Direct current cable for subway

A DC cable, subway technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of not taking into account the longitudinal water resistance of the conductor and other problems, and achieve the effect of avoiding conductor oxidation, enhancing flexibility, and good UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

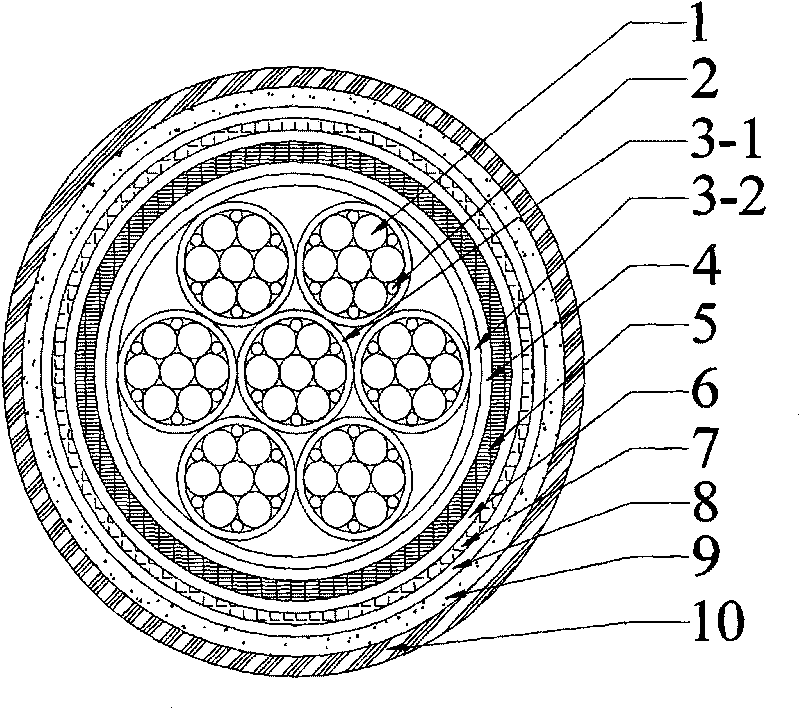

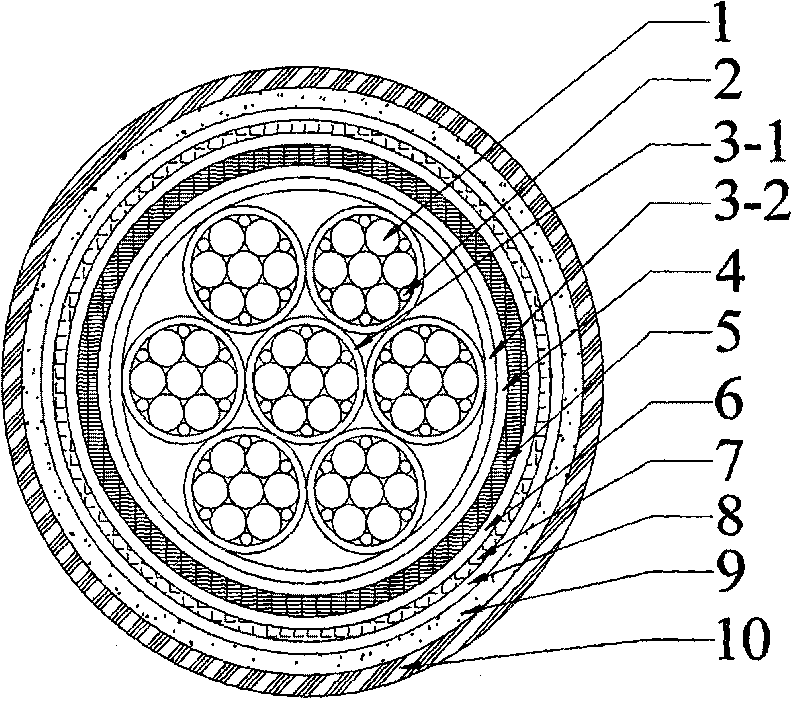

[0019] see figure 1 , a direct current cable for subway, which includes a conductor 1, the conductor 1 is made of tinned copper wire, the strand is made of multiple tinned copper wires twisted together, the water blocking yarn 2 is entrained between the tinned copper wires, the power core It is composed of multiple strands of double-sided semi-conductive resistance hose 3-1 wrapped vertically, the power core is wrapped with two layers of double-sided semi-conductive resistance hose 3-2, and two layers of double-sided semi-conductive resistance Water belt 3-2 is polyester film belt 4, polyester film belt 4 is heat-resistant 105°C high-strength flame-retardant EPDM insulating glue 5, heat-resistant 105°C high-strength flame-retardant EPDM insulating glue The outside of 5 is the expansion type semi-conductive resistance hose 6, the outside of the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com