Polyimide nano-fiber membrane with crosslinked structure and preparation thereof

A nanofiber membrane, polyimide technology, applied in the direction of chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc. problems, to achieve the effect of widening varieties, easy flow, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A. Using the polyamic acid solution obtained by polycondensation of BPDA / pPDA, the polyamic acid nanofiber membrane was prepared by electrospinning.

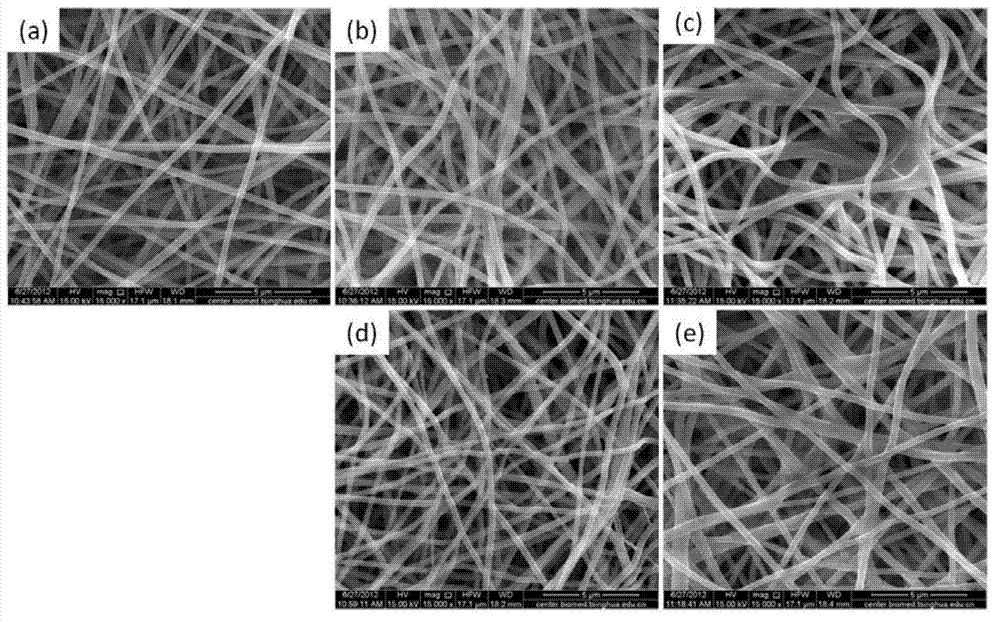

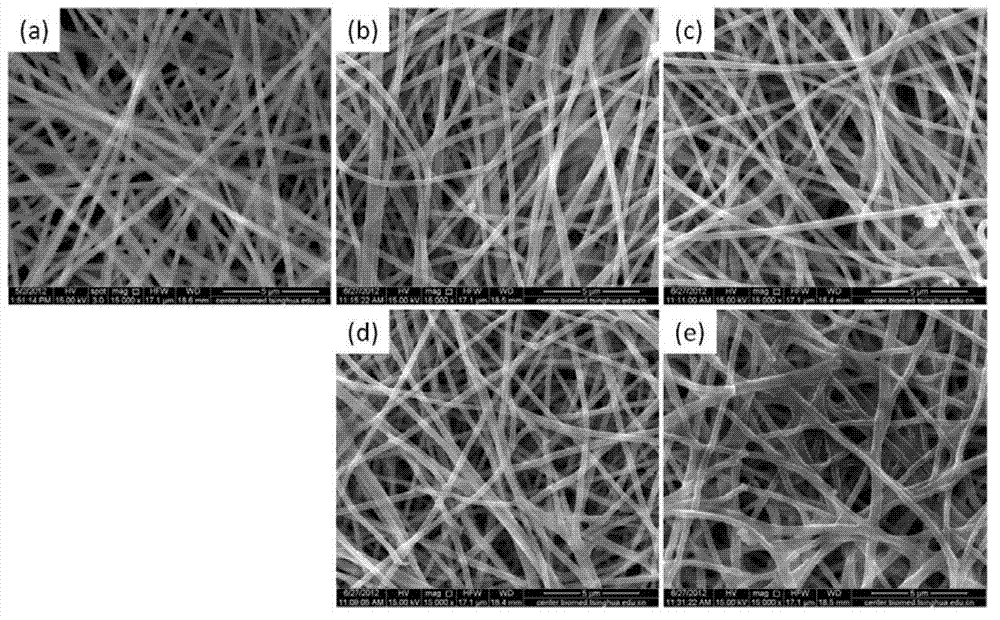

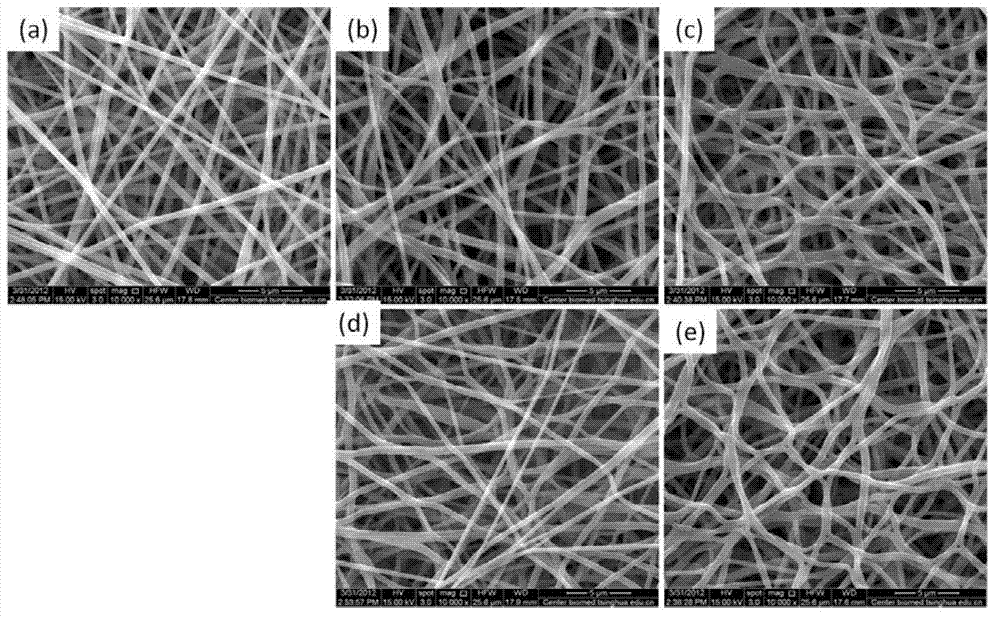

[0037] B. After 2.5*10 -3 Soak in wt% ammonia water for 10s, then fully wash with deionized water, and after vacuum drying, use gradient thermal imidization process to imidize to prepare polyimide nanofiber membrane. The morphology of the obtained fiber membrane is shown in the attached figure 1 (b) shown.

Embodiment 2

[0039] A. Using the polyamic acid solution obtained by polycondensation of BPDA / pPDA, the polyamic acid nanofiber membrane was prepared by electrospinning.

[0040] B. After 2.5*10 -3 wt% ammonia water soaked for 60s, then fully cleaned with deionized water, and dried in vacuum, and then imidized by gradient thermal imidization process to prepare a polyimide nanofiber membrane. The morphology of the obtained fiber membrane is as shown in the attached figure 1 (c) shown.

Embodiment 3

[0042] A. Using the polyamic acid solution obtained by polycondensation of BPDA / pPDA, the polyamic acid nanofiber membrane was prepared by electrospinning.

[0043] B. Soak in 0.125wt% ammonia water for 10s, then fully wash with deionized water, and vacuum-dry, then adopt gradient thermal imidization process to carry out imidization to prepare polyimide nanofiber membrane, the obtained fiber membrane Looks like figure 1 (d) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com