Graphene film preparation method

A graphene film and graphene technology, applied in the preparation of graphene film, improving the electrical and thermal conductivity of graphene film, can solve the problems such as difficult to achieve continuous, high polyimide film, heteroatom overflow, etc., to achieve Improve the crystal structure of graphene film, reduce square resistance, and improve the effect of electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

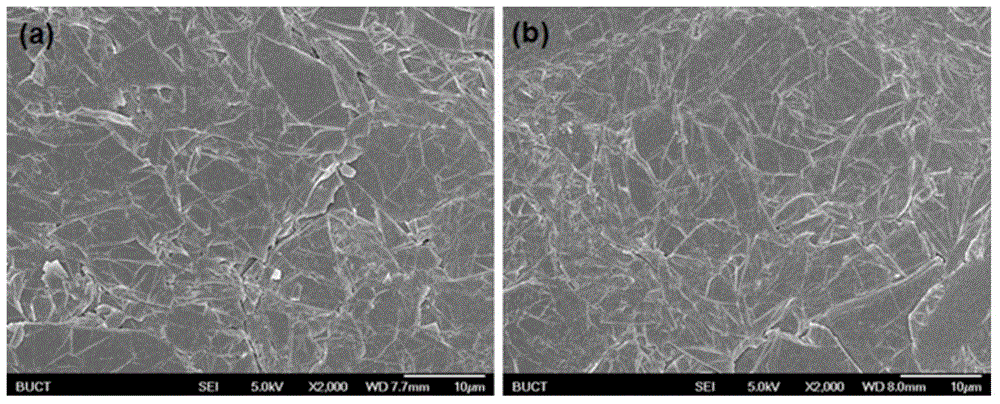

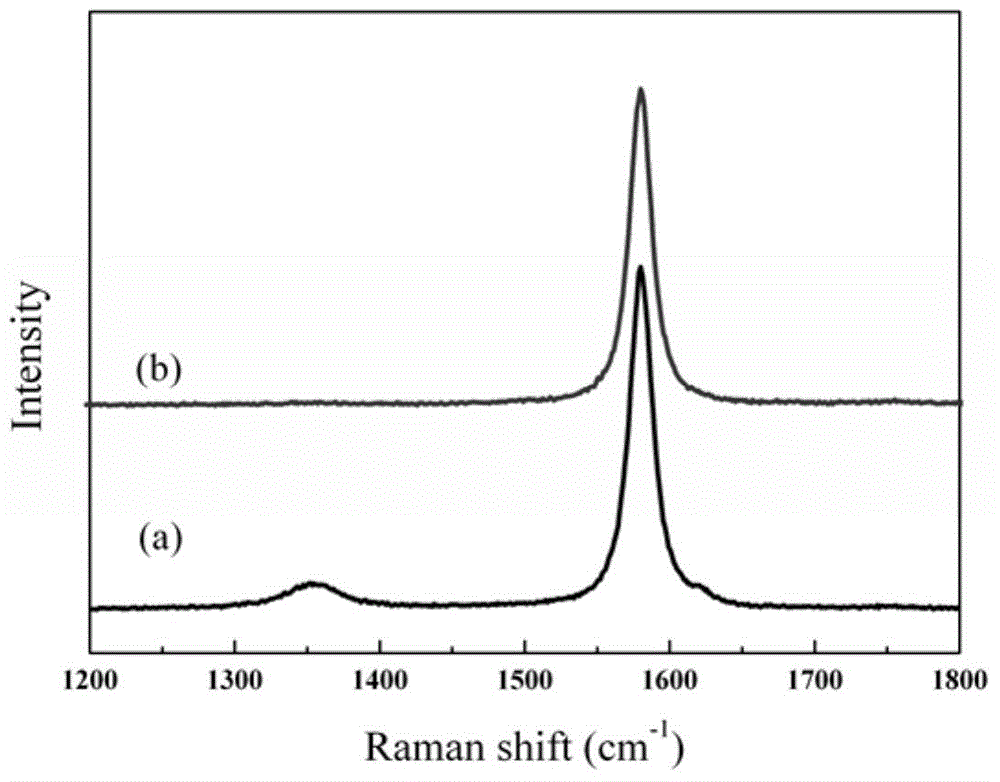

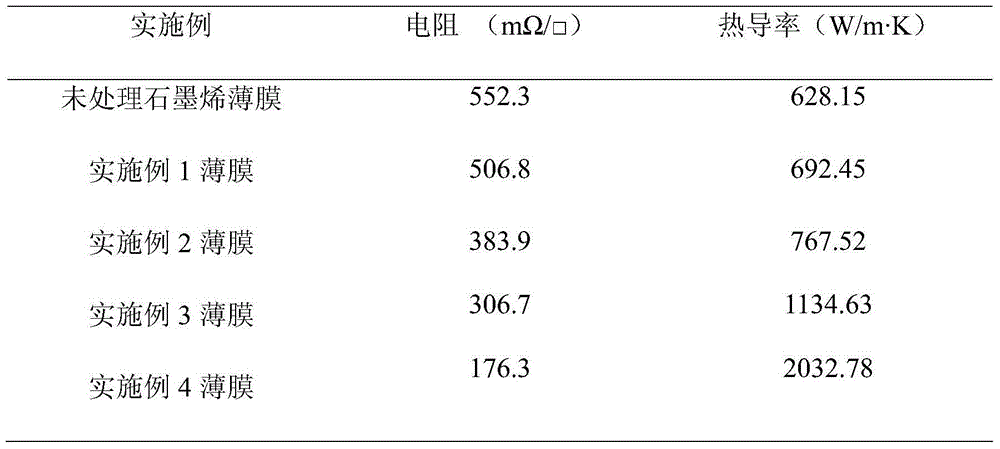

[0020] Sprinkle the graphene powder evenly on the paper base, plastic base film or steel belt that is fixed or moving forward at a constant speed, and then rolled by multiple rollers, the powder is pressed into a film by mechanical force; the pressed film is placed in a graphite furnace in N 2 High temperature treatment under gas protection, N 2 The flow rate is 200ml / min, the temperature is raised to 1000°C at a heating rate of 10°C / min, and the final temperature is kept for 60 minutes. After the end, it is naturally cooled to obtain a graphene film with high electrical and thermal conductivity, and the film thickness is 33.8 μm.

Embodiment 2

[0022] Sprinkle the graphene powder evenly on the paper base, plastic base film or steel belt that is fixed or moving forward at a constant speed, and then through multi-roller rolling, the powder is mechanically pressed into a film, and the pressed film is placed on graphite in the furnace; in N 2 High temperature treatment under gas protection, N 2 The flow rate is 200ml / min, the temperature is raised to 1500°C at a heating rate of 10°C / min, and the final temperature is kept for 60 minutes. After the end, it is naturally cooled to obtain a graphene film with high electrical and thermal conductivity, and the film thickness is 33.8 μm.

Embodiment 3

[0024] Sprinkle the graphene powder evenly on the paper base, plastic base film or steel belt that is fixed or moving forward at a constant speed, and then through multi-roller rolling, the powder is mechanically pressed into a film, and the pressed film is placed on graphite In the furnace; high temperature treatment is carried out under the protection of argon gas, the argon gas flow rate is 200ml / min, the temperature is raised to 2000°C at a heating rate of 10°C / min, and the final heat preservation is 60min, and after the end, it is naturally cooled to obtain high electrical and thermal conductivity. Graphene film with a film thickness of 33.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com