Light-duty high-temperature-resistant and high-specific-surface-area polyimide conductive pulp and preparation method therefor

A polyimide pulp, high specific surface area technology, used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Resistant to bending and other problems, to achieve the effect of high specific surface area, small equipment investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a light-weight, high-temperature-resistant, high-specific-surface-area polyimide conductive pulp and a preparation method thereof, the method comprising:

[0026] (1) Get polyamic acid fiber pulp and disperse evenly in deionized water;

[0027] (2) add ammoniacal liquor to the dispersion liquid of step (1), settle out after keeping certain hour, clean;

[0028] (3) adding the pulp obtained in step (2) into the metal salt solution, settling out after keeping for a certain period of time, and cleaning;

[0029] (4) placing the pulp obtained in step (3) in a reducing solution, keeping it for a certain period of time, and then settling out and cleaning;

[0030] (5) repeat steps (3) and (4) to obtain the polyamic acid pulp with metal layer on the surface;

[0031] (6) Heating the pulp obtained in step (5) to obtain polyimide pulp with a metal layer on the surface.

[0032] According to the method of the present invention, preferably:

[0033] In s...

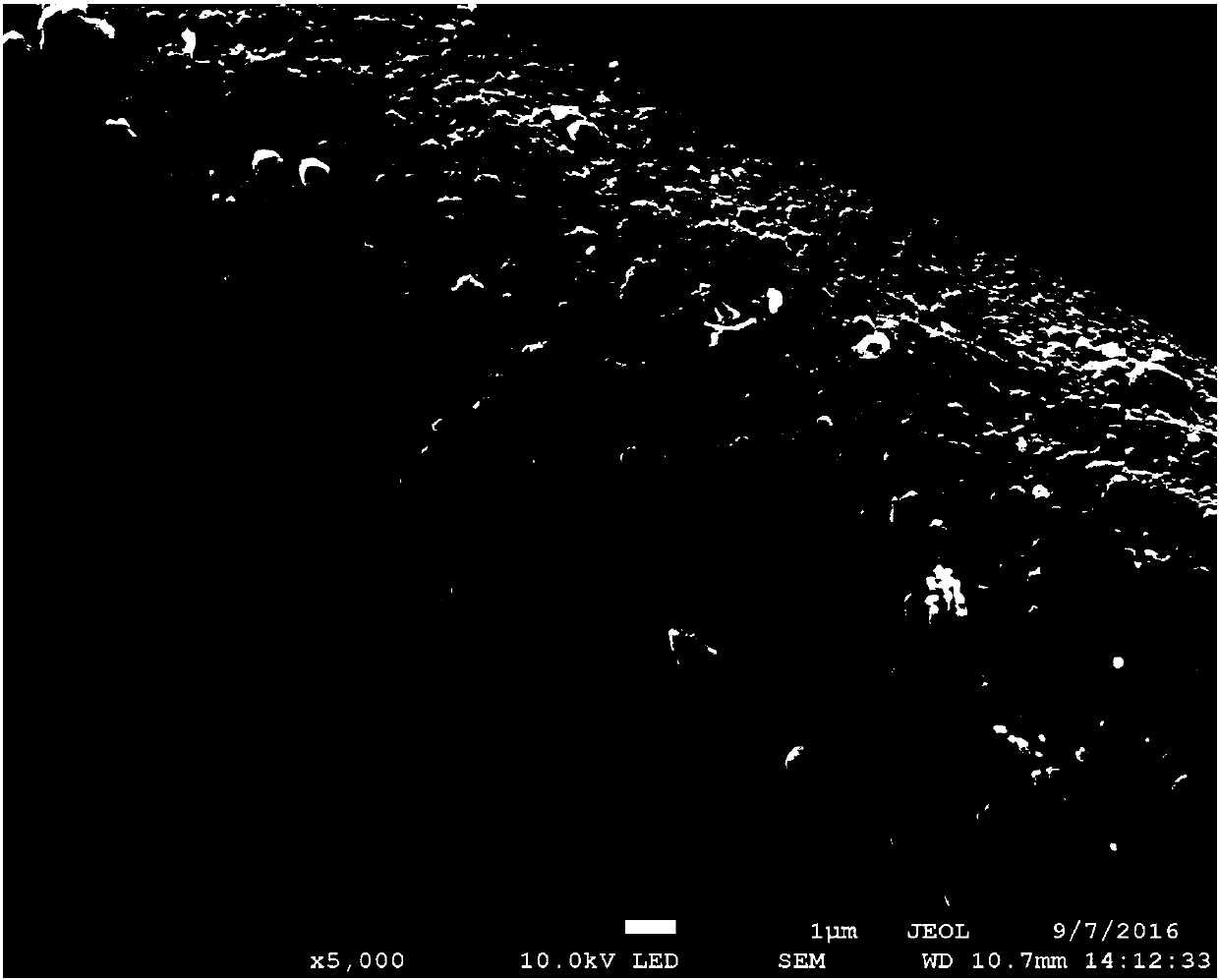

Embodiment 1

[0044] This embodiment is used to illustrate one polyimide conductive pulp material and its preparation method of the present invention.

