Cow feed and production method thereof

A feed and cow technology, applied in animal feed, animal feed, applications, etc., can solve the problems of increased cow breeding costs, high cost, and insufficient applicability, and achieve the effects of preventing loss of appetite, increasing production, and extensive planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

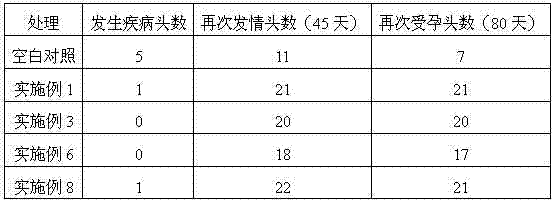

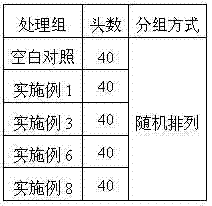

Examples

Embodiment 1

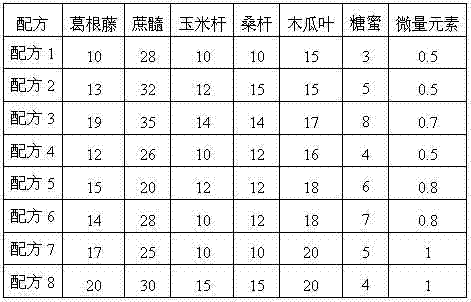

[0030] Embodiment 1 cow feed processing formula

[0031] Can adopt following formula to carry out the processing of cow feed of the present invention:

[0032]

[0033] The above formulas are all implemented in parts by weight.

Embodiment 2

[0034] Embodiment 2 cow feed production method (1)

[0035] (1) Pre-grind the trace elements first, pass through a 80-mesh sieve, then mix the molasses and trace elements according to the formula ratio at 25°C for 20 minutes, mix thoroughly, dehydrate, dry, crush, pass through a 60-mesh sieve, and set aside. The ingredients of the trace element formula are: copper sulfate, zinc sulfate, manganese sulfate, ferrous sulfate, calcium iodate, magnesium sulfate, and sodium selenite, and the molar ratio of each trace element in the cow feed is: 1:1: 1:1:2:5:0.1.

[0036] (2) Collect or purchase Pueraria vines free from pests and diseases, dry and crush them through a 60-mesh sieve for later use.

[0037] (3) Weigh sugarcane pith, papaya leaves, corn stalks and mulberry stalks according to the proportion of the formula, crush them to 60 mesh, mix them evenly, add 3% lactobacillus in the weight of the mixture, control the water content of the weight of the materials to 55%, stir the...

Embodiment 3

[0039] Embodiment 3 cow feed production method (2)

[0040] (1) Pre-grind trace elements first, pass through 80-mesh sieve, then mix molasses and trace elements according to the formula ratio at 35°C for 40 minutes, mix thoroughly, dehydrate, dry, crush, pass through 80-mesh sieve, and set aside. The composition of the trace element formula is: copper sulfate, zinc sulfate, manganese sulfate, ferrous sulfate, calcium iodate, magnesium sulfate, and sodium selenite. The molar ratio of each trace element in the cow feed is: 1.5:1.5: 1.5:1.5:3:8:0.2.

[0041] (2) Collect or purchase pueraria vines free from pests and diseases, dry and crush them through an 80-mesh sieve for later use.

[0042] (3) Weigh sugarcane pith, papaya leaves, corn stalks and mulberry stalks according to the proportion of the formula, crush them to 80 mesh, mix them evenly, add lactobacillus with 5% of the weight of the mixture, control the water content of the weight of the materials to 65%, stir them e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com