Flat-open complete seal plastic steel window

A fully-sealed, plastic-steel window technology, which is applied in the direction of sealing devices, parallel glass structures, and the arrangement of wings, can solve the problems of poor sealing performance and large heat dissipation of plastic-steel doors and windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

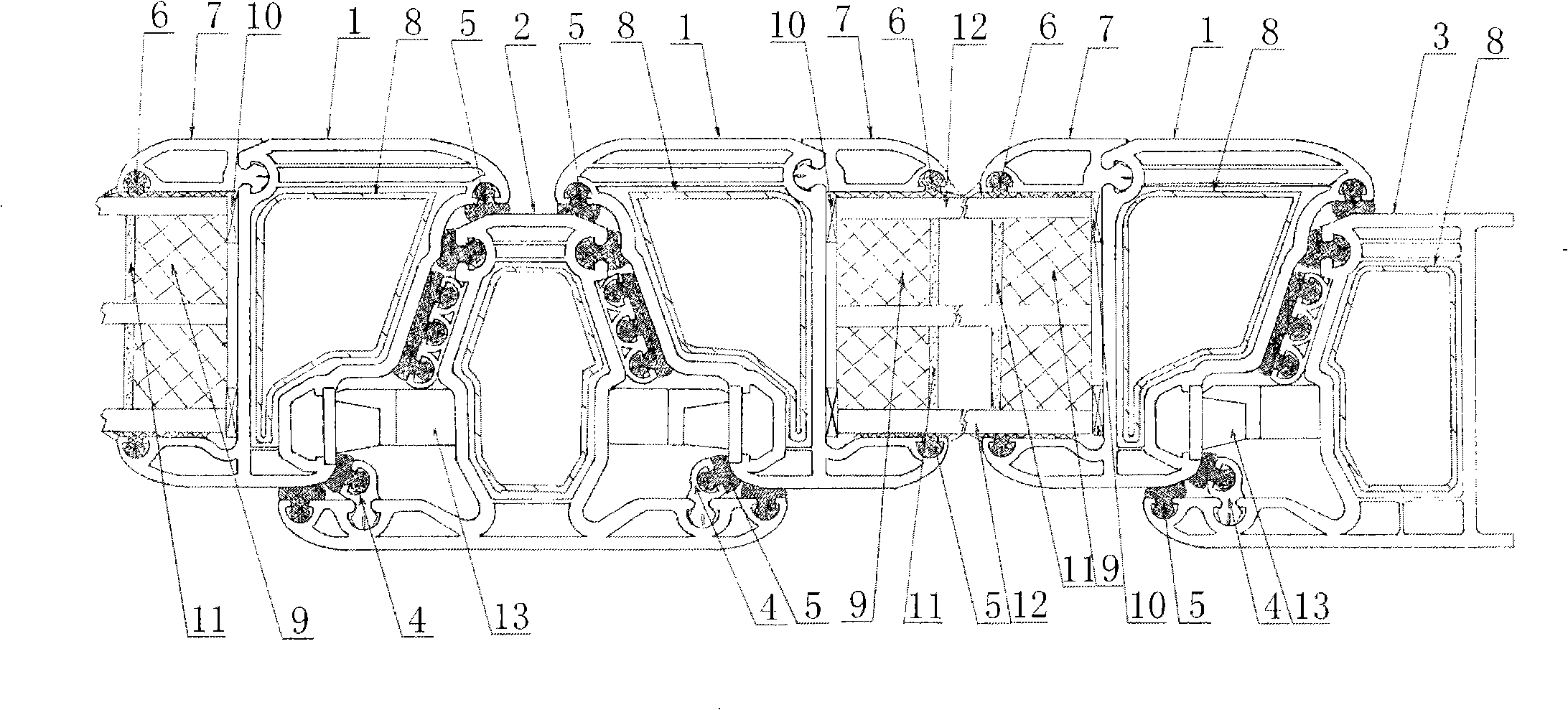

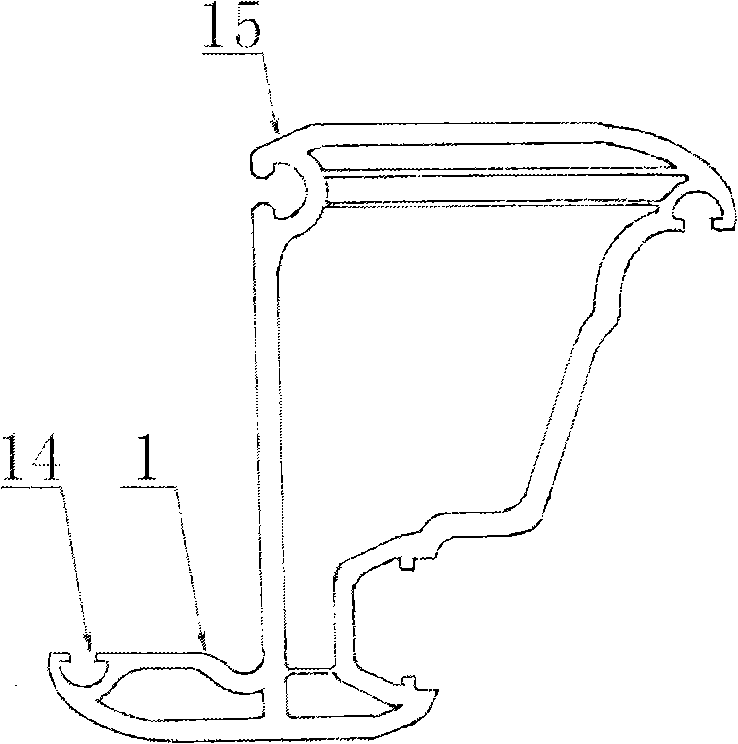

[0021] Embodiment one is combined below figure 1 , image 3 , Figure 5 , Figure 9 , Figure 13 and Figure 14 Further explanation is made on the casement full-sealed plastic-steel window of the present invention, which includes glass 12, glass bead 7, sealing strip 5, fan material 1, stile material 2 and frame material 3, and at the position where glass 12 is to be installed, first put Glass spacer 10, put the cut glass 12 on the glass spacer 10, and then press and fix the glass 12 through the glass sealing strip 6 and the glass bead 7. The non-visible surface of the fan material 1 is composed of an arc surface and an inclined surface. The non-visible surface of fan material 1 overlaps the edge of the non-visible surface of jig material 2 or frame material 3, and cooperates with the bevel surface 15 of fan material 1 and jig material 2 or frame material 3. 2 or between the non-visible surfaces of the frame material 3, a sealing strip support 4 and a sealing strip 5 are ...

