Polyimide/rod-like clay nano-composite film and preparation method thereof

A rod-shaped clay and polyimide technology, which is applied in the field of polyimide/rod-shaped clay nanocomposite film and its preparation, can solve the problems of affecting the strength of the composite film, limited clay dispersion ability, complicated preparation process, etc., and achieve excellent thermal Stability, prevention of agglomeration, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

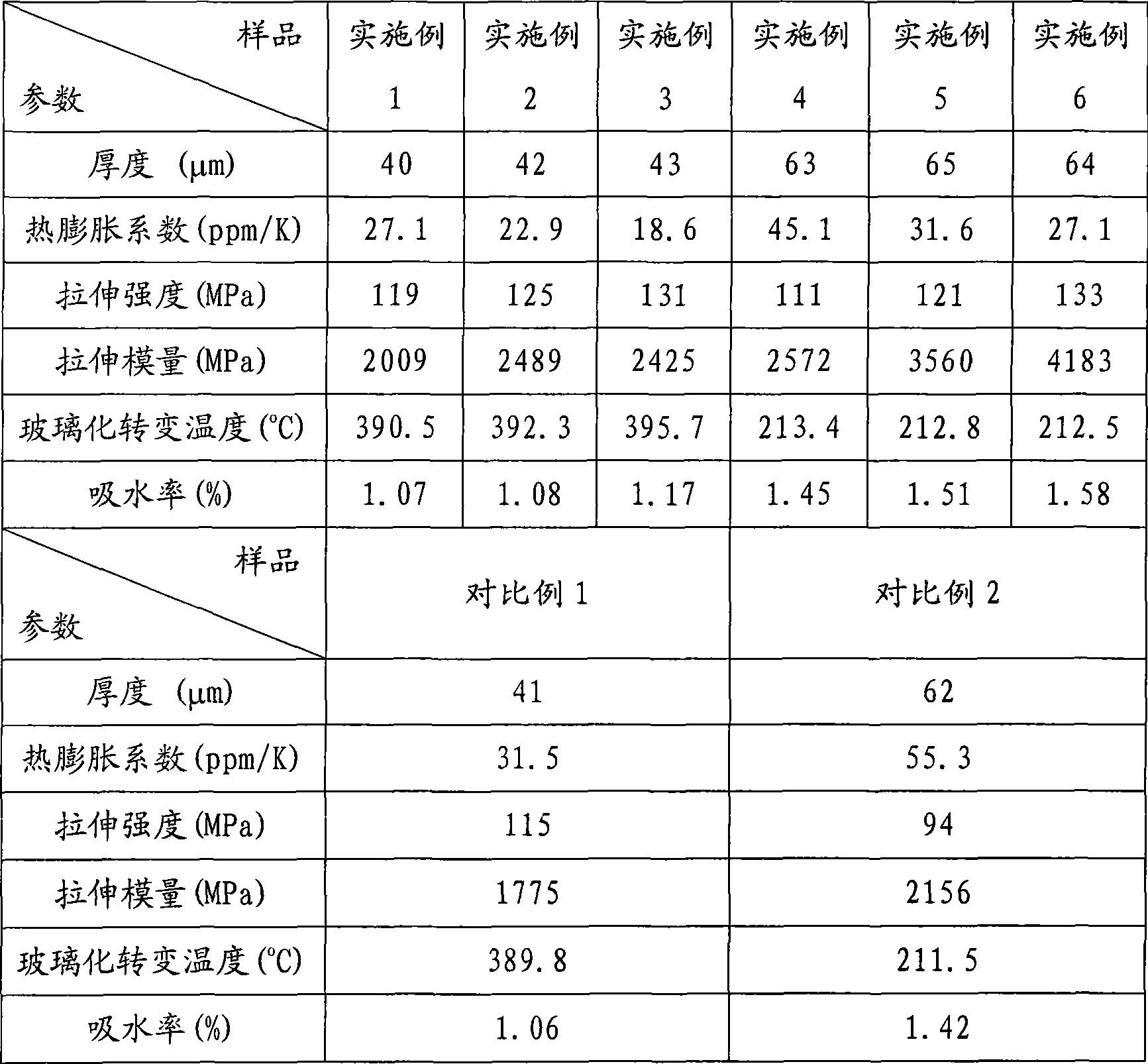

Embodiment 1

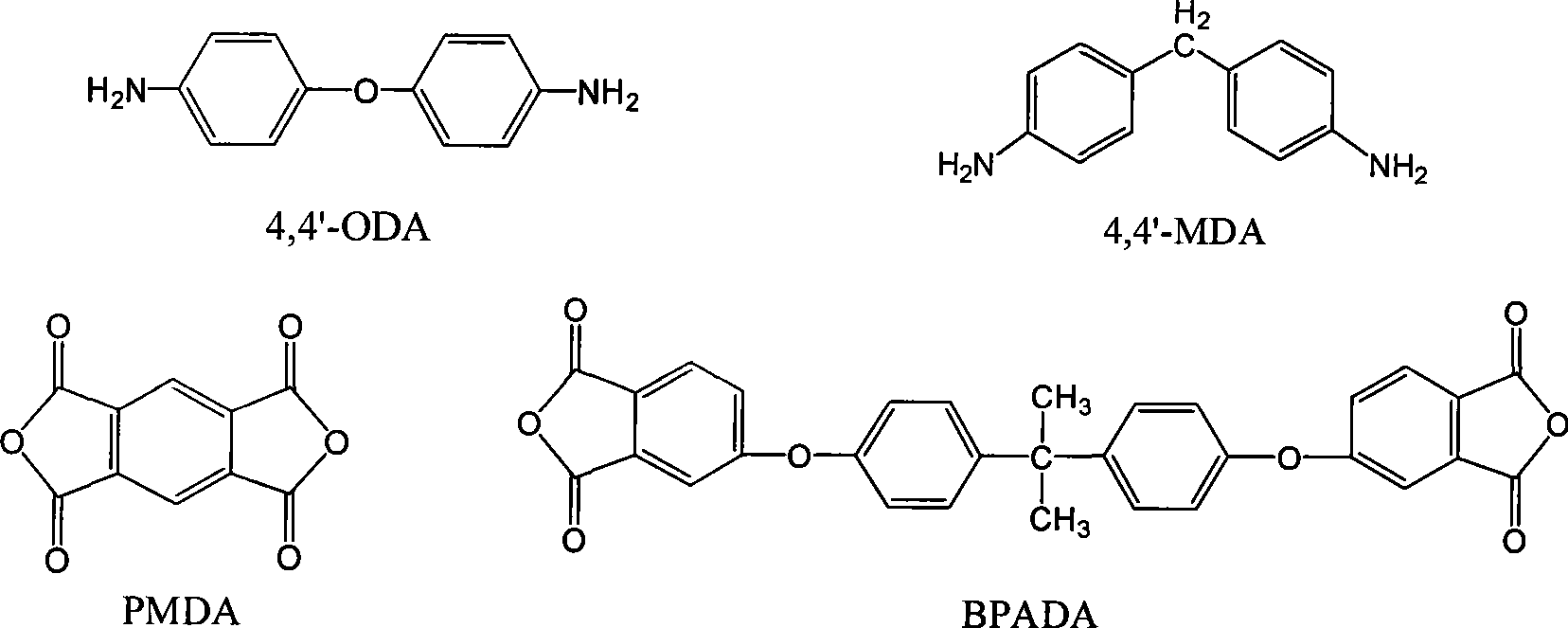

[0026] 1) Add 158g of sepiolite to 30ml of N,N-dimethylacetamide, and ultrasonically disperse it under stable mechanical stirring for 3 hours, then add 1.50g of 4,4'-diaminodiphenyl ether, and wait for 4,4 After '-diaminodiphenyl ether was completely dissolved, 1.65 g of pyromellitic dianhydride was added, and the polymerization reaction was mechanically stirred at 15° C. for 2 hours to obtain a polyamic acid (10% solid content) / sepiolite mixed solution;

[0027] 2) Put the mixed solution to stand for defoaming, pour it on a glass plate to scrape and coat it to form a film, and dry it in an oven at 50°C for 10 hours, then transfer it to a curing oven for thermal imidization. The heating program is: from room temperature Raise the temperature to 135°C within 1 hour and keep the