[0045] (1) Take 1g of polyamic acid fiber pulp and evenly disperse it in 100mL of deionized water;

[0046] (2) Add 1 mL of ammonia water to the dispersion in step (1) for 30 seconds at room temperature to form an organic ammonium salt on the pulp surface;

[0047] (3) adding the pulp obtained in step (2) to 35°C, 0.01M silver ammonia solution;

[0048] (4) placing the pulp obtained in step (3) at 35°C in a 0.5M glucose solution;

[0049] (5) repeating steps (3) and (4) 10 times can obtain the polyamic acid pulp with silver layer on the surface;

[0050] (6) The pulp obtained in step (5) is raised from room temperature to 350° C. at a heating rate of 10° C. / min.

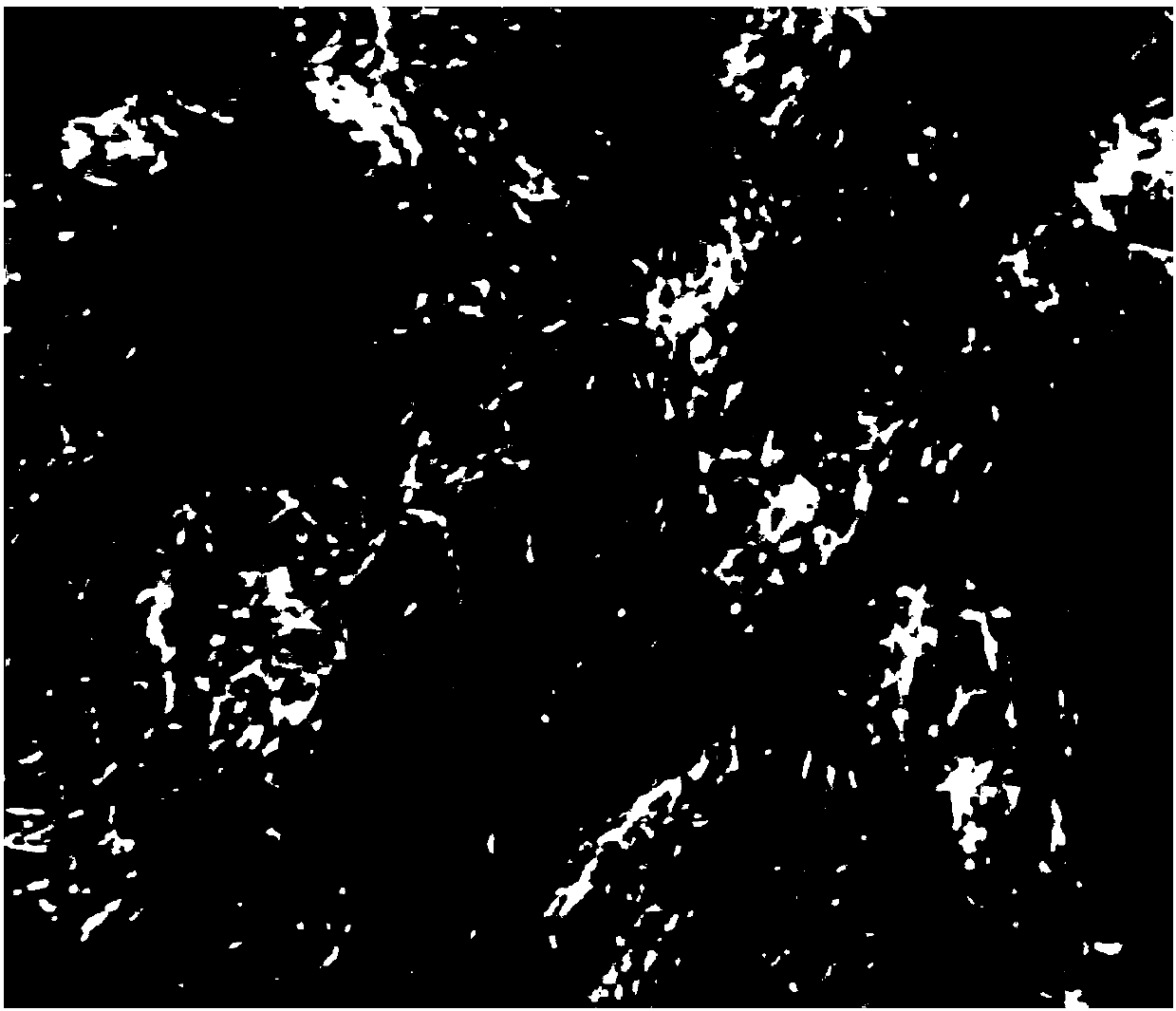

Embodiment 2

[0052] This embodiment is used to illustrate one polyimide conductive pulp material and its preparation method of the present invention.

[0053] (1) Take 1g of polyamic acid fiber pulp and evenly disperse it in 100mL of deionized water;

[0054] (2) Add 1 mL of ammonia water to the dispersion in step (1) for 30 seconds at room temperature to form an organic ammonium salt on the pulp surface;

[0055] (3) adding the pulp obtained in step (2) to 35°C, 0.01M silver ammonia solution;

[0056] (4) placing the pulp obtained in step (3) at 35°C in 1M glucose solution;

[0057] (5) repeating steps (3) and (4) 10 times can obtain the polyamic acid pulp with silver layer on the surface;

[0058] (6) The pulp obtained in step (5) is raised from room temperature to 350° C. at a heating rate of 10° C. / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com