Full-sealing energy-saving chamber indoor/outdoor vertical-hinged door

An indoor and outdoor fully sealed technology, applied in the direction of sealing device, parallel glass structure, wing fan arrangement, etc., can solve the problems of large heat dissipation, reduced cross-sectional area of profiles, poor sealing performance of side-hung doors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

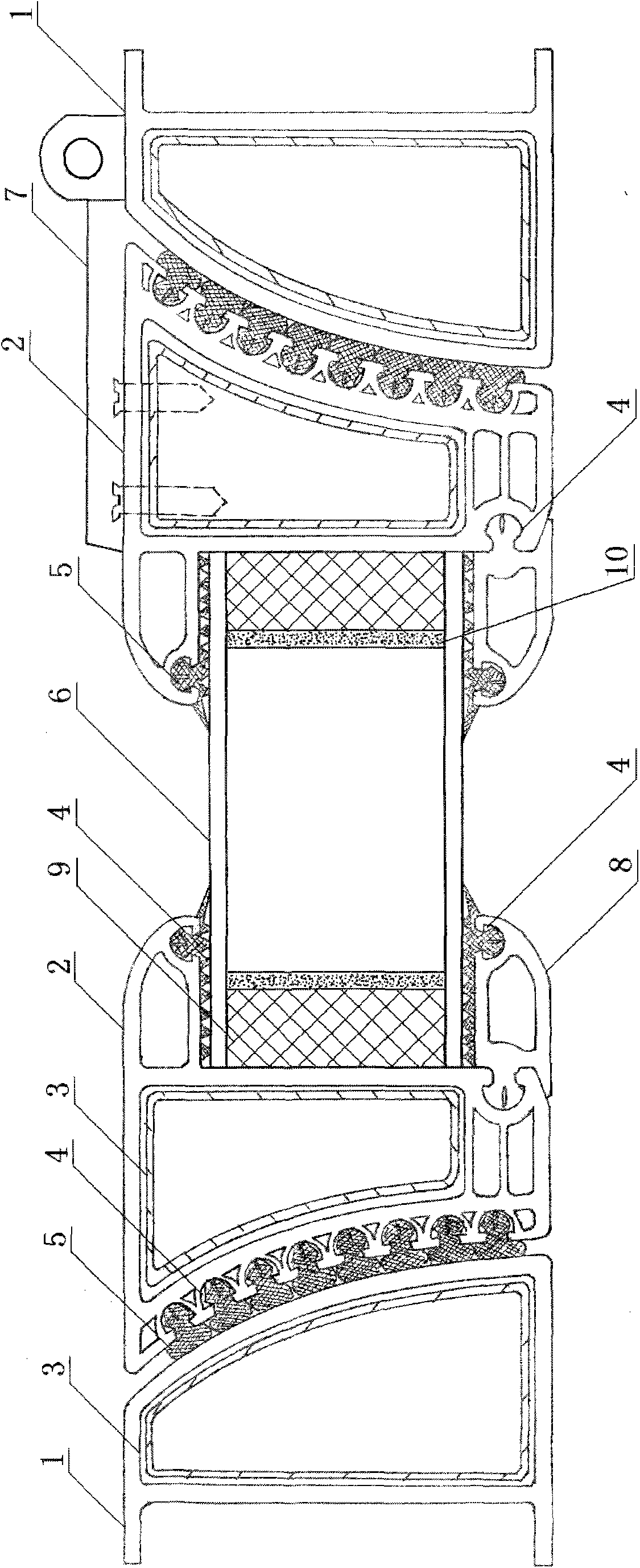

[0005] Below in conjunction with Fig. 1, the full-sealed energy-saving indoor and outdoor casement door of the present invention will be further described. It includes a door leaf and a door frame. The invisible surface of the door leaf material 2 is a concave arc surface, and the invisible surface of the door frame frame material 1 is a convex arc On the outside, a steel lining 3 is arranged inside the door frame material 1 and the door leaf material 2, and 6 to 8 grooves 4 are arranged on the non-visible surface of the door leaf material 2, and a sealing rubber strip 5 is arranged in the groove 4 One side of the door leaf is connected to the door frame through the hinge 7, the door leaf includes glass 6, glass bead 8, sealant strip 5, hollow rubber strip 9, fixed square tube 10 and fan material 2, glass 6 passes through the sealant strip 5 and glass bead 8 Withholding and fixing, the glass 6 is two or three layers, a hollow rubber strip 9 and a fixed square tube 10 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com