Polyimide-based carbon fiber and preparation method thereof

A polyimide-based carbon fiber and polyimide fiber technology are applied in the field of carbon fibers to achieve the effects of reducing adverse effects, improving aromatization efficiency, and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

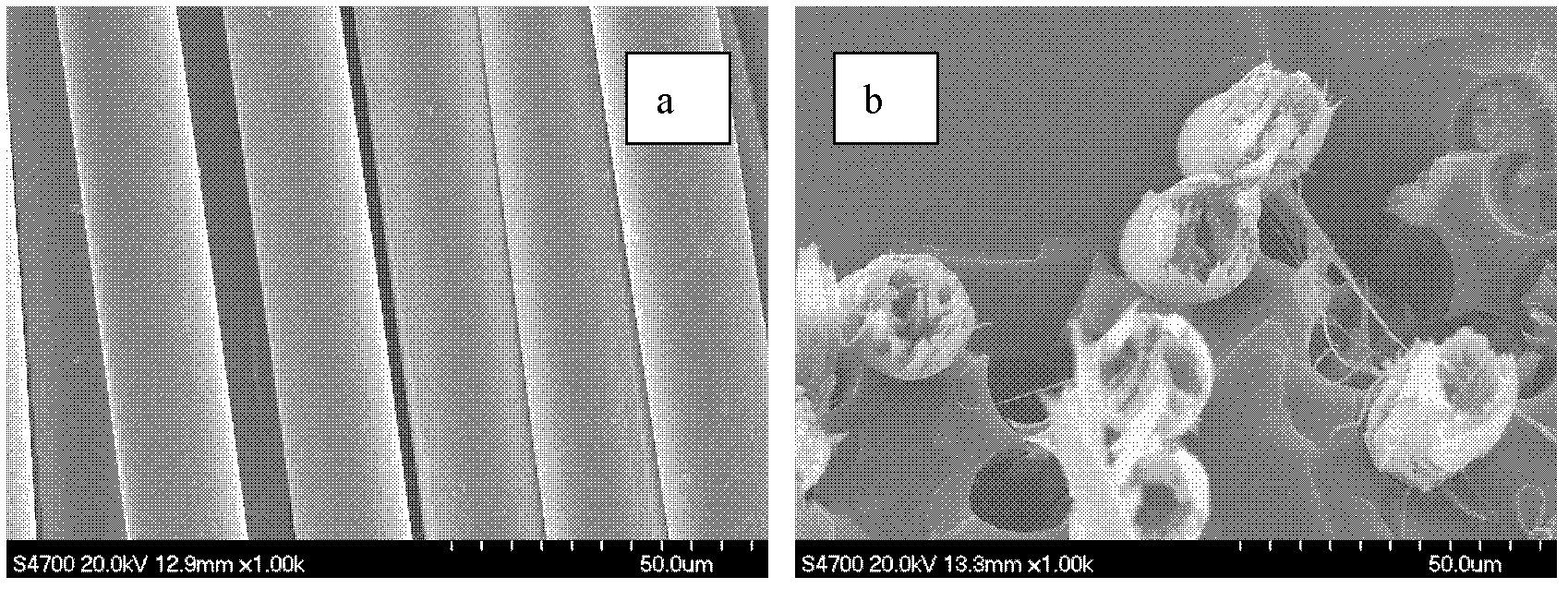

[0034] A: The polyamic acid solution obtained by PMDA / ODA polycondensation is used to prepare polyamic acid fiber by wet spinning process, and then the gradient thermal amidation process is used to imidize to prepare polyimide fiber;

[0035] B: Fix the polyimide fiber obtained in step A in a vacuum tube furnace, and apply a certain force along its axial direction, so that the fiber is always in a tensioned state during the heat treatment process;

