Spirulina organic fodder for dairy cow

A technology of organic feed and spirulina, applied in animal feed, animal feed, application and other directions, can solve problems such as environmental pollution, and achieve the effects of good palatability, convenient transportation and easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

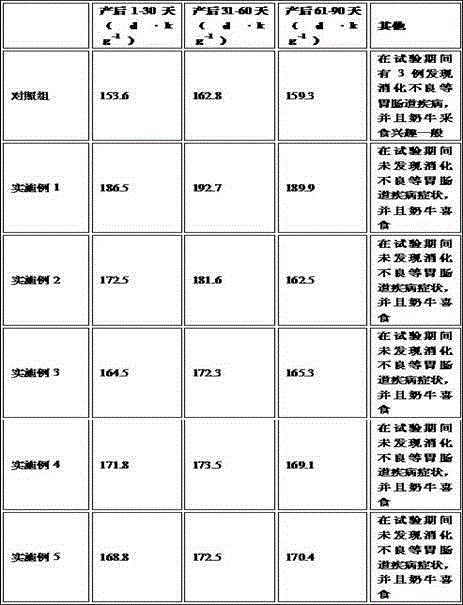

Examples

Embodiment 1

[0022] A spirulina organic feed for dairy cows, the preparation method of which is as follows:

[0023] Ingredients Handling:

[0024] Mix the fermented substrates according to the proportions: according to the parts by weight, 30 parts of rice husks, 180 parts of spirulina powder, 20 parts of corn stalk powder, 5 parts of medical stone powder, 1 part of astragalus powder are respectively pulverized and mixed with a pulverizer. Polyphenol oxidase, xylanase, and microbial starter are mixed with appropriate amount of water, added to the mixer and stirred, and the moisture content is controlled at about 75%;

[0025] Fermentation:

[0026] The fermentation piles are stacked, the fermentation temperature is 33 ° C, and the fermentation is carried out for 10 days, during which it is turned 3 times;

[0027] Sieving and Granulation:

[0028] The low-temperature drying method is used to dry the processed materials, and then the powdered organic feed is prepared for inspection, pac...

Embodiment 2

[0032] A spirulina organic feed for dairy cows, the preparation method of which is as follows:

[0033] Ingredients Handling:

[0034] Mix the fermented substrates according to the proportions: according to the parts by weight, 52 parts of rice husks, 120 parts of spirulina powder, 30 parts of corn stalk powder, 2 parts of medical stone powder, 2 parts of astragalus powder are respectively pulverized and mixed with a pulverizer. Polyphenol oxidase, xylanase, and microbial starter are mixed with appropriate amount of water, added to the mixer and stirred, and the moisture content is controlled at about 60%;

[0035] Fermentation:

[0036] The fermentation piles are stacked, the fermentation temperature is 35 ° C, and the fermentation is carried out for 8 days, during which time it is turned 4 times;

[0037] Sieving and Granulation:

[0038] The low-temperature drying method is used to dry the processed materials, and then the powdered organic feed is prepared for inspection...

Embodiment 3

[0042] A spirulina organic feed for dairy cows, the preparation method of which is as follows:

[0043] Ingredients Handling:

[0044] The fermentation substrates are mixed according to the proportions: 40 parts of rice husks, 150 parts of spirulina powder, 25 parts of corn stalk powder, 4 parts of medical stone powder, and 1 part of astragalus powder are pulverized with a pulverizer and mixed, respectively, in parts by weight. Polyphenol oxidase, xylanase, and microbial starter are mixed with appropriate amount of water, added to the mixer and stirred, and the moisture content is controlled at about 68%;

[0045] Fermentation:

[0046] The fermentation piles are stacked, the fermentation temperature is 34 ° C, and the fermentation is carried out for 9 days, during which it is turned 3 times;

[0047] Sieving and Granulation:

[0048] The low-temperature drying method is used to dry the processed materials, and then the powdered organic feed is prepared for inspection, pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com