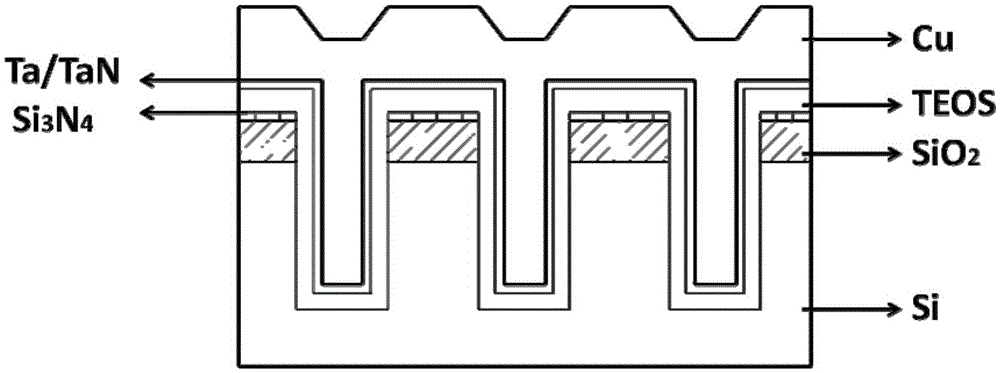

Method for improving copper film thickness consistency during alkaline CMP of GLSI silicon through holes

A technology of copper film thickness and consistency, which is applied to polishing compositions containing abrasives, grinding devices, grinding machine tools, etc., can solve the unmentioned problems of copper film thickness consistency, reduce damaged layers, facilitate removal, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

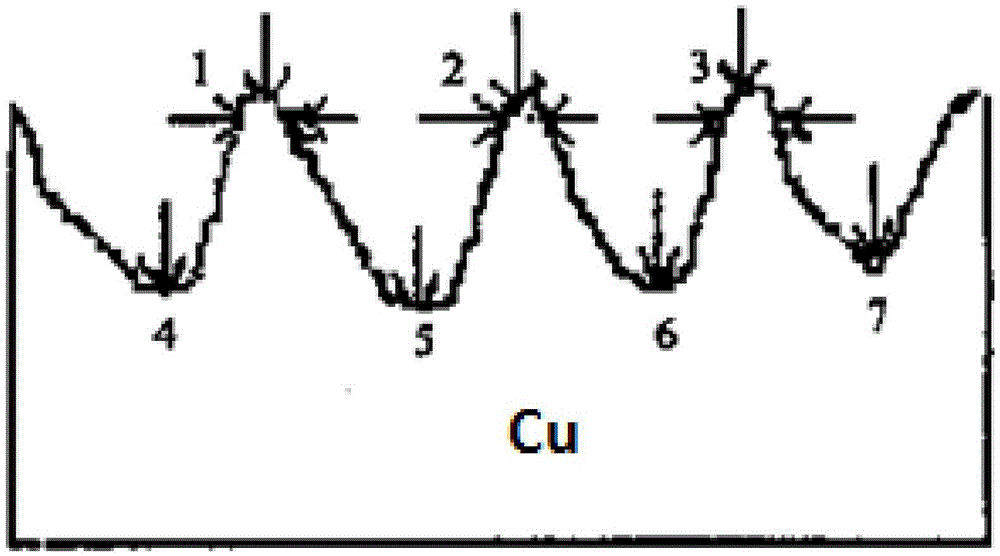

Method used

Image

Examples

Embodiment 1

[0028] Prepare 2kgFA / O polishing solution for chemical mechanical polishing.

[0029] Take 1000g of silica hydrosol with a particle size of 80nm, add 50gFA / OⅡtype chelating agent while stirring, then add 15gFA / OⅠtype surfactant while stirring, then add it into 927.5g of deionized water while stirring, and finally Add 7.5g of hydrogen peroxide while stirring; wipe the polishing piece with absolute alcohol, rinse off the residual alcohol with water, and load the polishing piece on the polishing machine table. Working pressure: 27.4kpa; polishing head / disc speed: 65 / 60rpm; flow rate: 225mL / min, polishing time: 180s. After polishing, take out the polishing sheet, first rinse it with water, then dry the water with nitrogen, put the polishing sheet in a dust-free box and send it to the testing room. The results are: the copper film removal rate is 1.94μm / min; the non-uniformity within the chip is 2.9%.

Embodiment 2

[0031] Prepare 2kgFA / O polishing solution for chemical mechanical polishing.

[0032] Take 1000g of silica hydrosol with a particle size of 80nm, add 50gFA / OⅡtype chelating agent while stirring, then add 15gFA / OⅠtype surfactant while stirring, then add it into 927.5g of deionized water while stirring, and finally Add 7.5g of hydrogen peroxide while stirring; wipe the polishing piece with absolute alcohol, rinse off the residual alcohol with water, and load the polishing piece on the polishing machine table. Working pressure: 27.4kpa; polishing head / disk speed: 85 / 80rpm; flow rate: 225mL / min, polishing time: 180s. After polishing, take out the polishing sheet, first rinse it with water, then dry the water with nitrogen, put the polishing sheet in a dust-free box and send it to the testing room. The results are: the copper film removal rate is 1.92μm / min; the non-uniformity within the chip is 3.2%.

Embodiment 3

[0034] Prepare 2kgFA / O polishing solution for chemical mechanical polishing.

[0035]Take 1000g of silica hydrosol with a particle size of 80nm, add 50gFA / OⅡtype chelating agent while stirring, then add 15gFA / OⅠtype surfactant while stirring, then add it into 927.5g of deionized water while stirring, and finally Add 7.5g of hydrogen peroxide while stirring; wipe the polishing piece with absolute alcohol, rinse off the residual alcohol with water, and load the polishing piece on the polishing machine table. Working pressure: 27.4kpa; polishing head / disk speed: 105 / 100rpm; flow rate: 225mL / min, polishing time: 180s. After polishing, take out the polishing sheet, first rinse it with water, then dry the water with nitrogen, put the polishing sheet in a dust-free box and send it to the testing room. The results are: the copper film removal rate is 1.91μm / min; the non-uniformity within the chip is 3.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com