Embodiment 2

[0022] Embodiment two is combined below figure 1 , image 3 , Figure 6 , Figure 10 , Figure 13 and Figure 15 Further explanation is made to the casement full-sealed plastic-steel window of the present invention, the above is the same as the first embodiment, and the fan material 1, the stile material 2, the frame material 3 and the sealing strip support 4 are replaced by Figure 6 The stiles 2, Figure 10 frame material 3 and Figure 15 The sealing strip supports 4.

Embodiment 3

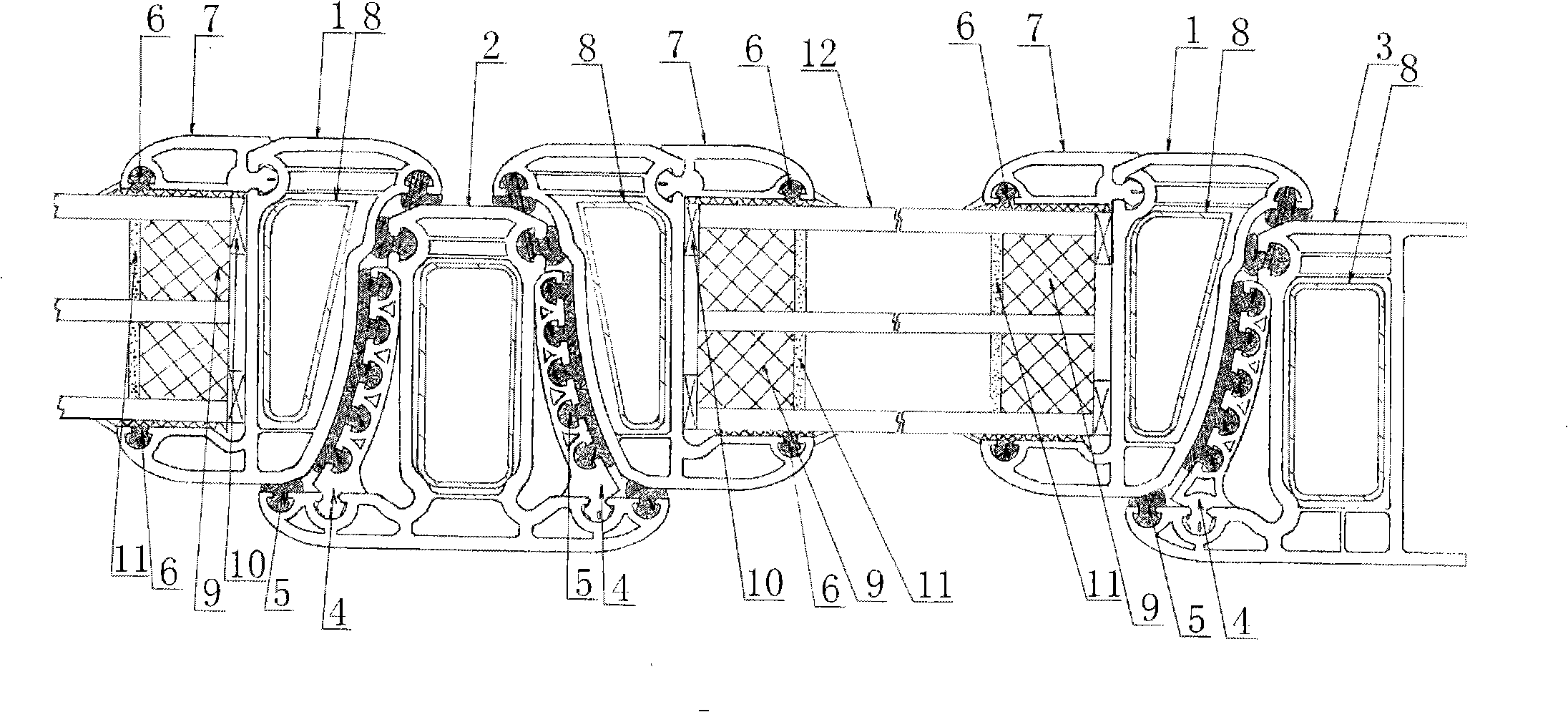

[0023] Embodiment three is combined below figure 2 , Figure 4 , Figure 7 , Figure 11 and Figure 16 Further explanation is made to the casement full-sealed plastic-steel window of the present invention, the above is the same as the first embodiment, the driver 13 is removed, and the fan material 1, the stile material 2, the frame material 3 and the sealing strip support 4 are replaced with Figure 4 fan material 1, Figure 7 The stiles 2, Figure 11 frame material 3 and Figure 16 The sealing strip supports 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com