Method for preparing polyimide/silver composite electrical conductivity fibers

A technology of polyimide and composite conduction, applied in the direction of fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problems of low production efficiency, complicated process, high cost, etc., and achieve high adhesion strength, simple process, and good metallic luster Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

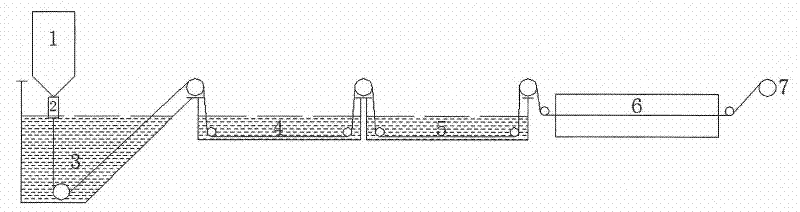

Method used

Image

Examples

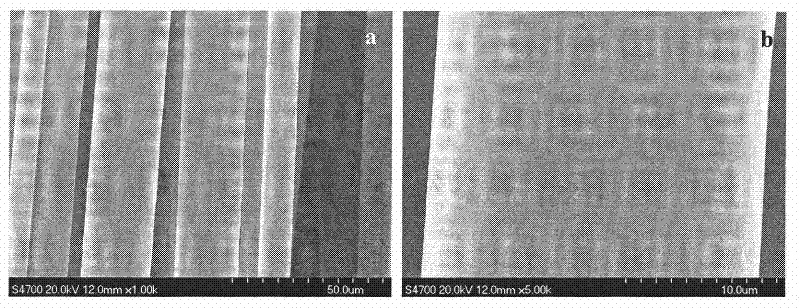

Embodiment 1

[0032] A: The polyamic acid solution with a solid content of 15% PMDA / ODA is used to prepare polyamic acid fibers by wet spinning process;

[0033] B: Pass the polyamic acid fiber prepared in step A through the silver ammonia solution with a concentration of 0.01mol / l at a constant speed under the action of the rotation of the godet for 5 minutes, then wash with water to remove the silver salt attached to the surface, and then Remove the water on the surface of the fiber through a low-temperature heating furnace at a uniform speed. The temperature of the low-temperature heating furnace is set at 100°C and the heating time is 10 minutes to obtain fibers with silver polyamic acid on the surface;

[0034]C: Pass the fiber obtained in step B with polyamic acid silver salt on the surface at a constant speed through a high-temperature furnace for silver reduction and imidization of the fiber under the action of a godet roller. The temperature of the high-temperature furnace is 220 ° ...

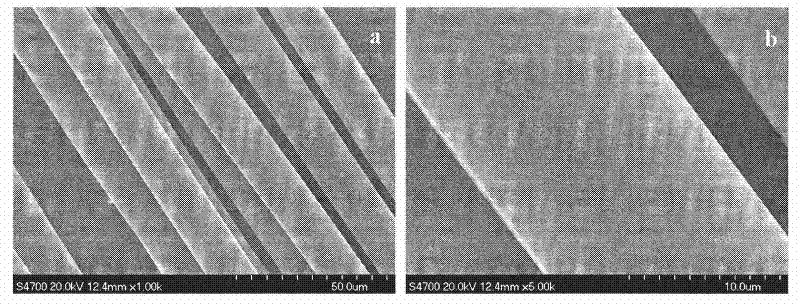

Embodiment 2

[0036] A: The polyamic acid fiber is prepared by using a wet spinning process with a PMDA / ODA polyamic acid solution with a solid content of 20%;

[0037] B: Pass the polyamic acid fiber prepared in step A through the silver nitrate solution with a concentration of 0.001mol / l at a constant speed under the action of the rotation of the godet for 10 minutes, then wash with water to remove the silver salt attached to the surface, and then Remove the water on the surface of the fiber through a low-temperature heating furnace at a uniform speed. The temperature of the low-temperature heating furnace is set at 180°C, and the heating time is 5 minutes to obtain fibers with silver polyamic acid on the surface;

[0038] C: Pass the fiber obtained in step B with the surface of polyamic acid silver salt through a high-temperature furnace at a constant speed under the action of a godet roll to reduce silver and imidize the fiber. The temperature of the high-temperature furnace is 350 ° C, ...

Embodiment 3

[0040] A: The polyamic acid fiber is prepared by using a wet spinning process with a PMDA / ODA polyamic acid solution with a solid content of 25%;

[0041] B: Pass the polyamic acid fiber prepared in step A through the silver nitrate solution with a concentration of 0.0001mol / l at a constant speed under the action of the rotation of the godet for 20 minutes, then wash with water to remove the silver salt attached to the surface, and then Remove the water on the surface of the fiber through a low-temperature heating furnace at a uniform speed. The temperature of the low-temperature heating furnace is set at 200 ° C, and the heating time is 3 minutes to obtain fibers with silver polyamic acid on the surface;

[0042] C: Pass the fiber obtained in step B with polyamic acid silver salt on the surface at a constant speed through a high-temperature furnace to reduce silver and imidize the fiber. The temperature of the high-temperature furnace is 400 ° C, and Keep it for 1 hour to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com