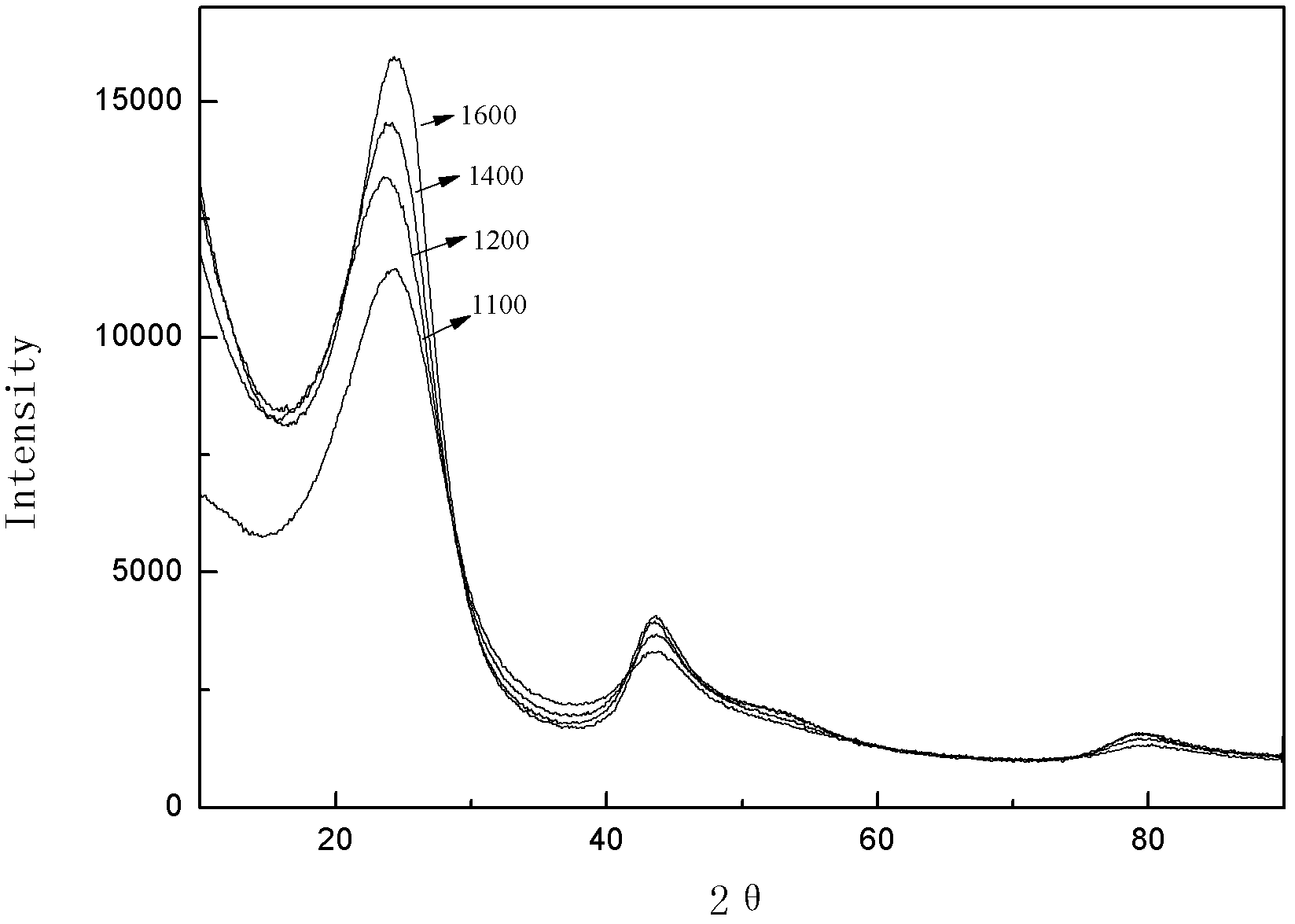

[0036] C: The polyimide fiber fixed in the tube furnace was heated in N 2 Gradient temperature rise under protection, set the temperature rise program, heat from room temperature to 1100°C at a rate of 10°C / min and keep at this temperature for 60min, N 2 The flow rate of the method is 100ml / min, and after the end, it is naturally cooled to obtain polyimide-based carbon fibers.

Embodiment 2

[0038] A: The polyamic acid solution obtained by PMDA / ODA polycondensation is used to prepare polyamic acid fiber by wet spinning process, and then the gradient thermal amidation process is used to imidize to prepare polyimide fiber;

[0039] B: Fix the polyimide fiber obtained in step A in a vacuum tube furnace, and apply a certain force along its axial direction, so that the fiber is always in a tensioned state during the heat treatment process;

[0040] C: The polyimide fiber fixed in the tube furnace was heated in N 2 Gradient temperature rise under protection, set the temperature rise program, heat from room temperature to 1200°C at a rate of 10°C / min and keep at this temperature for 60min, N 2 The flow rate of the method is 100ml / min, and after the end, it is naturally cooled to obtain polyimide-based carbon fibers.

