Anti-corrosive protective film agent for marine boiler

A protective film agent and technology for marine boilers, applied in the field of marine boiler anti-corrosion protective film agent, can solve the problems of poor anti-corrosion effect, short storage time, easy layering and caking, etc. Evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

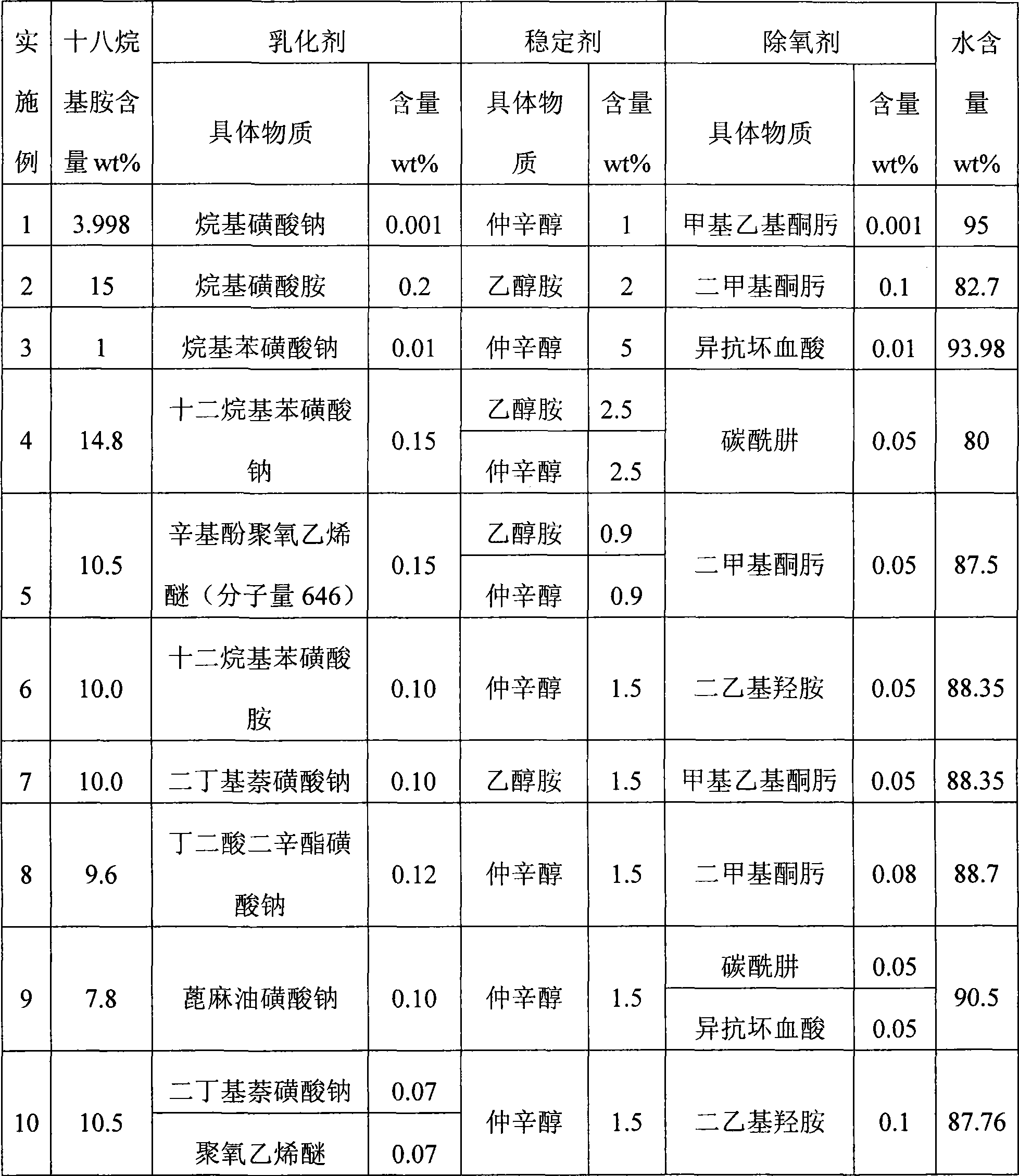

[0026] The following table provides examples 1 to 10 of the anti-corrosion protective film agent in marine boilers of the present invention. First, octadecylamine is pulverized, placed in a container, added with water, stirred while adding, and adding emulsifier, stabilizer and removing agent. Oxygen agent, heated and kept at a certain temperature (temperature and time: temperature 55 ° C ~ 90 ° C, time 5 min ~ 120 min) and stirred to form a uniform water emulsion, then the anti-corrosion protection film inside each marine boiler can be prepared agent.

[0027] Embodiments 1-10 of the anti-corrosion protection film agent in the marine boiler of the present invention

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com