temperature for 2 hours, then raise the temperature to 300°C within 2 hours and keep the temperature for 3 hours, cool to room temperature, peel the film from the glass plate to obtain (4,4'-ODA-PMDA) pol...

Embodiment 2

[0028] 1) Add 0.252g of sepiolite to 30ml of N,N-dimethylacetamide, and ultrasonically disperse it under stable mechanical stirring for 3 hours, then add 1.50g of 4,4'-diaminodiphenyl ether, and in 15 ℃ mechanically stirred and polymerized for 2 hours to obtain a polyamic acid (10% solid content) / sepiolite mixed solution;

[0029] 2) method of operation is the same as step 1 in embodiment 1), obtains (4,4 '-ODA-PMDA) polyimide / sepiolite (8%) nanocomposite film

Embodiment 3

[0031] 1) Add 0.378g of sepiolite to 30ml of N,N-dimethylacetamide, and ultrasonically disperse it under stable mechanical stirring for 3 hours, then add 1.50g of 4,4'-diaminodiphenyl ether, wait for 4, After 4'-diaminodiphenyl ether was completely dissolved, 1.65g of pyromellitic dianhydride was added, and the polymerization reaction was mechanically stirred at 15°C for 2 hours to obtain a polyamic acid (10% solid content) / sepiolite mixed solution, After static defoaming;

[0032] 2) The operation method is the same as step 1) in Example 1 to obtain (4,4'-ODA-PMDA) polyimide / sepiolite (12%) nanocomposite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com