Protection method for anodic oxidation of aluminum-stainless steel compounded cooker

A kind of anodic oxidation, stainless steel technology, applied in the direction of anodic oxidation, etc., can solve the problems such as difficult removal, stainless steel pitting corrosion, etc., and achieve the effect of easy operation, simple operation and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

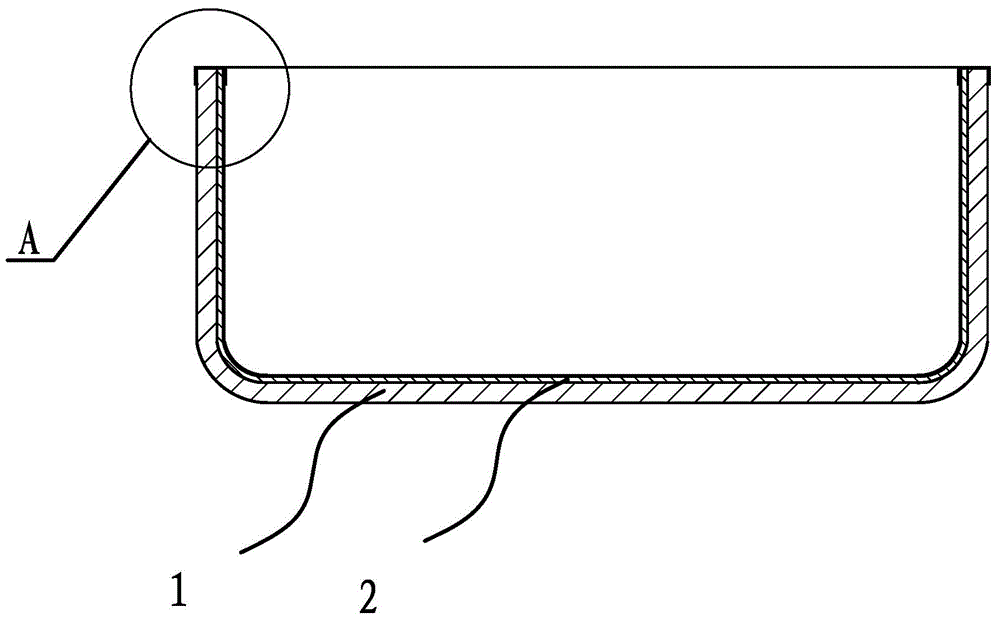

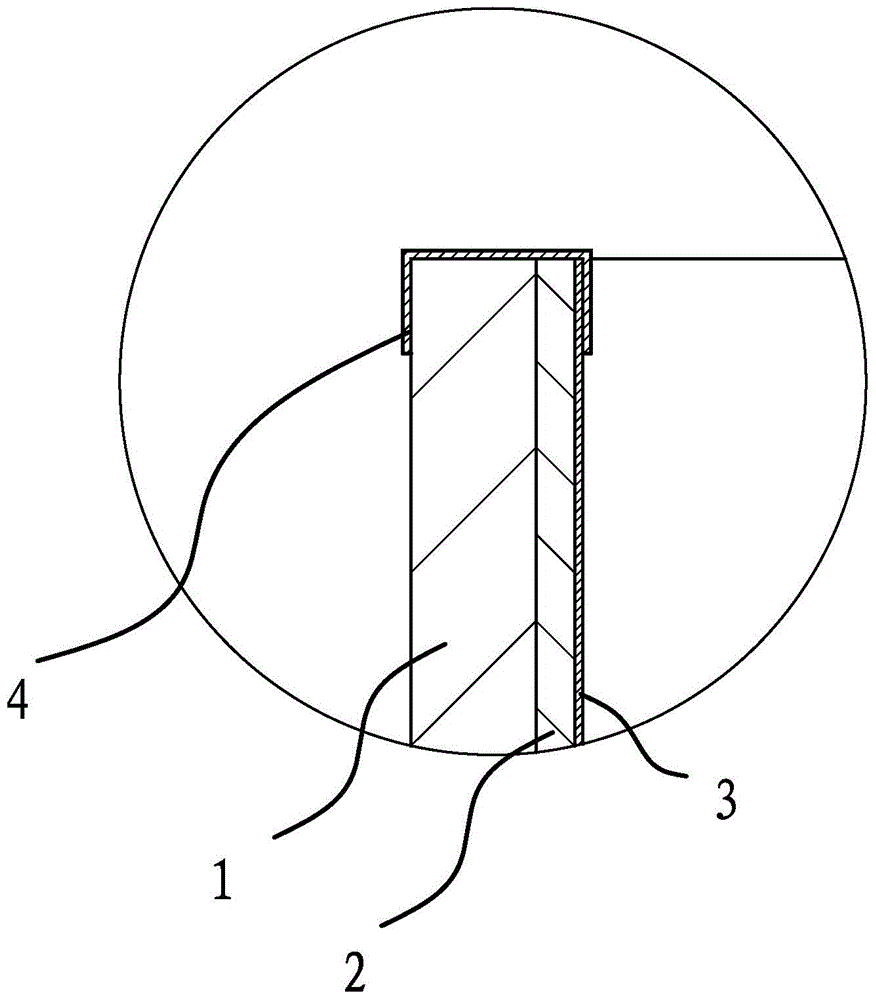

[0035] The aluminum-stainless steel composite cooker of the present embodiment is a conventional cooker in the art, such as figure 1 and figure 2 As shown, the aluminum-stainless steel composite cooker of this embodiment includes an aluminum alloy body 1 and a stainless steel sheet 2, and the aluminum alloy body 1 and the stainless steel sheet 2 are combined into one body, such as using stamping to make the aluminum alloy body 1 and the stainless steel sheet 2 combined into one.

[0036] Processing and forming the aluminum-stainless steel composite material to make a corresponding aluminum-stainless steel composite cookware workpiece; the forming can be processed by deep drawing, spinning, extrusion or cutting;

[0037] The aluminum-stainless steel composite cookware workpiece made above is deburred, trimmed, or subjected to mechanical treatment such as sanding, polishing and polishing, and chemical pretreatment such as degreasing. This type of process is a conventional pro...

Embodiment 2

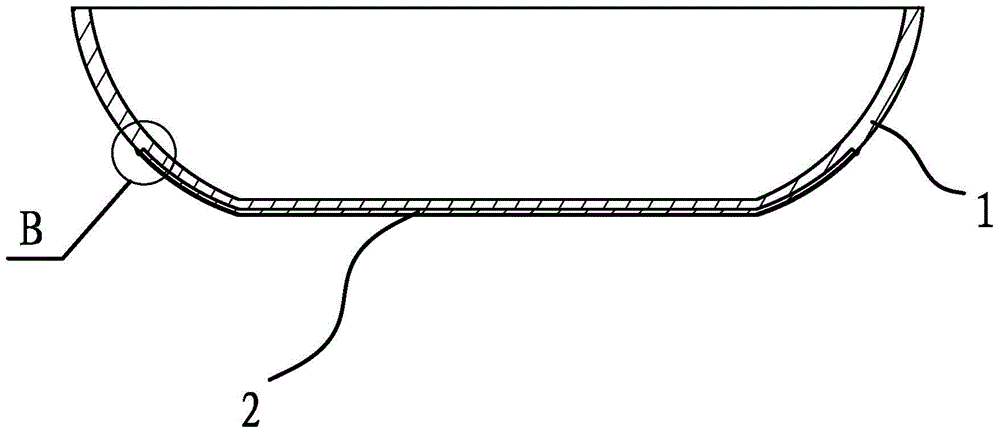

[0043] The aluminum-stainless steel composite cooker of the present embodiment is a conventional cooker in the art, such as image 3 and Figure 4 Shown is another aluminum-stainless steel composite cooker, the aluminum-stainless steel composite cooker includes an aluminum alloy body 1 and a stainless steel sheet 2, the aluminum alloy body 1 and the stainless steel sheet 2 are composited as one, such as by stamping The aluminum alloy body 1 and the stainless steel sheet 2 are combined into one.

