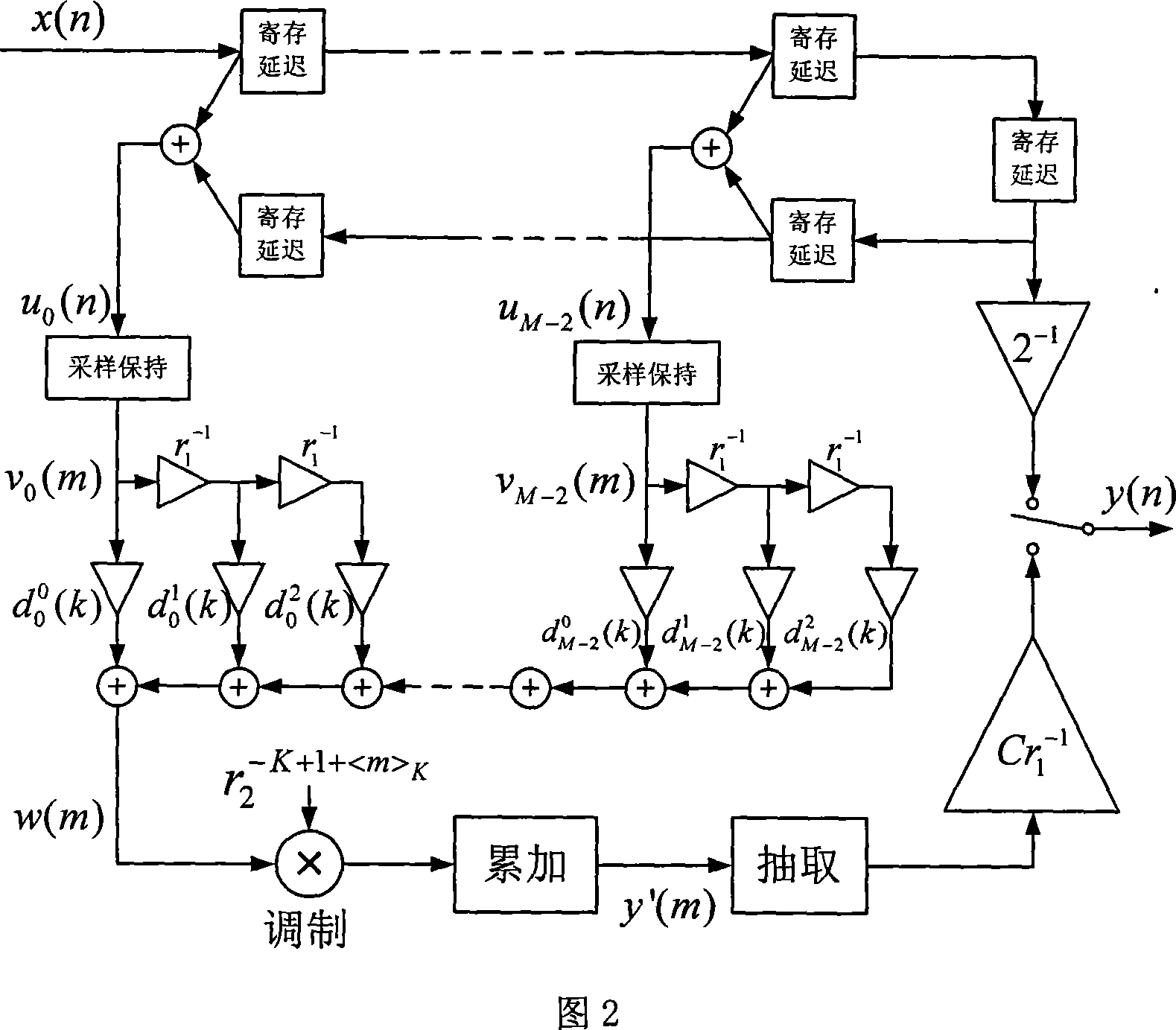

Semi-band filtering method for interpolation filtering in analog-digital conversion

InactiveCN101043217AImprove conversion accuracyReduce complexityDigital-analogue convertorsModularityFilter system

The invention relates to a half band filter method which is used in interpolating filter of digital to analog, it belongs to technology field of signal process. This half band filter method adopts mode of coefficient commix base decomposing, and combines concept of multi phase filter, by delaying consignation, adding from beginning to end, sampling and maintaining, weighting and adding, modulating and accelerating, taking out and zooming plus to half band filter. The advantages of the invention are following: the half band filter adopts method of coefficient commix base decomposing, and combines concept of multi phase filter, long shift operation can not be generated, data converting precision can be improved greatly, and complexity degree of program can not be added; using the half band filter of the invention, the design of flow and modularization are easy, and the hardware, territory distribution are more normal, it provides base of research and practice for automatization design and synthesis of filter system.