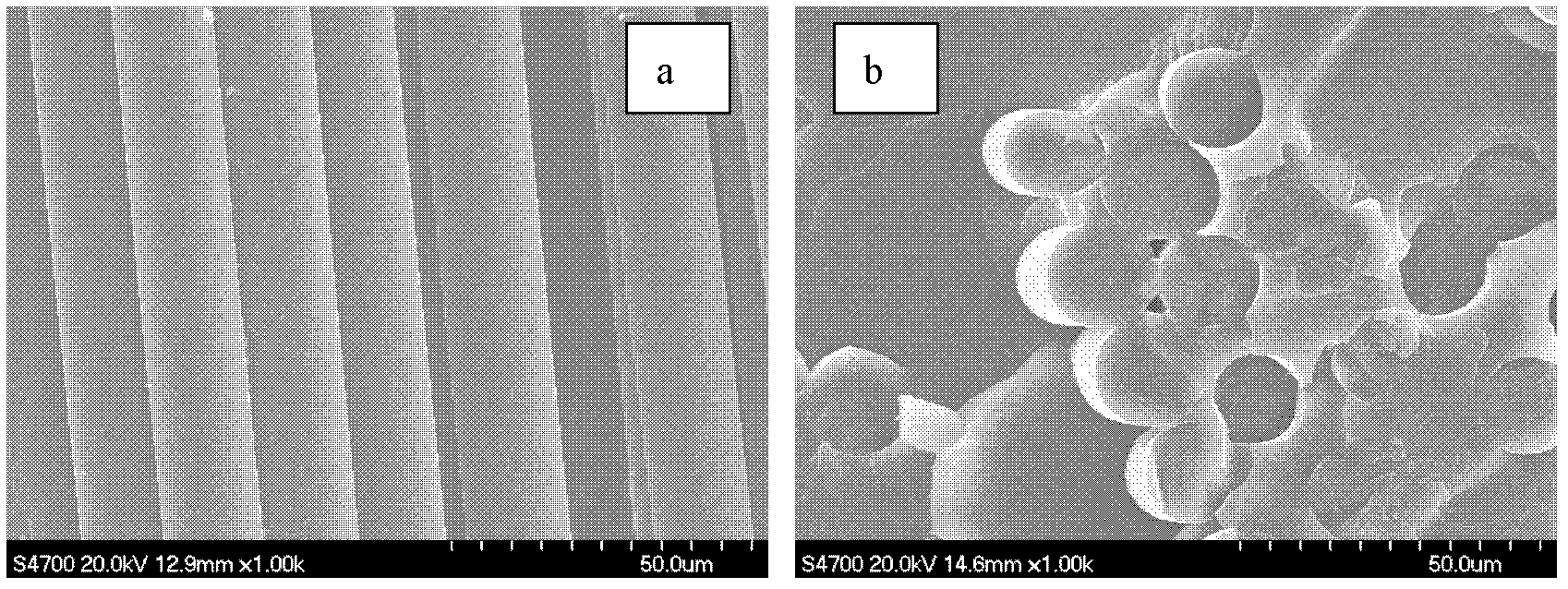

Embodiment 3

[0042] A: The polyamic acid solution obtained by PMDA / ODA polycondensation is used to prepare polyamic acid fiber by wet spinning process, and then the gradient thermal amidation process is used to imidize to prepare polyimide fiber;

[0043] B: Fix the polyimide fiber obtained in step A in a vacuum tube furnace, and apply a certain force along its axial direction, so that the fiber is always in a tensioned state during the heat treatment process;

[0044] C: The polyimide fiber fixed in the tube furnace was heated in N 2 Gradient temperature rise under protection, set the temperature rise program, heat from room temperature to 1400°C at a rate of 10°C / min and keep at this temperature for 60min, N 2 The flow rate of the method is 100ml / min, and after the end, it is naturally cooled to obtain polyimide-based carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com