[0044] Processing and forming the aluminum-stainless steel composite material to make a corresponding aluminum-stainless steel composite cookware workpiece; the forming can be processed by deep drawing, spinning, extrusion or cutting;

[0045] The aluminum-stainless steel composite cookware workpiece made above is deburred, trimmed, or subjected to mechanical treatment such as sanding, polishing and polishing, and chemical pretreatment such as degreasing. This type of process is a c...

Embodiment 3

[0051] The aluminum-stainless steel composite cooker of the present embodiment is a conventional cooker in the art, such as figure 1 figure 2 As shown, the aluminum-stainless steel composite cooker of this embodiment includes an aluminum alloy body 1 and a stainless steel sheet 2, and the aluminum alloy body 1 and the stainless steel sheet 2 are combined into one body, such as using stamping to make the aluminum alloy body 1 and the stainless steel sheet 2 combined into one.

[0052] Processing and forming the aluminum-stainless steel composite material to make a corresponding aluminum-stainless steel composite cookware workpiece; the forming can be processed by deep drawing, spinning, extrusion or cutting;

[0053] The aluminum-stainless steel composite cookware workpiece made above is deburred, trimmed, or subjected to mechanical treatment such as sanding, polishing and polishing, and chemical pretreatment such as degreasing. This type of process is a conventional process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com