Shampoo soap and production method thereof

A production method and soap technology, applied in chemical instruments and methods, soap detergents and other compounding agents, hair care, etc., can solve the problems that shampoo has little cleaning effect on the body, soap cannot achieve the effect of shampoo, and achieve hair care And the effect of protecting hair, safe processing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

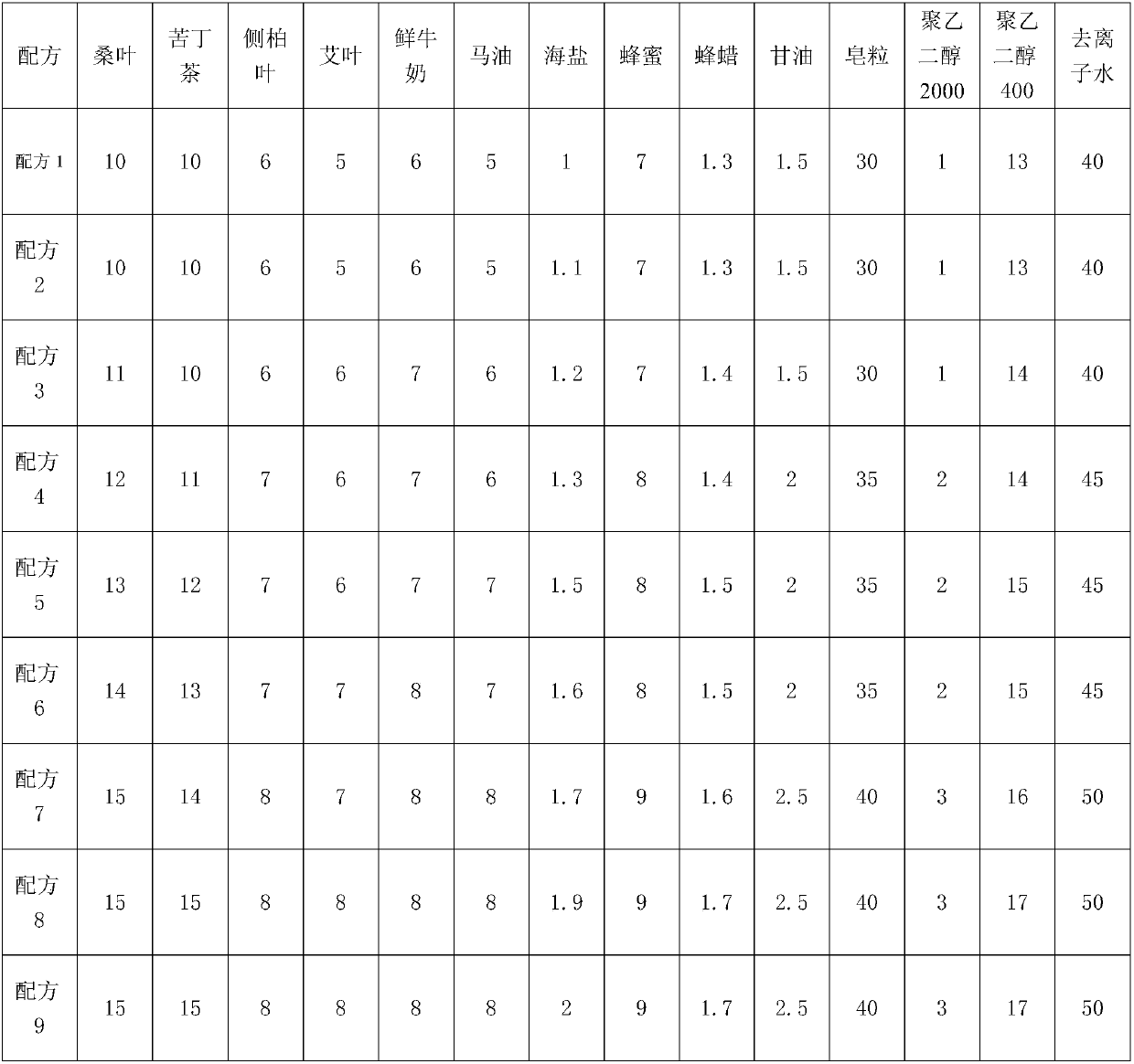

[0025] Embodiment 1 soap processing formula

[0026]

[0027] Above formula is calculated by weight.

Embodiment 2

[0028] Embodiment 2 scented soap production method (1)

[0029] The scented soap produced by the present invention can adopt the formula selection material in example 1: 10 parts of mulberry leaves; 10 parts of Kudingcha; 6 parts of arborvitae leaves; 5 parts of Artemisia argyi; 6 parts of fresh milk; 5 parts of horse oil; 7 parts; 1.3 parts of beeswax; 1.5 parts of glycerin; 30 parts of soap grains; 1 part of polyethylene glycol 2000; 13 parts of polyethylene glycol 400; 40 parts of deionized water.

[0030] Produce according to the following production methods:

[0031] (1) Get quantitative mulberry leaves, kudingcha, arborvitae leaves and Artemisia arborvitae, wash and set aside;

[0032] (2) Treat mulberry leaves, kudingcha, and arborvitae leaves, add water and heat respectively, the temperature is 90°C, after boiling, reduce the temperature to 50°C, stop heating when each liquid medicine becomes thicker;

[0033] (3) Mix the mulberry leaf, kudingcha, and arborvitae leaf...

Embodiment 3

[0041] Embodiment 3 scented soap production method (2)

[0042] The scented soap produced by the present invention can adopt the formula selection material in example 1: 13 parts of mulberry leaves; 12 parts of Kudingcha; 4 parts of Arborvitae leaves; 6 parts of Artemisia argyi; 7 parts of fresh milk; 7 parts of horse oil; 1.5 parts of sea salt; 8 parts; 1.5 parts of beeswax; 2 parts of glycerin; 35 parts of soap grains; 2 parts of polyethylene glycol 2000; 15 parts of polyethylene glycol 400; 45 parts of deionized water.

[0043] Produce according to the following production methods:

[0044] (1) Get quantitative mulberry leaves, kudingcha, arborvitae leaves and Artemisia arborvitae, wash and set aside;

[0045] (2) Treat mulberry leaves, kudingcha, and arborvitae leaves, add water and heat respectively, the temperature is 95°C, after boiling, reduce the temperature to 55°C, and stop heating when the liquid medicines become thicker;

[0046] (3) Mix the mulberry leaf, kudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com