Cleaning machine for air cleaner element

An air filter and cleaning machine technology, applied in membrane filter, gas treatment, filter regeneration and other directions, can solve the problems of large environmental pollution, low cleaning efficiency, operator's personal health injury, etc., to avoid pollution, reduce The effect of burden and isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

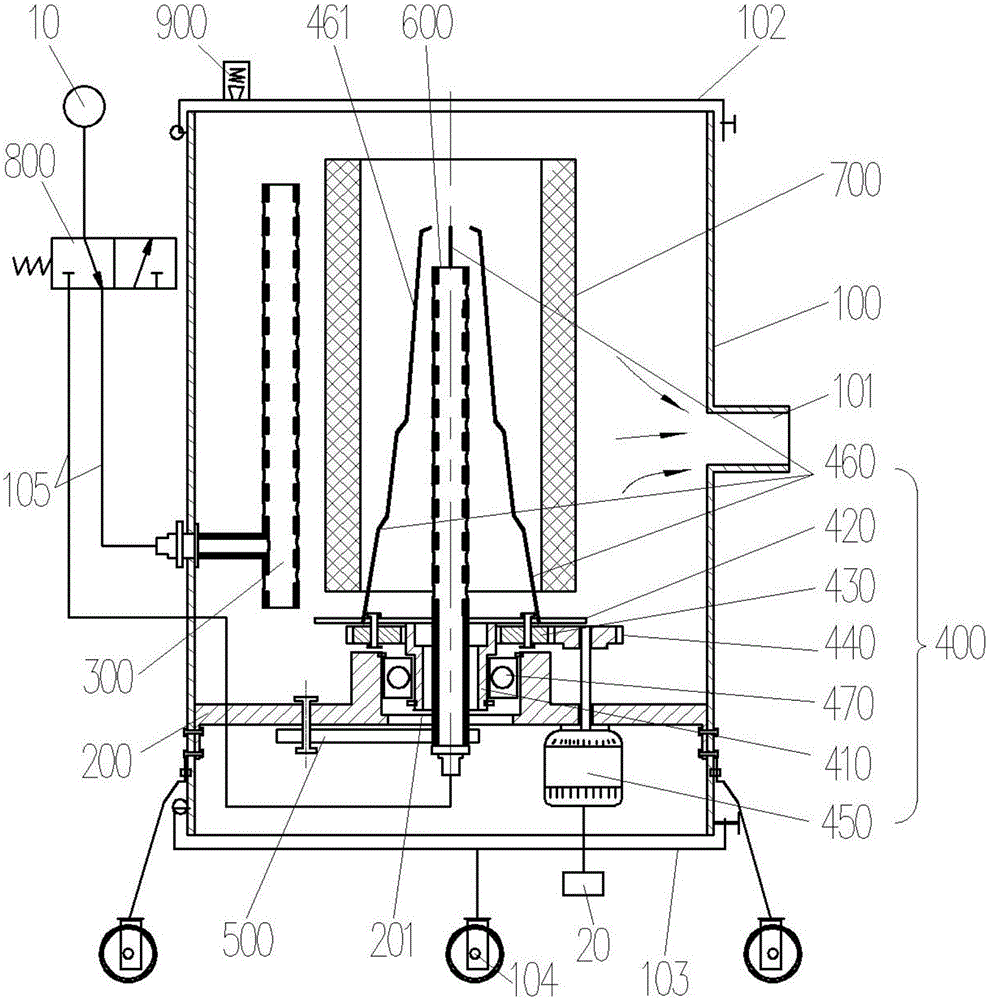

[0026] refer to figure 1 , The air filter element cleaning machine (hereinafter referred to as "cleaning machine") includes a closed cover 100 and a two-position valve 800. The air filter element 700 is in the shape of a ring with dense micropores distributed on the surrounding wall.

[0027] The closed cover body 100 is made of thin-walled plates tightly connected, and a cavity isolated from the outside is formed inside, which avoids the pollution of the outside and the injury of the operator caused by the dirt generated during the cleaning process. The inside of the closed cover 100 is provided with a bottom frame 200 and an external cleaning device 300 which are fixed to the closed cover 100 through screw connections. The blowing port of the external cleaning device 300 faces the outer wall of the air filter element 700 to ensure good gas force and cleaning efficiency.

[0028] The bottom frame 200 is provided with a stepped through hole 201 with a stepped surface, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com