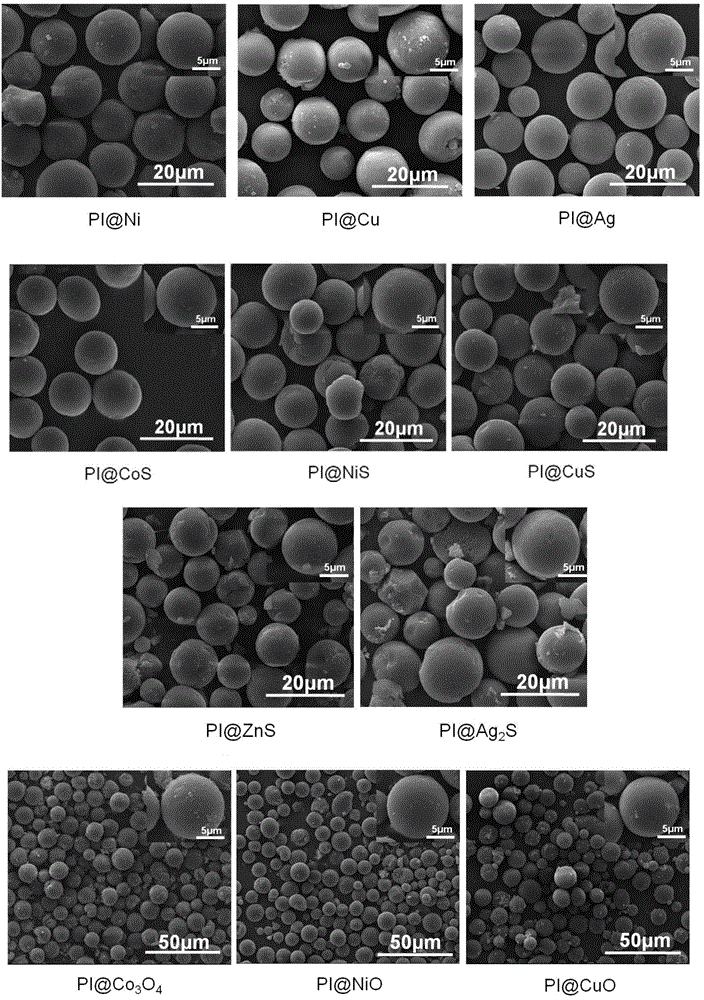

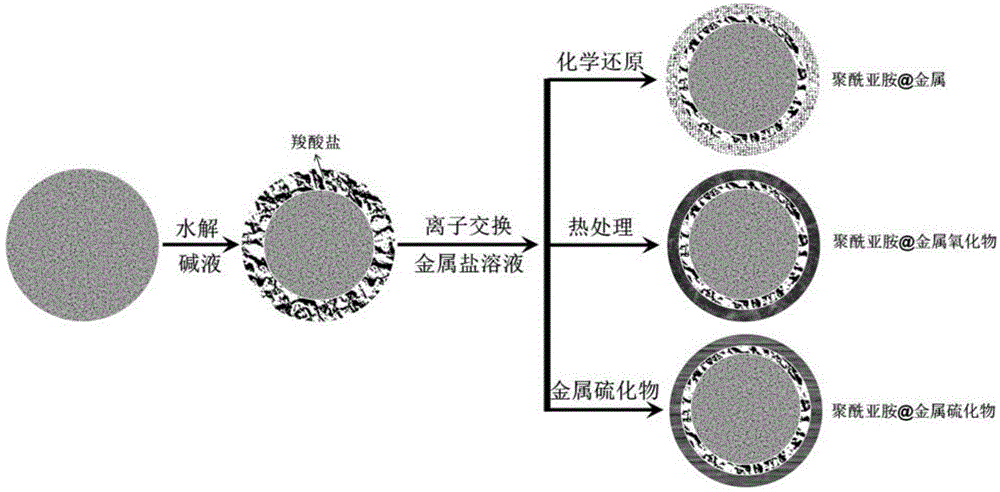

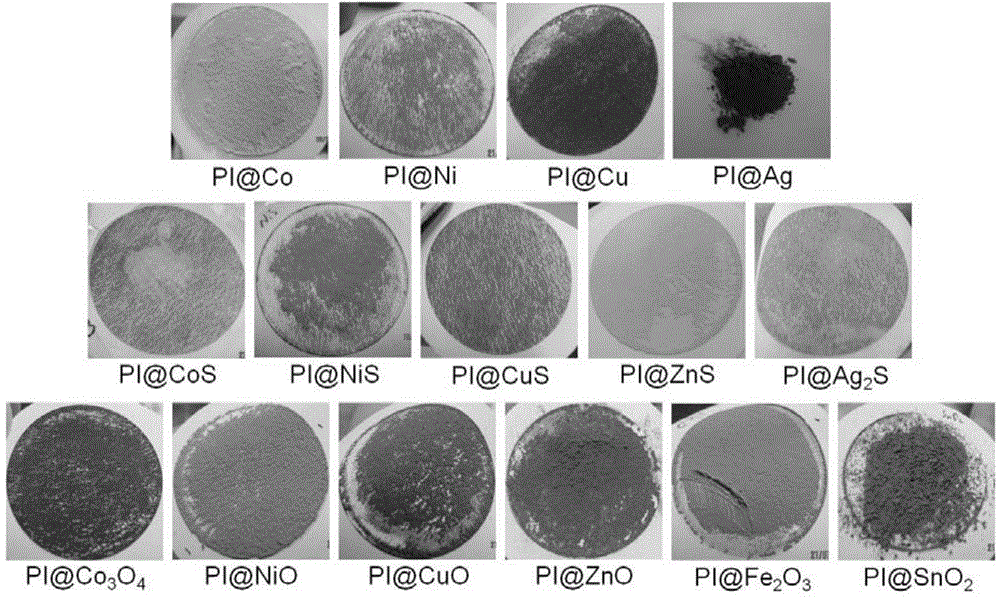

Preparation method for core-shell type polyimide@metal/metal oxide/metal sulfide composite microballoons

A technology of metal sulfide and polyimide, which is applied in the field of preparation of core-shell polyimide metal/metal oxide/metal sulfide composite microspheres, and can solve problems such as no core-shell structure composite microspheres , to achieve the effect of good industrialization prospect, good thermal stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A: Add polyimide microspheres to 4M KOH solution at 40°C, ultrasonically disperse for 5 minutes, and hydrolyze the solution for 30 minutes under stirring conditions, and the imide bonds on the surface of the polyimide are broken to form amide groups and potassium carboxylate. Filter through a membrane filter and rinse with plenty of deionized water.

[0032] B: Under stirring conditions, the microspheres were immersed in 0.1M silver nitrate aqueous solution for 30 minutes, and the potassium ions and silver ions on the surface of the microspheres had an ion exchange reaction. Filter through a membrane filter and rinse with plenty of deionized water.

[0033] C: Add the microspheres into 0.01M dimethylamine borane (DMAB) solution, stir for 10 minutes, and undergo a chemical reduction reaction with silver ions. The silver ions are reduced to metallic silver, and the core is polyimide, and the shell is obtained. Polyimide-silver (PIAg) composite microspheres of metallic s...

Embodiment 2

[0035] A: Add polyimide microspheres to 4M NaOH solution at 50°C, ultrasonically disperse for 5 minutes, and hydrolyze the solution for 20 minutes under stirring. The imide bond on the surface of polyimide is broken to form amide groups and carboxyl Sodium acid. Centrifuge, wash with deionized water, and repeat the operation 3-4 times.

