Method for preparing submicron polyimide self-supporting film by adopting spin-coating method

A technology of self-supporting film and polyimide, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., can solve the problem of low efficiency of supporting polyimide film, easy cracking of the film, warping of the film To solve the problems of bubbling experiment, simplify the bubbling test device, high yield, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A: In an ice bath environment, use a magnet to provide stirring. First weigh 0.27035g of p-phenylenediamine and add it to a three-necked flask, then add 20ml of N,N-dimethylacetamide, stir until completely dissolved, then add 0.73898g of 3,3',4,4'-biphenyltetracarboxylic acid Dianhydride, continue to stir for about 6 hours to a uniform curd-like viscous substance, take it out and put it in the refrigerator for later use;

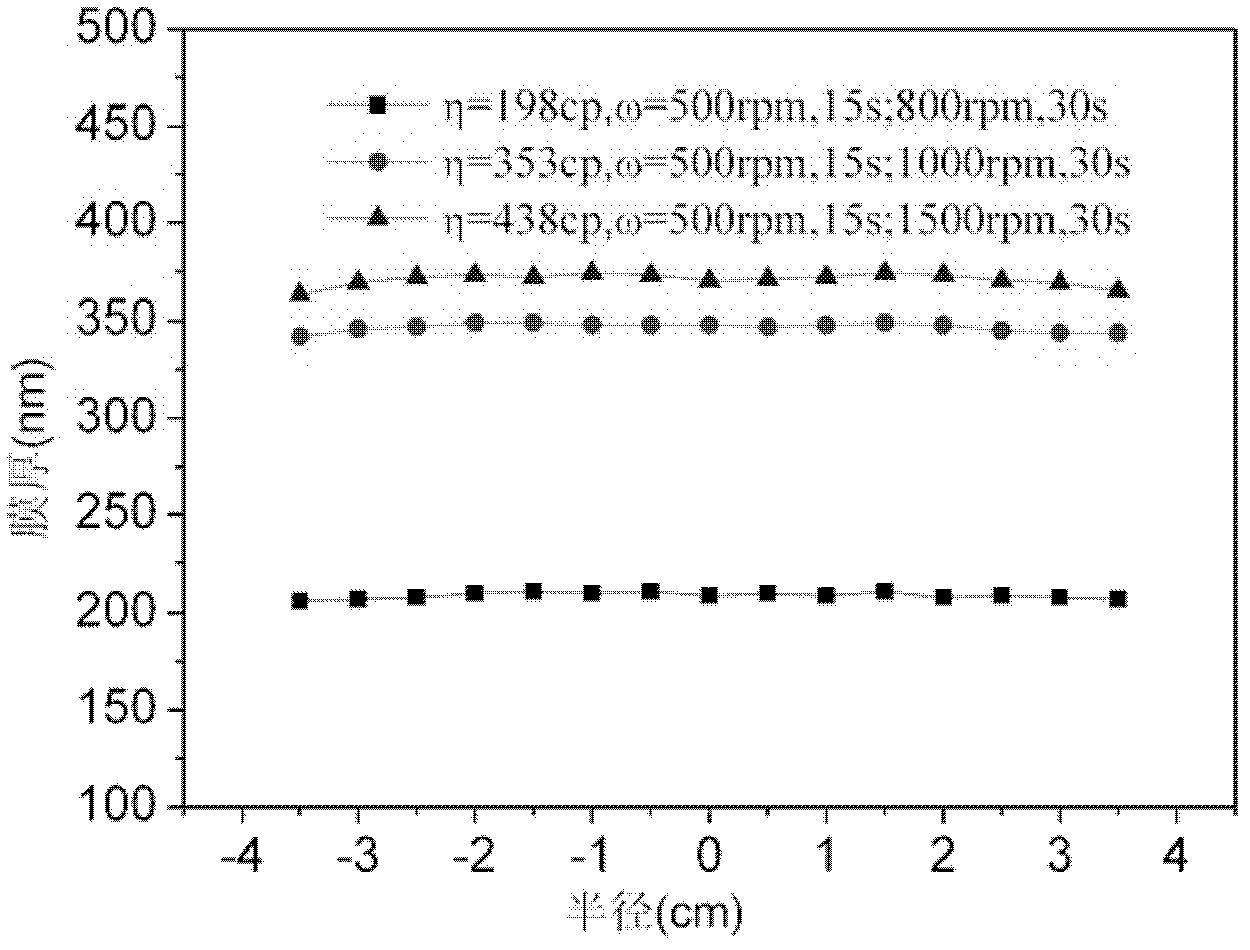

[0038] B: Dilute the polyamic acid solution in step A to 438cp with N,N-dimethylacetamide, filter it with a microporous filter, leave it for a period of time until the bubbles in the solution are completely eliminated, and then use step-by-step spinning Spin-coat polyamic acid solution on a 4-inch clean silicon wafer, the spin-coating parameter is 500rpm for 15s, and then 1500rpm for 30s, (or two other schemes: if diluted to 353cp, the spin-coating parameter is 500rpm for 15s , then 1000rpm for 30s; or if diluted to 198cp, spin coating parameters are ...

Embodiment 2

[0044] A: In an ice bath environment, use a magnet to provide stirring. First weigh 0.5006g of 4,4'-diaminodiphenyl ether into a three-necked flask, then add 20ml of N,N-dimethylacetamide, stir until completely dissolved, then add 0.54803g of pyromellitic dianhydride, continue Stir for about 6 hours to a uniform curd-like viscous substance, take it out and put it in the refrigerator for later use;

[0045] B: Dilute the polyamic acid solution in step A to 760cp, filter it with a microporous filter, leave it for a period of time until the bubbles in the solution are completely eliminated, and use the step-by-step spin coating method on a clean float with a diameter of 8cm The polyamic acid solution was spin-coated on the glass, and then the polyamic acid solution was further diluted and spin-coated to prepare polyamic acid films under three different conditions: ①760cp, 2500rpm②288cp, 1000rpm③288cp, 1500rpm;

[0046] C: Pre-baking the polyamic acid gel film prepared by the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com