Method for preparing graphene material by microwave irradiation in vacuum or inert gas environment

A technology of microwave irradiation and inert gas, applied in the direction of graphene, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of graphene being easy to burn, low final yield, and causing fire hazards , to achieve simple equipment, increase productivity, and avoid burning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

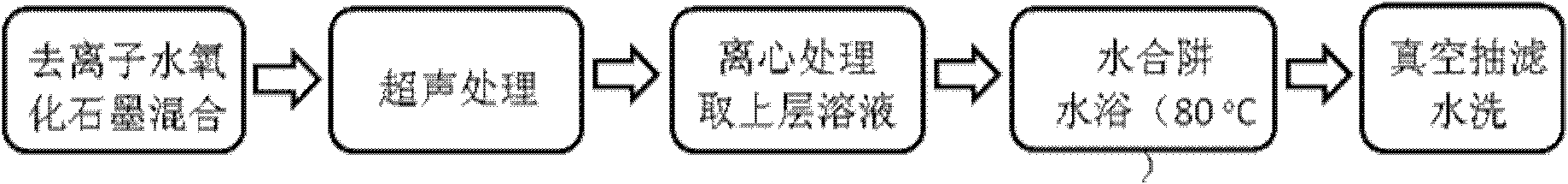

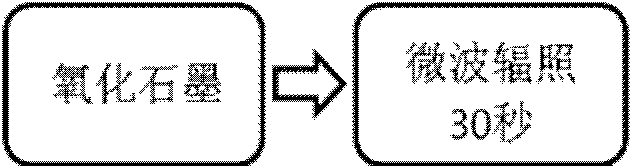

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the present invention prepares the method for graphene material with microwave irradiation in vacuum or inert gas environment, comprises following preparation steps:

[0044] 1. Microwave irradiation steps: take 0.5g of graphite oxide particles (particle size 1-300mm) and place them in the vacuum chamber 6 of the microwave chamber 3, close the vacuum chamber top cover 4; close the first valve 1, and open the second valve 2 ;

[0045] 2. Turn on the mechanical pump 5 to pump the air pressure in the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0046] 3. Close the second valve 2 and open the first valve 1; inject 99.999% nitrogen into the vacuum chamber 6 until the air pressure is higher than 100 Torr;

[0047] 4. Close the first valve 1, open the second valve 2, and pump the air pressure of the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0048] 5. Repeat steps (3) and (4) twice to drive out the residual oxygen in the vacuum chamber;

[0049] ...

Embodiment 2

[0052] Embodiment two: the present invention prepares the method for graphene material with microwave irradiation in vacuum or inert gas environment, comprises following preparation steps:

[0053] 1. Microwave irradiation step: take 10g of graphite oxide particles (1-300 mm in diameter) and place them in the vacuum chamber 6 of the microwave chamber 3, close the vacuum chamber top cover 4; close the first valve 1, and open the second valve 2;

[0054] 2. Turn on the mechanical pump 5 to pump the air pressure in the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0055] 3. Close the second valve 2 and open the first valve 1; inject 99.999% nitrogen into the vacuum chamber 6 until the air pressure is higher than 100 Torr;

[0056] 4. Close the first valve 1, open the second valve 2, and pump the air pressure of the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0057] 5. Repeat steps (3) and (4) twice to drive out the residual oxygen in the vacuum chamber;

[0058] 6. ...

Embodiment 3

[0061] Embodiment three: the present invention prepares the method for graphene material with microwave irradiation in vacuum or inert gas environment, comprises following preparation steps:

[0062] 1. Microwave irradiation step: get 1000g of graphite oxide particles (1-300 mm in diameter) and place them in the vacuum chamber 6 of the microwave chamber 3, close the vacuum chamber top cover 4; close the first valve 1, and open the second valve 2;

[0063] 2. Turn on the mechanical pump 5 to pump the air pressure in the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0064] 3. Close the second valve 2 and open the first valve 1; inject 99.999% nitrogen into the vacuum chamber 6 until the air pressure is higher than 100 Torr;

[0065] 4. Close the first valve 1, open the second valve 2, and pump the air pressure of the vacuum chamber 6 to the limit (4~8×10 -2 Torr);

[0066] 5. Repeat steps (3) and (4) twice to drive out the residual oxygen in the vacuum chamber;

[0067] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com