[0036] B: Under stirring conditions, the microspheres were immersed in 0.1M copper nitrate aqueous solution for 30 minutes, and the potassium ions and copper ions on the surface of the microspheres had an ion exchange reaction. Centrifuge, wash with deionized water, and repeat the operation 3-4 times.

[0037] C: Add the microspheres into 0.02M dimethylamine borane solution, stir at 50°C for 20 minutes, and undergo a chemical reduction reaction with copper ions. The copper ions are reduced to metallic copper, and the core can be obtained as polyimide. The shell is the polyimide copper (PICu) composite microsphere of metal copper. The micros...

Embodiment 3

[0040] A: Add polyimide microspheres to 4M KOH solution at 30°C, ultrasonically disperse for 5 minutes, and hydrolyze the solution for 60 minutes under stirring. The imide bond on the surface of polyimide is broken to form amide groups and carboxyl Potassium acid. Filter through a membrane filter and rinse with plenty of deionized water.

[0041] B: Under stirring conditions, the microspheres were immersed in 0.2M copper nitrate aqueous solution for 20 minutes, and the potassium ions and copper ions on the surface of the microspheres had an ion exchange reaction. Filter through a membrane filter and rinse with plenty of deionized water.

[0042] C: The temperature of the microspheres is raised to 400°C through programmed temperature control, and the temperature is kept for 3 hours. During the heat treatment, the copper ions react with the oxygen in the air to form copper oxide, and the core is polyimide, and the shell is copper oxide. Polyimide copper oxide (PICuO) composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com