Owner:TSINGHUA UNIV

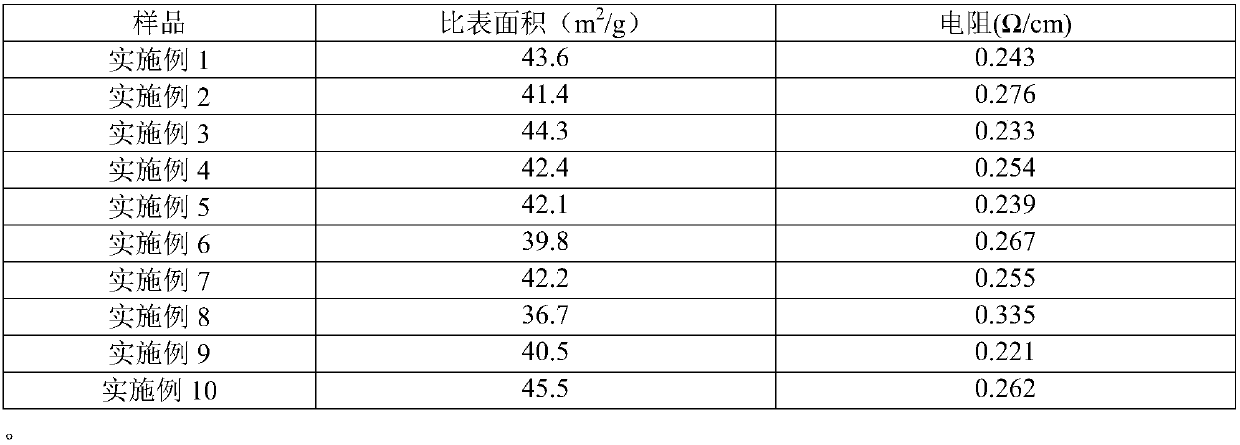

Light-duty high-temperature-resistant and high-specific-surface-area polyimide conductive pulp and preparation method therefor

ActiveCN107871541AHigh temperature resistance hasChemically stableNon-conductive material with dispersed conductive materialCable/conductor manufactureImidePolymer science

The invention discloses light-duty high-temperature-resistant and high-specific-surface-area polyimide conductive pulp and a preparation method therefor, and belongs to the technical field of conductive materials. Polyimide pulp is taken as a skeleton carrier, and a surface layer of the polyimide pulp is a high-conductivity or high-thermal-conductivity metal layer. The method comprises the steps:firstly scattering the polyimide pulp in deionized water in a uniform manner; secondly adding ammonia water to the deionized water, placing the polyimide pulp in a metal saline solution after settlingout, and enabling the polyimide pulp to carry metal ions; thirdly carrying out the reduction of the metal ions in a reducing solution; finally carrying out the high-temperature thermal processing ofpolyamide acid pulp carried by metal, thereby obtaining the polyimide conductive pulp with the surface being coated with the metal layer. Through combining the advantages of the polyimide and the metal layer, the polyimide conductive pulp is resistant to high temperature, is high in conductivity, is low in density, is high in specific surface area, and is a novel high-performance organic / inorganiccomposite conductive material.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing polyimide/silver composite electrical conductivity fibers

ActiveCN101775670BHigh temperature resistantChemically resistantFibre typesMonocomponent synthetic polymer artificial filamentFiberSurface layer

The invention relates to a method for preparing polyimide / silver composite electrical conductivity fibers, which comprises the following steps: firstly preparing polyamic acid fibers from polyamic acid solution; then drawing polyamic acid fibers at constant speed to carry out iron exchange in soluble silver salt solution to make silver irons diffuse and immerse the surface of the polyamic acid fibers and combined with amic acid radical to obtain a silver salt compound of polyamic acid; and finally by heating, making the silver irons reduced and accumulate on the surface and making polyamic acid fibers cyclized into polyimide fibers to obtain the conductive polyimide / silver composite electrical conductivity fibers. The method of the invention has the advantages of integrated molding, simple process, low cost, no toxicity and no pollution, capacity of being used for large-scale industrial production, high adhesive strength of the silver salt on the surface layer of the fibers, metallic luster, excellent electrical conductivity and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com