MWT and passivation combined crystal silicon solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as low-cost mass-producible structures and preparation methods that have not yet appeared, and achieve the effect of being beneficial to removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

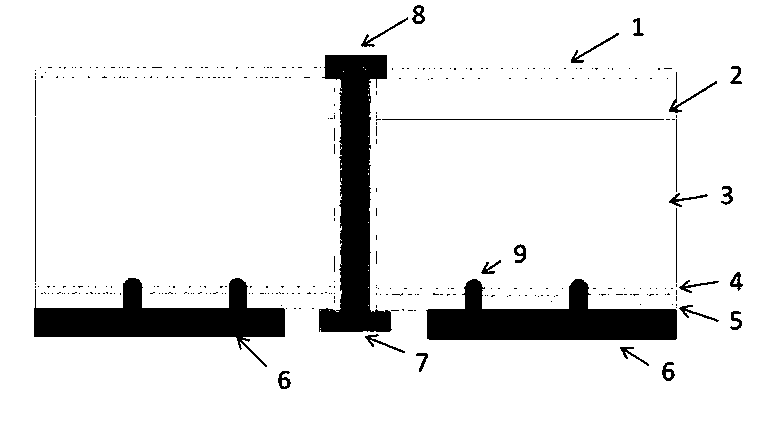

[0033] Embodiment: the structure of the crystalline silicon solar cell that the MWT of this embodiment combines with back passivation is as follows figure 1 As shown, it includes an antireflection film 1, a phosphorus diffusion layer 2, a P-type silicon substrate 3, an aluminum oxide film 4, a laminated protective film 5, and an aluminum printing layer 6 that are sequentially stacked. It is equipped with a silver electrode 7 for the filling hole, and a dielectric film is covered between the hole wall and the silver electrode 7 for the filling hole. A local aluminum back field contact 9 is formed through the lamination protection film 5 and the aluminum oxide film 4 and with the P-type silicon substrate 3 .

[0034] Using a 156mm P-type single crystal silicon wafer as the base material, the specific steps of the manufacturing method are as follows:

[0035] (1) Use a red laser to drill holes on the back of the silicon wafer, the pattern is a 4*4 matrix, the diameter of the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com